Heating floors. Electric heated floor. Installation of electric underfloor heating

Underfloor heating cannot be called an achievement modern technologies, such systems were equipped in ancient Roman times. This has been repeatedly confirmed by excavations. Russia is a country where the climate is quite severe, which is why the heating of housing plays a rather important role. Recently, underfloor heating has become popular, which is especially true for the field of individual housing construction. Their use gives the premises a unique comfort and coziness. If you also decide to use this method of creating a warmer climate inside your house or apartment, you can choose water or electric floors.

Modern solution

Warm floors powered by heating are more widely distributed today, this is due to the fact that they are environmentally friendly, have a low cost and are durable. Such a system can be present not only in an apartment, but also in an office, as well as a warehouse or industrial premises. The technology allows you to heat quite large areas, due to this, optimal circulation of heated air is guaranteed, the temperature at different points of the room remains the same.

Pros of using

Floor heating eliminates drafts, and if it is installed in a room where the ceiling height varies from 3.5 to 5 meters, then such a system will not have an alternative, this is especially important for warehouses where it is required to maintain the desired temperature. It is noteworthy that to all the advantages of such a floor, you can add the possibility of arranging it under any kind of topcoat.

The device of a heat-insulated floor working from heating

Underfloor heating, built in this way, is a system created from plastic pipes. They must have a small diameter, metal-plastic or plastic can be used as a material. These materials have high thermal conductivity, low resistance and impressive flexibility. The length of the pipeline can vary from 40 to 500 meters. Such pipelines are made as a whole, which is why the possibility of leakage at the joints is completely excluded.

Floor heating, created according to such a scheme, must maintain a certain temperature, for this a coolant mixing unit is introduced into the system, it can include a pump, a collector, and a temperature sensor controller.

main sources

The above system can be operated from two sources, namely individual gas equipment or central heating system. It is important to remember that connection to the central system in a multi-storey building is prohibited, because then there will be a high load, a water hammer may occur. This can be done after agreement with the experts in your field, this is relevant only for houses of new series, where there is a separate riser for pumping out the coolant in the event of a breakthrough in the heating system. At the same time, heat meters are installed. Preferred alternative ways when the water parameters are set individually, in this case they will not depend on the central heating.

Operating principle

Floor heating works according to a certain principle, it is quite simple and lies in the fact that a coolant is pumped through the collector by a pump under slight pressure along the length of the laid pipeline. The top coat, which has a high thermal conductivity, heats up and gives off heat to the interior of the room. In this case, the air temperature at the floor surface will be higher than at the height of human growth. Through the return pipe, chilled water enters the riser of the central heating system, it can also be gas equipment for heating.

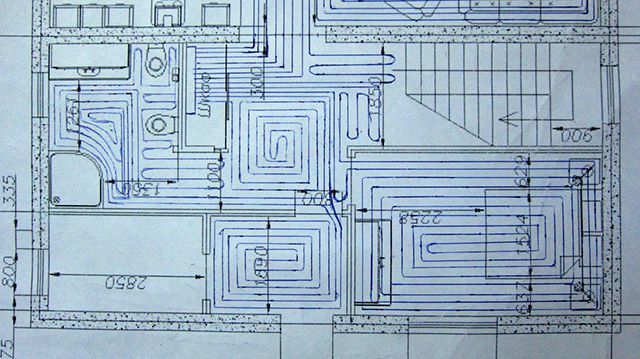

Installation diagrams

Underfloor heating systems are usually installed according to one of the existing schemes, these can be thin, light or concrete floors. In the latter case we are talking about the main system, which is covered with load-bearing reinforced concrete floors, while a concrete-based screed is used as a warm distribution layer. It will provide the maximum possible heat transfer. This system is also called jellied or wet, it is as efficient and reliable as possible. This method provides maximum heat transfer, which covers the heat loss of the room. Such a floor has high strength, is cheap, comfortable to use, environmentally friendly and hygienic.

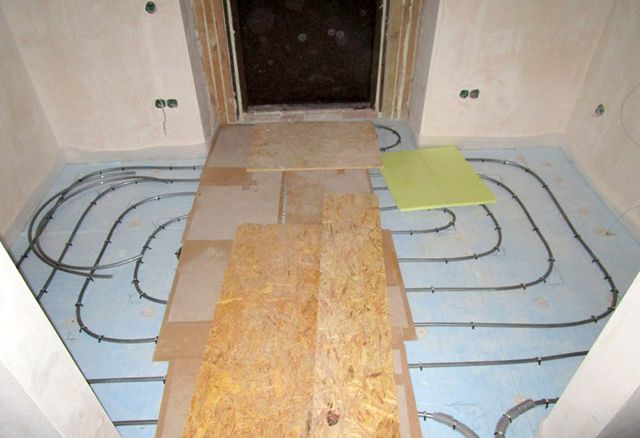

Floor heating systems can be installed in rooms where there are no reliable reinforced concrete floors. In this case, it is better to use a dry screed, it can be polystyrene or wooden floor. Chipboard is used as a basis or they are stacked with plates and have special grooves for the pipeline. The next layer is a gypsum fiber sheet, the main advantages in this case are the high speed of work, small thickness and the absence of costs that are usually associated with concreting.

If you use a dry method, then you do not have to wait about a month until the screed hardens, in addition, its thickness will be equal to the limit from 35 to 60 mm. The disadvantage of such a scheme for arranging the floor is its low heat transfer, it can reach a maximum of 60 W / m 2, one cannot fail to mention the high cost, which depends on the installation price. These systems are usually used in renovations, the need to carry out work in a short time, with a low height of the room, as well as in buildings with wooden floors.

Alternative Solution

A thin scheme is used when arranging the floor in small rooms, the area of \u200b\u200bwhich does not exceed 7 m 2, this includes kitchens, toilets and bathrooms. In this case, a woven substrate is laid, on which a pipeline of small diameter, up to 8 millimeters, is mounted. The top cover is usually a copper mesh.

The limitation of the use of this scheme is due to the high hydraulic resistance, because the pipes will have a small diameter, which means that a high load will be placed on the heating system.

You can independently implement the heating of a private house, warm floors sometimes become the only right solution. However, before installing them, it is necessary to dismantle the old screed, reaching the base. Waterproofing is laid on the cleaned surface, it is laid not only around the perimeter, but also between the contours, if there are several of them. The method of insulation should be chosen depending on the target orientation of the system. If it is an addition to the main one, then polyethylene foam is sufficient, one side of which is covered with foil. If we are talking about an apartment, from the bottom of which there are heated rooms, then it will be enough sheets of expanded polystyrene or extruded polystyrene foam, their thickness can vary from 20 to 50 mm.

Floor for a room with a cold ceiling

It is possible to make heating in the floor of a private house, when there is a basement or soil below, using a heater in the form of an expanded clay or expanded polystyrene mound, the thickness of the latter can reach 100 mm, while the minimum value is 50 mm. A reinforcing mesh must be placed on top of the insulation, it will not be fixed into the screed layer, among other things, it will be possible to fix the floor heating pipe on the mesh. Sometimes special clips or fastening strips are used.

Choice of materials and devices

Floor heating of a private house can be realized from the heating system. However, you may also need:

- water heating boiler;

- Ball Valves;

- manifold with tuning system;

- various fittings;

- pipes;

- injection pump.

The latter may be present in the composition of the boiler, but as for the collector, it must be equipped with a system for adjusting underfloor heating. Fittings will be needed to lay the main route, they will allow you to equip the system from the collector to the boiler. It is important to take seriously the choice of material for pipes. If you decide to prefer polypropylene products, then it is best to choose reinforced with fiberglass, since polypropylene has a high linear expansion when heated. Polyethylene does not expand as much, so it has recently become widespread.

More about pipes

You can independently implement such heating. It is best to install a warm water floor using pipes whose diameter varies from 16 to 20 mm. The pipe must withstand temperatures up to 95 degrees Celsius, while the maximum possible pressure must be 10 bar. It is not at all necessary to purchase expensive options with additional layers and oxygen protection. This applies to those people whose main task is to reduce the cost of installing underfloor heating.

Work technology

If you decide to equip underfloor heating in a private house, you must adhere to a certain methodology, it provides for the implementation of preparatory work, the laying of a damper tape, a heat-insulating layer and a pipeline. Preparation involves cleaning surfaces from dirt and debris, cracks and crevices must be sealed with concrete mortar. It is important to make sure that the irregularities do not exceed 5 mm, otherwise air will occur during the operation of the system, and heat transfer will decrease.

If the subfloors do not differ in evenness, they must be filled with a rough screed. The next step is to lay the damper tape, it will compensate for the thermal expansion of the screed. In order for the heat not to go to the neighbors, a layer of insulation should be laid. These can be foam or polystyrene mats, on the surface of which there should be clamps for pipes. The thickness of the material will depend on the thermal load: the more impressive it is, the thicker the insulation layer should be. The minimum value is 30 mm. Next, heating pipes are laid in the floor. They should be fixed in the grooves of the insulation using one of the three mounting schemes. It could be styling:

- snake;

- double helix;

- normal erase.

The last option is the simplest and most reliable. The system should be pressure tested or subjected to hydraulic tests, this will make sure of the strength and tightness, and it is necessary to carry out these works after installing and connecting the heating circuit. Water must be supplied under positive pressure.

The warm floor from heating must be filled with a concrete screed; for this, cement should be prepared, the grade of which is M-300 or higher. It is important to add a plasticizer, on square meter there will be a sufficient volume of 0.6-1 l. The concrete screed should close the pipeline, the thickness should not be more than 15 cm. It is important to pour the solution onto warm pipes so that they do not tear the concrete when they expand. After 28 days, the system can be started, the water temperature should rise gradually, the maximum level can be reached only on the third day of heating. After completing all the above work, you should proceed with the installation of a decorative floor covering, it can be a laminate, linoleum, ceramic tile as well as carpet.

Conclusion

Heating in the floor in the house is inert, but this characteristic can do a good job. If for some reason boiler equipment is not able to heat water for some time, the system will give off heat to the premises. But you need to be prepared for the fact that after the first start, warming up may take several days. That is why those people who have been using such heating systems for several years are advised to turn on underfloor heating at the first frost, this will prepare them for the cold.

Unlike the usual radiator heating, water heating has become fashionable relatively recently. This system is designed for floor heating both in a private house and in an apartment. It is used simultaneously as both a radiator and a heat accumulator. It is able to evenly distribute all the generated thermal energy and also save a lot on it. Many are already thinking about how to make a warm floor from heating.

First of all, you need to figure out where you can install underfloor heating. Most often it is mounted in country houses, which is due to two main reasons. And the first of them - in apartments that are connected to central heating systems, the installation of underfloor heating is usually prohibited. This is explained by the fact that there is a threat of increasing hydraulic resistance.

The second reason is that if it is connected to a centralized heating system, then the water, having passed through all the pipes of the warm floor, will return to the common riser almost cold.

Given these nuances, in apartments it is best to use electric floor heating, and in country houses - on the contrary, water. In addition, experts recommend using the latter only in insulated buildings or rooms.

Warm floor in the apartment

Many experts do not advise making water floors in multi-storey buildings. But still some of them say that there is an exception to the rule.

How to make a warm floor from heating in an apartment without harming neighbors? There is nothing simpler, but this only applies to housing on the first (with the upper wiring) or the last floor (with the lower wiring of hot water). The fact is that in these apartments the water goes to the return line and it is quite suitable for floor heating, while the heat in other apartments does not decrease.

There is another heating scheme with warm floors without prejudice to the interests of other users. It can be used in a combined bathroom or in the bathroom. But in this case, there can be no question of any temperature adjustment. It directly depends only on the water in the central heating network, and if the latter is too hot, then the floors will warm up accordingly.

Advantages

The use of underfloor heating in apartments and especially in private houses has many advantages over conventional radiator heating. The first of them and perhaps the most important is the most comfortable climate in the house. Uniform heating of the air in the room through the entire surface of the floor almost completely eliminates the risk of colds. The heat emanating from it does not allow the legs to overcool.

A warm water floor makes it possible to expand the space of the room by removing radiators from under the windows. This system is completely hidden under the flooring, does not take up space, and also allows you to make windows in the entire wall.

It can significantly reduce operating costs, as a temperature drop of 2 or 3 degrees will not entail any physical discomfort. In addition, the "warm floor" heating system evenly heats the entire room without creating chilled or overheated zones.

Another advantage is the absence of so-called convection currents. The radiator heating system works in this way - the air is heated, which rises and remains under the ceiling, and when it cools against the opposite wall, it descends to the floor. This is how a constant air cycle occurs, raising and carrying a lot of fine dust.

It should be noted that a warm water floor is an extremely reliable and safe system in terms of operation. Enough simple design and a well-established technology of creation and installation allows it to serve faithfully for a period of at least 50 years, and this is without additional operational maintenance.

Project implementation

Warm floors, where the source of heating is water, are considered a low-temperature heating device. The maximum heating of the liquid in such a system is no more than 55 ⁰С. And given that water pipes are not only under a layer of concrete mortar, but also finishing material, then the floor surface will be only 35 ⁰С. This temperature is enough to feel comfortable. But at higher rates, they will begin to arise discomfort when the skin of the feet touches the coating that is too hot.

Heated water floors are always convenient and comfortable. Especially if you do not need to install a water heating boiler. In private houses and apartments with existing radiators, you can make underfloor heating from central heating. To do this, a number of conditions must be met.

In any case, the heating system must be equipped with a circulation pump. If it is still not there, then it is best to purchase and install it than to make a gravity structure with a certain slope of the floor surface. The system can be of two types: one-pipe or two-pipe. In the first case, the supply pipe is connected after circulation pump, and the return - in front of the pump.

In addition, it is necessary to calculate the length of the contours. For a single-pipe type, it should not exceed 30 m, and for a two-pipe type - 50 m. It happens that the circuit is longer, then it is divided into several parts and laid in parallel or in different zones.

Required Items

Heating systems, where the connection of a warm floor to the boiler is provided, should consist of several main elements:

● metal-polymer or polymer pipes;

● circulation pump;

● thermal insulation materials;

● heating boiler;

● fasteners, manifolds and fittings;

● control fittings and shut-off ball valves.

Such heating system you can not only mount it yourself, but also make preliminary calculations. If the main source of heat is exclusively a water floor, then it is better to order the project from specialists.

Varieties

Water heating, which is installed on a plane, can be concrete and floor. The first type involves the installation of a warm floor using concrete screed, and the second - without it. Flooring must be laid on special aluminum plates, pre-coated with a polystyrene gasket, or on a wooden floor, as well as on pre-installed logs. But still the most common and popular is the concrete screed.

Connection

The most simple circuit connecting a warm floor should look like this: the first collector combines the water supply pipelines, and the second, in turn, reverse. They are also connected to pipes with the coolant itself. This option has one significant drawback - it is simply impossible to regulate the temperature of the water coming from the boiler.

The maximum that can be done is to close the valves, but this does not solve the problem itself. Some floor coverings have been known to deteriorate if heated to over 30°C. Therefore, it is desirable to provide for temperature control.

In order for the connection scheme of the warm floor to be complete, you need to add a few additional elements, such as a three-way mixer or pump-mixing unit, a circulation pump, an air vent and a drain cock.

In addition, instead of shut-off valves, it is better to install thermostatic mixers. By changing the size of the paraffin rod, it allows the faucet capacity to function without sudden drops.

The presence in the scheme of pumping mixing unit is also necessary. It adds chilled water to the supply when it needs to lower its overall temperature so that it does not exceed acceptable limits.

It is worth paying special attention to the installation of the mixing pump. It must be between the supply pipe and the supply manifold. To its third output, the liquid output from the discharging collector is connected. This allows the pump to take some of the chilled water and add it to the supply.

Mounting order

Before proceeding with the installation of the system, you need to know the sequence of how to make a warm floor from heating according to all existing rules.

The installation procedure consists of several main stages:

● establishment of a collector group;

● leveling of the floor surface and its preliminary preparation;

● laying pipelines of the future heating system;

● temperature control.

Collector group

Work on the installation of underfloor water heating begins with the installation of a manifold cabinet, which should be located at the same distance from the end consumers. For example, if the warm floor will be located on the territory of two rooms, then the box must be placed in the middle between them.

In order for the collector cabinet not to spoil the interior of the room, it is hidden inside the wall. During the preparatory activities, a special niche is made with the help of a grinder or a perforator. Its size should be slightly larger than the dimensions of the cabinet, and it should be placed near the floor.

The auxiliary water floor system consists of a certain number of pipelines. They are joined in a collector cabinet and pulled from the main heating system. The box must contain both shut-off and control valves.

After installing the collector cabinet, supply and return pipelines are brought into it. Goes first hot water from the central system, and according to the second - already cooled is returned. At the ends of these pipelines, shut-off valves are installed in the form of valves or ball valves, with which it will be possible to turn off the water supply at the right time. The transition between them is a special compression fitting.

All the constituent elements of the collector cabinet are connected to a rail with outlet pipes, to which the pipelines forming the circuit are drawn. As you can see in the photo, the scheme for connecting a warm floor is quite simple, so it can be done without the help of a specialist.

Preparing the floor

First of all, it is necessary to check the horizontal plane on which the heating system will be located. The warm water floor is laid only on a previously prepared and leveled surface. And this stage of work should not be neglected. The uniformity of heating directly depends on the same layer of screed over the entire surface of the floor.

After leveling, proceed to laying the waterproofing layer. Then, a special damper tape is glued to the walls around the perimeter of the room, which can compensate for the linear expansion of the screed or underfloor heating. The excess is cut off.

Heating "warm floor (water)" is installed only with the use of heat-insulating mats made from materials such as aerated concrete, veloterm, technical cork, mineral wool or styrofoam. They prevent heat loss.

Mounting

At this stage, they are engaged in fixing the pipelines of the thermal circuit. The most popular way is to lay and fasten pipes to a special masonry mesh made of metal and laid on a heater. The pipeline is fixed on it with a knitting wire.

In the event that the thermal circuit exceeds a length of 70 m, then a second one is made. The pipeline is always carried out according to this principle - from the colder (windows and doorways) to the warmest zones.

Examination

Hydraulic tests of already laid pipes are carried out only before they begin to fill them with a cement-sand mortar. They are considered successful if there are no leaks in the pipeline at a water pressure of 6 atmospheres. The time required for complete drying of the concreted floor is at least 10 days. Only if all installation conditions are met water heating will be as efficient, reliable and durable as possible.

Adjustment

The temperature of water floor heating can be adjusted in two ways: manual and automatic. The first is carried out using a ball valve, and the second - by electric drives. It must be said that automatic adjustment is the most effective for water heating.

When building a new home, the question inevitably arises of what type of heating to choose. Considering all the pros and cons various kinds space heating, you can come to the only correct decision that there is simply no better system than water-heated floors. In addition, it can be connected to almost any heat source using various energy carriers. And since it’s not difficult to make a warm floor from heating yourself, you can also save a decent amount of money.

Underfloor water heating, in contrast to the radiator familiar to most inhabitants, appeared relatively recently.

This system is designed to heat the floor in an apartment or house, using it as a heat accumulator and a heat emitter at the same time. Underfloor heating allows you to evenly distribute thermal energy and achieve significant savings (up to 30%).

Among the undoubted advantages of water heating, one can single out not only cost-effectiveness, the creation comfortable temperature and more effective use living space (due to the lack of traditional radiators), but also the possibility of do-it-yourself installation.

This article is entirely devoted to describing the principles of operation and the sequence of installation of water heating.

The device of warm water floors

Underfloor heating allows you to evenly distribute heat energy and achieve significant savings. Click to enlarge.

Water floor heating involves the use of a heated coolant as the main source of thermal energy, which heats the room by passing through pipes laid in the floor.

Warm water floors are most often found in country houses. This situation has arisen for a number of good reasons.

Firstly, in an apartment connected to a central heating system, it is forbidden to install underfloor heating because of the threat of increasing hydraulic resistance.

Secondly, you should not connect to the pipelines of the hot water supply system, since the water, after passing through the underfloor heating system, returns to the common hot water supply already cooled.

Thus, in a city apartment it is most advisable to use an electric floor heating, and in country house- water. Water heating underfloor heating should only be used in insulated buildings and premises.

It is not necessary to carry out preliminary waterproofing work (most component manufacturers do not insist on carrying out this procedure).

Varieties of water floors

Water heating, mounted under the floor, can have the following varieties:

- Concrete.

- Flat.

The first option involves laying a water floor using a concrete screed, the second - without laying a screed.

The decking floors can be laid on aluminum plates through a polystyrene insert (polystyrene system) or on a wooden subfloor or logs (wooden system).

In this article, we will dwell in detail on the sequence of installation of a concrete water floor, since it was he who received the greatest distribution and popularity.

Typical composition of a water heating system

Almost any heating system that incorporates a warm floor (water) is represented by the following main elements:

- Polymer or metal-polymer pipelines.

- Thermal insulation materials.

- Circulation pump.

- Shut-off valves (ball valves) and control valves (control valves).

- Collectors, fittings and fasteners.

The heating system, which performs an auxiliary function, can not only be mounted with your own hands, but also provides for an independent preliminary calculation.

Composition of the heating system. Click to enlarge.

In the case when the main source of heat is heating, represented exclusively by one water-heated floor, it is recommended to order the development of a design solution from specialized specialists.

The main stages of installation of a concrete water floor

Water floor heating, produced independently (with your own hands), must necessarily include the sequential implementation of the following steps and operations:

- Collector group installation.

- Preliminary preparation of the floor surface.

- Laying pipelines of the heating system.

- Temperature regulation.

Consider the main issues related to the implementation of the above works.

Collector group installation

Work on the installation of a water floor must begin with the installation of a special collector cabinet, which should be located at an equal distance from the end users.

So, if it is necessary to install underfloor heating in two rooms, then the manifold cabinet should be installed in the middle of the rooms.

To achieve the desired aesthetic effect, the collector cabinet is installed inside the wall.

The preparatory operation in this case is the preparation of a special niche, carried out with the help of a perforator and a grinder. The dimensions of this niche should slightly exceed dimensions cabinet, and should be placed near the floor surface.

What is the main purpose of the manifold cabinet?

The system (main or auxiliary) of water floor heating includes a certain number of pipelines that are joined exactly inside the manifold cabinet, coming from the central heating system. Control and shut-off valves are an indispensable attribute of manifold cabinets.

collector device. Click to enlarge.

After the direct installation of the collector cabinet, two main pipelines must be brought into it - supply and return.

The supply pipeline is used to transport the coolant from the central water supply system. The cooled coolant returns through the return pipeline.

At the end sections of the supply and return pipelines located in the manifold cabinet, shut-off valves (ball valves or valves) are installed.

Their main purpose is the forced shutdown of the coolant supply. To join stop valves a transitional compression fitting is applied to the supply and return pipelines.

The resulting system, consisting of supply and return pipelines, shut-off valves and a compression valve, should be connected to a manifold rail with a number of outlet pipes.

These branch pipes serve for connection of the pipelines forming a contour of a heat-insulated floor. The hole formed on the other side of the collector manifold piping remains open.

This hole can be closed using an ordinary plug or a drain inspection valve, which is also designed to bleed air bubbles when the system is "aired". As you can see, the installation of a manifold cabinet is quite possible to do it yourself.

Preliminary preparation of the floor surface

The water floor, mounted directly from the central heating system, must be laid on a previously prepared surface.

Surface preparation should begin with debris removal and checking the surface for horizontalness, carried out using a two-meter building level.

In no case should the horizontal check be neglected. It must be done so that the protective layer of the screed is the same, and the heating is uniform.

Leveling the floor should be started if the heights located at the corners exceed one centimeter. Next, the waterproofing layer is laid (if necessary) on the previously leveled surface.

The walls should be glued along the entire perimeter with a special damper tape designed to compensate for linear expansions to which a warm floor is exposed (floor screed). The protruding remains of the tape after pouring the floor must be cut off.

Floor preparation for heating installation. Click to enlarge.

Heating, which is a water heated floor, necessarily includes heat-insulating mats that prevent heat loss.

Underfloor heating can be installed using mats made from the following materials:

- Styrofoam.

- Mineral wool.

- Aerated concrete.

- Technical traffic jam.

- Veloterm.

Heat-insulating mats that protect against heat loss the floor located in the bathroom or toilet with self-installed water heating must be moisture resistant.

Pipeline installation

Installation of pipelines of a water heating system in a country house or in an apartment, as well as the implementation of all other stages, can be done by hand.

Highlight this stage- fixing the pipelines of the future thermal circuit, which contain all the heated rooms.

One of the most popular ways is to fasten a pre-laid pipe to a metal masonry mesh laid directly on the insulation.

Fixation of pipelines, which contain water floors heated to the required temperature by a coolant, and a metal mesh is carried out with a knitting wire.

Underfloor heating may include a thermal circuit, the maximum possible length of which does not exceed 70 meters. In the case when it is not possible to meet this distance, warm floors should have a second circuit.

The process of laying pipes for underfloor heating. Click to enlarge.

For the installation of a two-circuit system, a collector rail with a large number of taps should be used, the total length of the pipelines of one circuit should not exceed the length of the pipelines of the other.

Laying of pipelines must be carried out from the coldest zones towards warmer ones. Cold zones include window and door openings.

When installing heating with your own hands, you should choose pipes from the most reliable supplier.

Hydraulic tests of the laid pipelines must be carried out before pouring the floor with a cement-sand mortar.

Pipelines are considered to have passed the test if no leaks are detected at a pressure of 6 atmospheres, and there is no pressure drop. The time required for the complete solidification of the cement-sand mortar should be at least 10 days.

Pipe laying options warm floor. Click to enlarge.

Only under these conditions will the water heating installed by you under the floor be reliable, durable and efficient.

Temperature control

Underfloor heating using heated water (water) provides for two ways to adjust the temperature:

- Manual regulation (using shut-off valves).

- Automatic regulation (using electric drives).

Warm floors (in particular, the water heating we are considering) are more efficient with automatic control.

Final provisions

Water floor heating is more rational to install in the house, and not in the apartment. The latter option has the right to exist, but is associated with some problems.

In both the first and second cases, it is enough to simply mount the system with your own hands, using the sequence of actions described above and some specific nuances.

In fairness, it should be noted that full-fledged heating of the house can be done not only by radiators. Underfloor heating does the job just as well. In Ukraine, this method of heating is not yet very common. And the main reason lies not in the limited financial possibilities of compatriots, but in an elementary unwillingness to destroy the stereotypes formed over decades. Believe that the house can be heated without traditional batteries, not everyone is capable yet. But in vain, because underfloor heating is a modern and energy-efficient alternative, the advantages of which have long been recognized in Europe. In particular, in Norway, the birthplace of underfloor heating, up to 80% of buildings are equipped with underfloor heating.

So what are the benefits of these systems? Principle of operation district heating next: the heat from the radiators rises to the ceiling, and more cold air drops to the floor. While the lower layers of air heat up, the upper ones cool (and some of the heat is also given off to ventilation). Then the process is repeated. Convection currents create a rather controversial atmosphere, corresponding to the saying "Keep your feet warm and your head cold" exactly the opposite. As a result, a constant draft at floor level causes discomfort and unforeseen energy costs for heating. When heating with the " warm floor» air moves in only one direction - from bottom to top. The large area of the "heater" provides uniform heating of the air in the room. Moreover, the very warm air always located at the bottom, excluding drafts. With an underfloor heating system, energy consumption is reduced by about 20%. Also, the system warm floor» is absolutely invisible, therefore it does not affect the design of the room, and has a large guarantee period indicating its quality and durability.

To date, there are two types of underfloor heating: water and electric. Regardless of the type, the system includes heating cables (circuit), a thermostat with a temperature sensor, thermal insulation and fasteners. They are also mounted in the same way - in the floor screed. But there are also differences.

Water heated floors require an additional purchase of a boiler, which increases the cost of installing the system. But when you consider that they are more economical to use, the final amount equates to the cost of electric models. AT suburban construction water systems have an indisputable advantage, because the problem of energy efficiency becomes relevant precisely in large areas. And in summer time they also help cool the room with cold water.

Electric heated floors are easy to install, do not require additional equipment and preventive maintenance during operation. But use electrical systems less cost effective. Therefore, they are usually installed in separate rooms of the house (in the hallway, bathroom or kitchen).

Many companies supply floor heating systems to the Ukrainian market, including Aquatherm, Rehau (Germany), Ceilhit (Spain), Devi (Denmark), Easy Heat (Canada), Ensto (Finland), Fenix (Czech Republic), KAN (Poland) , Nexans (Norway), ThermoTech, Wirsbo (Sweden), Nash Comfort, Teplolux (Russia), NPP Eleter (Ukraine), etc.

As you lay the floor, so it will serve

Installation of the system " warm floor» requires special training, therefore it is carried out by qualified workers. But knowing the basic principles and pitfalls of laying will help you control this process and avoid correcting poor-quality work.

The system is laid on the subfloor even before the screed is poured. There are two types of pipe laying: parallel (snake, double snake) and spiral. Parallel laying is suitable for small spaces as well as sloping floors. In this case, the hottest pipe (the place where the coolant enters the coil) is located in the coldest zone, for example, at the outer wall. Spiral laying is more suitable for large rooms, as well as for places where the temperature difference is undesirable. The hottest section of the pipe is adjacent to the coldest, so the temperature remains constant throughout the floor area.

The electric heating cable is laid only on a surface free of stationary furniture and floor household appliances, and water pipes can be laid over the entire area (they are not threatened with overheating under heavy objects). There should be no pipelines and electrical cables in the places where the floor heating is installed. The distance from the boundary of the heated area of the room to the heating cable or pipe is equal to half the laying step (the distance between the loop turns). And in areas near the outer walls of the building - the so-called boundary zones - it is desirable to reduce the laying step to compensate for heat loss.

When laying the heating circuit and pouring the screed, make sure that workers do not accidentally damage the system. It will be possible to check its performance only after the screed has completely dried (after 3-4 weeks), and if the system is damaged, you will have to open the floor and mount it again.

The reliability of water heated floors is influenced by another factor - the quality of the water in them. When filling the pipes for the first time, make sure that the workers flush them thoroughly and then start warm water with the addition of 1-2% cleaning agent.

Systems installed in accordance with these requirements usually do not require repair and maintenance throughout their entire service life. True, there are several other factors that affect the serviceability, and most importantly, the effectiveness of underfloor heating:

- correctly selected power of the circulation pump (if there is insufficient power, the longest loop of the circuit will have insufficient water pressure);

- basic adjustment of the distribution manifold (if it is not done, water circulates only in short circuits where there is less resistance);

- a mixing unit adjusted to a given temperature (otherwise the temperature of warm floors will be uncomfortable).

It is advisable to discuss all these nuances with specialists during the installation of the system. Thus, you will protect yourself from unpleasant surprises in the future.

Thermostats for underfloor heating

The thermostat is the only element of the warm floor visible in the interior. The main task of the thermostat is to maintain the set temperature.

Only unlike radiator thermostats, the object of his attention is the temperature of the floor. This helps to avoid situations where the air in the room (for example, in the bathroom or in the kitchen) warms up very quickly, while the floor remains cold. But there are more functional thermostats that have two sensors - air and floor. As a rule, such models are used in systems designed not only for floor heating, but also for heating the entire room (in the absence of other heat sources).

When choosing a thermostat for underfloor heating, remember that its switching power must correspond to the power of the heating system itself. According to modern standards, the maximum power of thermostats is 3 kW (approximately the same amount consumes a washing machine). If power installed system above, you must additionally use a power relay or use several thermostats.

Installation, configuration and prevention

Radiator thermostats are suitable for any known heating system. Their installation is simple and does not require special qualifications (with the exception of a special-purpose series). It is enough to follow the instructions included in the package. But if you have never had to do such work yourself, it is better to seek help from a specialist. Any plumber will install the thermostat without problems, and you can set it up - according to the same instructions.

In the case of underfloor heating, special attention should be paid to the installation of the thermostat. The device is placed on the wall (or built into it - depending on the type) in any convenient place, but not higher than at a distance of 30 cm from the floor. First, holes are made in the wall and floor for installing the thermostat. Power is supplied to the place of its installation. And only then install warm floor. The reliability of underfloor heating systems is 99% determined by the quality installation work, therefore it is better to entrust this work to specialists (including the installation of thermostats).

Setting the thermostat for underfloor heating takes no more than 20 minutes. The set parameters are stored in the unit's memory and are maintained even after a power failure - this is taken care of by the thermostat's battery backup. In addition to the programmed settings, there are additional control buttons that allow you to change the temperature or mode for a certain period of time. When you press the "Restore settings" button, all parameters return to the original time and temperature settings.

Warm floors are considered in our understanding more than modern system heating than radiator heating. However, this is far from the case - they appeared much earlier. Stubborn historical facts indicate that underfloor heating was successfully used in the days of Ancient Rome, in Korea, and in Russia too. True, only stove heating was used at that time, since the system for transporting hydrocarbons through pipes did not yet exist. AT modern world The most economically successful countries widely use underfloor heating, and this is done not only for reasons of obvious comfort, but also takes into account the fact that such heating saves energy resources, the demand for which is growing every year.

This type of heating is not cheap. Parts and labor are very expensive. That is why any zealous owner may have the idea of making a warm water floor with his own hands. Why not? Moreover, the experience of both successful and unsuccessful implementations has already been accumulated enough to give specific recommendations. The purpose of our article is to give specific advice to those owners who are going to make a warm water floor, but at the same time so that they save their money and in the end get what they wanted - comfortable and economical heating.

Why underfloor heating?

Of course, they are easier to implement, they are easier to manage, but the cost of energy carriers makes its own adjustments - this type of heating is much more expensive to operate than a water heated floor. It will take only 4-5 years and a warm water floor will pay off with interest, but only on condition that it is done correctly and correctly. This is what the authors of the article want to tell our readers. Sweeping aside colorful catalogs with expensive equipment, but based only on the experience of people who were able to implement a warm water floor in their home.

Most heating systems currently use natural gas as a heat source - and this is completely logical, since this type of fuel is cheaper than others. And this trend will continue for at least a few more decades. Therefore, warm floors are best implemented with water, the coolant in which is heated by the energy of natural gas combustion. But for this, a number of conditions must be met.

Water floor heating device

A warm water floor is a complex multicomponent system, each part of which performs its own function. Consider its device in the following figure.

Typical design"pie" of a warm water floor

Typical design"pie" of a warm water floor This type of underfloor heating is called “wet” because “wet” construction processes are used in its arrangement, namely, pouring a cement-sand screed. There are also so-called dry warm floors, but they are made mainly. Within the framework of this article, we will consider exactly “wet” warm water floors, since they are much better, although their installation is more difficult.

A warm water floor is mounted on a stable and solid base, which can be a concrete slab or soil. A vapor barrier made of a polyethylene film with a thickness of at least 0.1 mm is laid on the base. The next layer of the "pie" is a heater, as it is best to use extruded, which has a very low thermal conductivity, high mechanical strength and reasonable cost. A cement-sand screed is equipped on top of the insulation, to which a plasticizer is necessarily added - for the mobility of the mixture, ease of installation and reduction of the water-cement ratio. It is desirable to reinforce the screed with a metal wire mesh with a cell pitch of 50 * 50 mm or 100 * 100 mm. In the same place, inside the screed, pipes of a warm floor pass with a coolant circulating in them. It is recommended to make the screed height above the pipes at least 3 cm, however, practice suggests that 5 cm is better, so the strength will be higher and the heat distribution across the floor will be more uniform.

At the junction of the walls to the screed, as well as at the boundaries of the warm water heating circuits, a damper tape is laid, which compensates for the thermal expansion of the screed when it is heated. The floor covering must be specifically designed to work with underfloor heating. The best way out is ceramic or porcelain stoneware, but some other types of coating - laminate, carpet or can also be used with underfloor heating, but there should be a special icon in their marking.

Such coatings, however, require strict adherence to the thermal regime of the floor, which is achieved by using automation - special mixing units.

Requirements for premises where heating with warm water floors will be implemented

The smartest move in construction is when the underfloor heating pipeline is laid even at the stage of building ceilings. This is very successfully used in Germany, Sweden, Norway, Canada, yes, and in other economically successful countries where energy resources are very expensive and therefore they use floor heating, which is 30-40% more economical than radiator heating. It is quite possible already in the finished room, but it must meet certain requirements. Let's list them.

The most correct underfloor heating pipeline is the one that was laid at the stage of building a house

The most correct underfloor heating pipeline is the one that was laid at the stage of building a house - Given the significant thickness of the warm water floor - from 8 to 20 cm, the height of the ceilings in the room should allow the installation of such a heating system. It is also necessary to take into account the value doorways, which must be at least 210 cm in height.

- The subfloor must be strong enough to support a heavy cement-sand screed.

- The base for the underfloor heating must be clean and level. Irregularities should not exceed 5 mm, since drops strongly affect the flow of the coolant in the pipes, they can lead to airing of the circuits and an increase in hydraulic resistance.

- In the room where a warm water floor is planned, all plastering work, windows are inserted.

- Heat loss in the premises should not be more than 100 W / m 2. If they are larger, then it is worth thinking about warming, and not heating the environment.

How to choose a good pipe for underfloor heating

About the pipes of a warm water floor it is written in sufficient detail on our portal. Obviously, for underfloor heating it is better to choose pipes made of cross-linked polyethylene - PEX or PERT. Among PEX pipes, preference should be given to PE-Xa pipes, as they have a maximum crosslink density of about 85% and therefore have a better “memory effect”, that is, pipes after stretching always tend to return to their original position. This allows you to apply axial fittings with a sliding ring, which can be walled up without fear in building construction. In addition, when a pipe is broken, its shape can be restored by heating the problem area with a building hair dryer.

PERT pipes do not have a memory effect, so only push-in fittings are used with them, which must not be walled up. But if all the contours of the warm floor are made with solid pipe sections, then all connections will be only on the collector and it is quite possible to use PERT pipes.

In addition, manufacturers produce pipes of a composite structure, when aluminum foil is placed between two layers of cross-linked polyethylene, which is a reliable oxygen barrier. But the heterogeneity of the material, the difference in the coefficients of thermal expansion of aluminum and polyethylene can provoke pipe delamination. Therefore, it is better to choose PE-Xa or PERT pipes with a polyvinylethylene (EVOH) barrier, which significantly reduces the diffusion of oxygen into the coolant through the pipe wall. This barrier can be located in the outer layer of the pipe, or inside, surrounded by layers of PE-Xa or PERT. Of course, that pipe is better, in which EVOH layer located inside.

For underfloor heating circuits, there are three main pipe sizes: 16 * 2 mm, 17 * 2 mm and 20 * 2 mm. Most often, 16 * 2 and 20 * 2 mm are used. How to choose exactly the “right” pipe.

- Firstly, the brand in this matter matters and you need to pay attention to it. The most famous manufacturers: Rehau, Tece, KAN, Uponor, Valtec.

- Secondly, pipe marking can “tell” a lot, it should be carefully studied and you should not be shy to ask more questions to the sales assistant.

- Thirdly, the qualification of the sales assistant is very helpful when choosing a pipe. Do not forget to require certificates of conformity, inquire about the availability and price of fittings, mixing units, manifolds and other equipment. It is necessary to find out in which bays the pipe is sold, by how many meters, in order to take this into account in future calculations.

- And finally, if a PE-Xa pipe is chosen, then a small test can be carried out. To do this, a small section of the pipe must be broken, and then warm this place with a building hair dryer. High-quality PE-Xa, and PE-Xb pipes should also restore their original shape. If this does not happen, then whatever is written on the label is simply not a PEX pipe.

Underfloor heating design principles

One of the most important stages in the arrangement of warm water floors is their competent calculation. Of course, it is best to entrust this to specialists, but already enough accumulated experience suggests that this can be done on your own. On the Internet you can find a lot free programs and online calculators. Most well-known manufacturers provide their software for free.

water heated floor

First you need to decide on what temperature the warm floor should be.

- In residential areas where people spend most of their time standing, the floor temperature should be between 21 and 27°C. This temperature is the most comfortable for the feet.

- For working premises - offices, as well as living rooms, the temperature should be maintained around 29 ° C.

- In hallways, lobbies and corridors, the optimum temperature is 30°C.

- For bathrooms and pools, the floor temperature should be higher - about 31-33°C.

Heating with warm water floors is low-temperature, therefore, the coolant must be supplied at more low temperatures than in radiators. If water can be supplied to the radiators at a temperature of 80-90 ° C, then no more than 60 ° C can be supplied to the warm floor. In thermal engineering, there is such an important concept as temperature drop in the heating circuit . This is nothing but the difference in temperature between the supply pipe and the return pipe. In underfloor heating systems, 55/45°C, 50/40°C, 45/35°C and 40/30°C are considered optimal.

A very important indicator is (loops) of a warm water floor. Ideally, they should all be the same length, then there will be no problem with balancing, but in practice this is unlikely to be achieved, therefore it is accepted:

- For a pipe with a diameter of 16 mm, the maximum length is 70-90 m.

- For a pipe with a diameter of 17 mm - 90-100 m.

- For a pipe with a diameter of 20 mm - 120 m.

Moreover, it is desirable to focus not on the upper boundary, but on the lower one. It is better to divide the room into more loops than to try to achieve circulation with a more powerful pump. Naturally, all loops must be made with pipes of the same diameter.

Laying step (laying) of underfloor heating pipes - another important indicator, which is made from 100 mm to 600 mm, depending on the heat load on the warm floor, the purpose of the room, the length of the circuit and other indicators. Step less than 100mm do PEX pipes almost impossible, there is a high probability of simply breaking the pipe. If the underfloor heating will be equipped only for comfort or additional heating, then you can make a minimum step of 150 mm. So, what layout step should be applied?

- In rooms where there are external walls, so-called edge zones where the pipes are laid in increments of 100-150 mm. In this case, the number of rows of pipes in these zones should be 5-6.

- In the centers of the premises, as well as in those where there are no external walls, the laying step is 200-300 mm.

- Bathrooms, baths, paths near the pools are laid with a pipe with a pitch of 150 mm over the entire area.

Ways of laying the contours of the warm floor

The contours of a water-heated floor can be laid in different ways. And each method has its advantages and disadvantages. Let's consider them.

- Laying a pipe for underfloor heating "snake" easier to install, but its significant drawback is that there will be a noticeable temperature difference on the floor at the beginning of the circuit and at the end - up to 5-10 ° C. The coolant, passing from the supply manifold to the return one in the underfloor heating structure, cools down. Therefore, there is such a temperature gradient, well felt by the feet. It is justified to use this laying method in boundary areas where the floor temperature should decrease from outer wall to the center of the room.

- Laying a pipe for underfloor heating "snail" more difficult to implement, but with this method, the temperature of the entire floor will be approximately equal, since the supply and return pass inside each other, and the difference is leveled by a massive floor screed when the design requirements of the laying step are met. In 90% of cases, this method is used.

- Combined methods of laying underfloor heating pipes are also used very frequently. For example, the edge zones are laid with a snake, and the main area with a snail. This can help to correctly divide the room into contours, distribute the pipe bay with a minimum of residues and provide the desired mode.

Each method can be used variable paving pitch when in the edge zones it is 100-150 mm, and in the room itself 200-300 mm. Then it is possible to meet the requirements for more intense heating of the edge zones in one room without using other laying methods. Experienced installers often do just that.

Layout of the heating circuit with a "snail" with a constant step (left) and with a variable bare (right)

Layout of the heating circuit with a "snail" with a constant step (left) and with a variable bare (right) To calculate contours, it is best to use a special and very easy-to-learn software. For example, the well-known manufacturer Valtec, which distributes its program for free. There are also simpler programs for calculating the layout of the contours, which calculate the length of the loops, which is very convenient. For example, the program "Snail", which is also distributed free of charge. For those who are not very friendly with a computer, you can do the calculation of the contours on your own, using millimeter paper, on which you can draw a floor plan on a scale and “lay out” the contours on this sheet with a pencil and calculate their length.

When dividing the premises into contours of a water-heated floor, the following requirements must be met:

- The contours should not move from room to room - all rooms should be regulated separately. An exception may be bathrooms if they are located nearby. For example, a bathroom next to a toilet.

- One heating circuit must not heat a room larger than 40 m2. If necessary, the room is divided into several circuits. The maximum length of any side of the loop must not exceed 8 meters.

- Along the perimeter of the room, between rooms, as well as between individual circuits, a special damper tape should be laid, which, after pouring the screed, will compensate for its thermal expansion.

Choosing the type of insulation for underfloor heating and its thickness

Insulation for a warm water floor is mandatory, because no one would like to spend their money on heating the earth, the atmosphere or unnecessary building structures, but the floor is exactly the right one, which should take the lion's share of the heat from the heating circuit. For this, a heater is used. What types should be used? Among all their diversity, the authors of the article recommend that you should pay attention to only two of them.

- Extruded polystyrene foam (EPS). This material has low thermal conductivity and high mechanical strength. EPPS is not afraid of moisture, it practically does not absorb it. Its price is quite affordable. This insulation is produced in the form of plates of standard sizes 500 * 1000 mm or 600 * 1250 mm and a thickness of 20, 30, 50. 80 or 100 mm. For good joining of the plates on the side surfaces there are special grooves.

- Profile heat-insulating from expanded polystyrene of high density. On their surface there are special round or rectangular bosses, between which it is very convenient to lay the pipe without additional fixation. The pipe fastening pitch is usually 50 mm. This is very convenient during installation, but at a price they are much higher than XPS boards, especially from famous brands. They are produced with a thickness of 1 to 3 cm and dimensions of 500 * 1000 mm or 60 * 1200 mm - it depends on the manufacturer.

XPS boards can have an additional foil layer with additional markings. Marking the plates is, of course, useful, but the presence of foil only increases the cost of the insulation, and there will be no sense in it for two reasons.

- The reflectivity declared by the manufacturers will not work in an opaque medium, such as a screed.

- Cement slurry is a strong alkaline environment, which perfectly “eats” an insignificant (several tens of microns) aluminum layer even before it hardens. We must realize that foil plates are a marketing ploy and nothing more.

The authors of the article recommend using XPS boards for insulation. Savings compared to profile mats will be obvious. The difference in cost is enough for fasteners, and there is still a lot of money left. Let's remember folk wisdom that money saved is akin to earned money.

What thickness should be the insulation in the design of the warm water floor cake? There are special and complex calculations, but you can do without them. If you learn a few simple rules.

- If warm floors will be made on the ground, then the thickness of the insulation must be at least 100 mm. It is best to make two layers of 50 mm and lay them in mutually perpendicular directions.

- If warm floors are planned in rooms above the basement floor, then the thickness of the insulation is at least 50 mm.

- If warm floors are planned above rooms heated from below, then the thickness of the insulation is at least 30 mm.

Additionally, it is necessary to provide for the fastening of XPS boards to the base material, since when pouring the screed, they will tend to float. Dish-shaped dowels are ideal for this. They need to fasten all the plates at the joints and in the center.

To fasten the pipe to the EPS, special harpoon-brackets are used, which securely fix the pipe. They are fastened at intervals of 30-50 cm, and in the places where the PEX pipe turns, the pitch should be 10 cm. It is usually calculated that 500 pieces of harpoon-staples are required for a 200-meter pipe bay. When purchasing them, you do not have to chase the brand, as it will cost several times more. There are very high-quality and inexpensive staples of Russian manufacturers.

The choice of the collector-mixing node of the warm floor

The water floor collector is the most important element that receives the coolant from the main, distributes it along the circuits, regulates the flow and temperature, balances the circuit loops, and helps to remove air. Not a single warm water floor can do without it.

It is better to entrust the choice of a collector, and more correctly, a collector-mixing unit, to specialists who will select the necessary components. In principle, it can be assembled independently, but this is a topic for a separate article. Let's just list which elements should be included in order not to make a mistake in choosing.

- Firstly, these are the collectors themselves, which can be equipped with various fittings. They must be equipped with adjusting (balancing) valves with or without flow meters, which are located on the supply manifold, and on the return manifold there may be thermostatic valves or simply shut-off valves.

- Secondly, any collector for removing air from the system must be equipped with an automatic air vent.

- Thirdly, both the supply and return manifolds must have drain valves to drain the coolant from the manifold and remove air when the system is filled.

- Fourthly, fittings must be used to connect the pipe to the manifold, which are selected individually in each case.

- Fifthly, special brackets are used to fasten the collectors and ensure the required center distance.

- Sixthly, if the boiler room is not equipped with a separate riser for underfloor heating, then a mixing unit, including a pump, a thermostatic valve, a bypass, should be responsible for the preparation of the coolant. The design of this node has many implementations, so this issue will be discussed in a separate article.

- And, finally, the entire manifold-mixing unit should be located in a manifold cabinet, which is installed either in a niche or openly.

The collector-mixing unit is located in such a place that all the lengths of the lines from it to the underfloor heating loops are approximately equal and the main pipes are in close proximity. The collector cabinet is often hidden in a niche, then it can be placed not only in change houses and boiler rooms, but in dressing rooms, corridors and even living rooms.

Video: What calculations are needed before installing a warm floor

Do-it-yourself installation of a water-heated floor

After calculations and the purchase of all the necessary components, you can gradually implement a warm water floor. First, it is necessary to outline the places where manifold cabinets will be placed, hollow out, if necessary, niches, and also make passages through building structures. All grooving and drilling work must be completed before the next step.

Insulation installation

Before this stage, it is necessary to prepare the premises for this - take out everything unnecessary, remove all construction debris, sweep and vacuum the floors. The room must be absolutely clean. When installing the plates, wear flat-soled shoes, as heels can damage the surface. We list the sequence of actions during the installation of insulation.

- First of all, the level of the clean floor is beaten off on the walls with the help of laser or water. All the irregularities of the base are measured using a long rule and a level.

- If the irregularities exceed 10 mm, then they can be completely leveled with clean and dry sand, which should subsequently be leveled.

- If the underfloor heating is done on the ground or above the basement floor, then a waterproofing film is spread with an overlap of adjacent strips of at least 10 cm and with entry to the wall. The joints are sealed with adhesive tape. As a waterproofing, a polyethylene film of 150-200 microns is quite suitable.

- Starting from the far corner of the room, the process of laying XPS boards begins. They are laid close to the walls with the marked surface up.

- XPS boards must be tightly joined to each other using the grooves that are on their side surfaces. When laying each slab, it must fit snugly against the base and be in a horizontal plane, which is checked building level. If necessary, sand is poured under the slab.

- If along the laying path there are obstacles in the form of protrusions, columns and other elements, then after preliminary marking, the slab is cut with a construction knife along a metal ruler. In this case, the EPS must be placed on some kind of unstable base so that the knife does not become dull, for example, a piece of plywood or OSB.

- When laying the next row, it should be borne in mind that the joints of the plates should not coincide, but go apart, like brickwork. In order, if a part of at least 1/3 of its length remains with the remaining XPS slab in the row, then laying the next row should begin with it.

- If it is planned to lay the second layer of XPS, then it should be carried out in a mutually perpendicular direction with the first layer.

- After laying the thermal insulation, use a perforator with a long drill and a hammer to fix the dish-shaped dowels at each joint - at each joint and in the center of each XPS board. The joints between the EPPS are sealed with construction tape.

- If after the installation of the insulation there are cavities or cracks, then they can be clogged with EPS scraps and blown out mounting foam, but you can do this later, after the installation of pipes.

After that, we can say that the installation of insulation is completed. Although XPS boards are dense enough to support the weight of an adult, you still need to take precautions when moving on them. It is best to use wide boards or pieces of plywood or OSB.

Installation of a pipe of a warm water floor

The most crucial and difficult moment has come - the installation of floor heating pipes. At this stage, you need to be especially careful and accurate, and here you can’t do without an assistant. It is also desirable to have a special device for unwinding the pipe, since it is strictly forbidden to remove the pipe from the coil with rings, since then there will be very strong stresses in it, which will complicate or make installation impossible. The main rule is that the coil must be twisted, and not removed from the fixed coil. In principle, this can be done manually, but with a device it is much easier.

If there are markings on the upper side of the XPS boards, then this is just great, then pipe laying will be greatly simplified. And if not, then you should not “be led” to purchase a thin foil insulation made of polyethylene foam with applied markings. There will be no sense from him. You can also mark up yourself. To do this, marks are made on the upper side of the plates with a marker at the distance of the required contour step, and then lines are beaten off with a paint thread - this way you can make markings in a short time. After that, you can draw the paths of the contours of the warm floor.

screed for underfloor heating

In the intended place, a collector cabinet is attached and a collector is mounted in it, while without a pumping and mixing group, it will be needed later. At the entrance to the collector, at the exit from it, as well as at the entrance to, each pipe must be protected by a special corrugation. However, corrugation from eminent manufacturers costs mind-boggling money, so it is quite acceptable to replace it with thermal insulation of the appropriate diameter. Pipes must also be protected when passing from room to room and from circuit to circuit.

Installation of the underfloor heating pipe should be started from the areas most remote from the collectors, and all transit pipes should be insulated with polyethylene foam, which will ensure maximum energy conservation to the destination point and will not “lose” heat along the way. Further, the pipe “emerges” from the EPS boards, already “naked” bypasses its entire heating circuit and “dives” back and already in thermal insulation follows to the collector. The transit pipes themselves are placed inside the XPS slabs; for this, passage routes are pre-cut into them with a knife.

If the thermal insulation consists of two layers of XPS boards, then the first layer is laid first, then all communications are laid, including the transit pipes of the underfloor heating, and then the second layer is adjusted and cut on the spot.

In addition, pipes to radiators, as well as hot and cold water supply lines, can go in the area of \u200b\u200bthe warm floor. If there are several pipes, then they can be fixed in a bundle either with dish-shaped dowels, or with a perforated metal strip and dowels. In any case, they should not protrude beyond the upper surface of the XPS boards, so that the contour of the warm floor can be easily laid from above. All cavities are blown out with mounting foam, which, after hardening, is cut flush from the surface of the insulation boards.

Along the perimeter of the room where there will be warm floors, a damper tape is glued to the walls, which is designed to compensate for the thermal expansion of the screed. Tape comes with or without adhesive. When acquiring it, you do not have to chase the brand and overpay several times more. Now a worthy damper tape is being produced in every sense Russian production. If there is no tape at all, then this is also not a problem - it can be replaced by foam plastic 1 or 2 cm thick, glued to the wall with liquid nails or mounting foam.

The damper tape must also be installed between rooms and different circuits. For this, it is issued special tape with a T-shaped profile. And in this case, it can be replaced by thin foam glued with mounting foam or glue.

Pipe installation is done as follows:

- 10-15 m of pipe is unwound from the coil, thermal insulation and a corresponding fitting are put on its end for connection to the collector.

- The pipe is connected to the supply of the corresponding outlet of the collector.

- A pipe is laid along the previously marked routes and fastened with harpoon-brackets in straight sections after 30-40 cm, and on turns after 10-15 cm. The pipe should be bent carefully, without creases.

- When laying, do not try to fasten the pipe immediately, but you should first lay it out approximately along the tracks for 5-10 m, and only then fasten it with brackets. The pipe should lie on the insulation without tension, there should be no effort that tries to pull the staples out of the EPS.

- If for some reason the bracket flew out of its place, then it is mounted in another, at a distance of at least 5 cm.

- After bypassing the entire circuit of the warm floor, the return pipe returns to its supply pipe and follows it next to the collector. If necessary, thermal insulation is put on it.

- Upon arrival at the collector, the pipe is connected to it with an appropriate fitting.

- Near the corresponding loop of the warm floor on the wall, as well as on paper, the length of the contour is necessarily recorded. This data is necessary for further balancing.

All contours are laid in the same way. At first it will be difficult, but then, after one laid “snail”, everything will already be clear and the work will go without problems. When moving along already laid contours, it is necessary to lay boards, plywood or OSB under the legs or knees.

Walking in shoes through pipes is not recommended. It is better to organize such "paths"

Walking in shoes through pipes is not recommended. It is better to organize such "paths" Video: Laying a floor heating pipe

Reinforcing mesh installation

Disputes about the appropriateness of reinforcing mesh are ongoing. Someone says that it is needed, others say the opposite. There are many examples of successful implementation of underfloor heating without reinforcing mesh and, at the same time, there are examples of unsuccessful implementation of underfloor heating with reinforcement. The authors of the article argue that reinforcement will never be superfluous, but only correctly performed.

The Internet is replete with examples when a metal mesh is laid and fixed on the insulation, and only then a warm floor pipe is attached to it with plastic ties. It seems to be convenient, but this is not reinforcement, but simply putting an absolutely useless mesh under the screed, on which money was spent. Reinforcement is when the mesh is inside the screed, and not under it. That is why the authors recommend placing the grid on top of the pipe.

For reinforcing the screed, a metal mesh made of wire with a diameter of 3 mm with a cell size of 100 * 100 mm is suitable - this is quite enough. It is not recommended to use reinforcement meshes due to the fact that the reinforcement has a corrugated surface and during installation can damage the smooth surface of the pipe. Yes, and you should not spend extra money on excessive strength of the screed, because it is assumed that the warm floor is already mounted on a fairly solid foundation. The mesh is laid with an overlap on one cell and is connected either with a knitting wire or plastic clamps. Sharp protruding ends must be bitten off so that they do not damage the pipe. Additionally, the mesh is attached to the pipe in several places with plastic clamps.

Instead of a metal mesh, a plastic mesh may well be used, which will perfectly reinforce the screed and save it from cracking. It is more convenient to lay a plastic mesh, as it comes in rolls. Application plastic mesh virtually eliminates damage to pipes, and its cost is significantly lower.

After laying the mesh, the question of protecting the pipes again arises, because, moving in shoes along metal mesh, you can easily damage both it and the pipe. Therefore, it is again recommended to move only on boards, plywood or OSB. But there is still a very competent solution that will avoid damage to the pipes when pouring the screed.

A cement mortar is prepared - the same as it will be when laying the screed (1 part of M400 cement and 3 parts of sand) and during the laying process, “blobs” are made from the mortar, which protrude slightly beyond the surface of the mesh - 2 cm is enough. These "blobs" are made at such intervals (30-50 cm), which will allow you to put boards or plywood on them in the future and move completely safely. Another plus of this approach is the fixation of the mesh, because when walking on it, it tends to bend, and this can damage the welds.

"Foots" from the solution will fix the grid and help you move safely

"Foots" from the solution will fix the grid and help you move safely Filling in contours. Hydraulic tests

This operation should definitely be carried out even before the screed is poured, since with a hidden malfunction it is easier to fix it immediately than after the floors are filled. To do this, a hose is connected to the drain pipe on the collector and discharged into the sewer, since a lot of water will be spilled through the heating circuits. It is best if the hose is transparent - it will be easy to track the exit of air bubbles.

To the inlet of the supply manifold, which must be equipped with a shut-off ball valve, is connected tap water through a hose or pipe. If the quality of tap water is low, then it is worth filling the system through a mechanical filter. A pressure test pump is connected to any other output connected to the underfloor heating circuits. This may be a free outlet of the supply manifold, a return outlet from the manifold and other places - it all depends on the specific implementation of the collector unit. In the end, a tee can be screwed into the ball shut-off valve of the supply manifold and both filling the system and pressure testing can be done through it. After testing, the tee can be removed and the manifold connected to the supply line.

Filling the system is done as follows:

- On the collector, all the contours of the warm floor are blocked, except for one. Automatic air vents must be open.

- Water is supplied and its purity and air outlet are controlled through the drain hose. Process grease and chips may remain on the inner surface of the pipes during production, which must be washed off with running water.

- After all the air has escaped and the water flows absolutely clean, the drain valve is closed, and then the already washed and filled circuit is closed.

- All these operations are done with all contours.

- After flushing, removing air and filling all circuits, the water supply valve is closed.

If leaks are detected even at the filling stage, they are eliminated immediately after the pressure is released. As a result, you should get a system of warm water floors filled with a clean coolant and airless.

To test the system, you will need a special tool - a pressure test pump, which can be rented or invited by an experienced craftsman who has such a device. Let us describe the sequence of actions during crimping.