Assembly of the drainage system. How to properly install roof gutters. Prices for a hacksaw for metal

Such an important architectural element of the roof structure, which is the drainage system, must be thought out at the design stage. Moreover, modern SNiP recommend installing the system even before installing the roof covering. However, in reality, not everything is so smooth.

Sometimes circumstances force you to install a gutter system if the roof is already ready. Accordingly, it will not be superfluous to learn how to install gutters if the roof is already covered.

In what cases the drain is installed during finishing work

There are several situations when such an installation is necessary:

You can also try another option for fixing the hooks to the rafters. The brackets are fixed to the side edge of the rafter. The mounting surface of the holders is bent into a plane horizontally (this operation can also be performed independently). This type of installation is possible only when the cross section of the rafters is large enough, for example, 12 or 15 * 5 cm. When fixing the brackets, it is important to take into account that the roof covering should cover the gutter by half or a third of its width. Then you can not be afraid that as a result of heavy precipitation, water will overflow over the edges of the gutter.

Obviously, when mounting the brackets on the side face of the rafter, a preliminary fitting is required. In the process of fitting, it will just become clear whether such an installation option is possible.

Frontal board - a solid foundation

For those who are wondering how, if the roof is already covered, it is important to know that the simplest option installations - frontal board.

On a note

It can be easily decorated, and the board will look like an independent detail of the roof exterior.

- Long holders are used if the wind board has a sufficiently large width. Such brackets are made of metal, and the leg of the holder and the hook have the same width. Fixation to the board is carried out through the holes provided on the mounting platform, which is located on the leg.

- Short brackets can be used not only when mounting on a windboard, like long ones, but also walls and rafter ends. True, at the same time, the reliability of the fastening is questionable, since the fasteners are located along the wood fibers.

Pick up short hooks made of the same material. It is also desirable to fix them on metal. Light weight allows you to fix them to a wooden windboard without any difficulties.

Special mention is made of adjustable brackets equipped with a special device. It shifts one part of the bracket relative to the other, setting the slope of the holder location, that is, the angle that forms the hook and the base for the fasteners. To get the desired angle, just tighten the adjustment screws. Such brackets are almost indispensable for use in difficult conditions, for example, if the windboard is tilted.

- When installing individual holders, to begin with, a straight line is beaten off on the windboard, observing the slope within three to five mm / linear. m. in the direction of the drain funnel. Stepping back from the edge of the end part of the wind board (the indent is approximately 50 - 100 mm), mark the place of fixation of the first bracket. After that, on the entire line, the installation locations of the holders are marked with a step of no more than 0.6 m (in some cases, even a larger step is acceptable, which is necessarily noted in the instructions). Having completed the markup, proceed to the installation of brackets.

- A sufficient width of the roof overhang allows the use of another, very convenient option for installing gutters. Special short holders are fixed on a common metal guide profile. The latter, in turn, is fixed either on the wall of the house or on the wind board through the special holes provided on it. When fastening, the guide is immediately given the required slope. Thus, when installing the holders, there is no need to measure their place in height.

After that, brackets are threaded from its side and advanced along the guide, placing them with the required step. It is noteworthy that such holders do not need to be fixed, since they “sit” quite firmly in the profile. Undoubtedly, this is another advantage of such a mounting system.

"Crutches" as a basis

Sometimes there is no wind board in the roof structure at all. Then they resort to the help of special "crutches" made of metal or wood, fixed in the wall. The gutters are attached directly to the "crutches" on studs or bars.

Fastening on the edge of the roof

This method is justified when fixing the drainage system from the roofs along its eaves. This option is suitable for almost any roofing material. The brackets are fastened using clamps (as special clamps are called).

If the system is fixed to the wave material, then the holders are attached either to the lower or the upper point of its wave. At the same time, it is desirable to lay rubber gaskets under the legs of the metal clamps on both sides of the roofing sheet. Thus, two tasks can be solved at once: slightly reduce the load and soften the compression on the sheet.

Additional brackets

When using the above option for installing gutters, you can also use short hooks, but with one condition. In addition to them, L-shaped metal brackets are needed. Their long part is fixed on the side edge of the rafter. As for the curved shelf with a mounting platform on short parts, a short PVC holder is fixed on it. It is worth noting that in some cases this is the only way to fix the holders on the previously laid roof without damaging it. For example, if the roof protrudes beyond the ends of the rafters on the cornice overhang of about 12–15 cm.

invisible brackets

The construction market also offers brackets that hold the gutter from above, in contrast to the traditional version from below. They are completely invisible once installed. Such holders are mounted at a distance of 400 - 700 mm between them. If this condition is violated, there is a high probability of significant deformation of the gutter, caused by the impact of a significant load of the gravity of ice or snow.

Brackets that are used when installing to the crate, or from above to the rafters, must first be bent. The holder is thus given the desired shape, which subsequently allows it to be perfectly adjusted to the slope of the ramp.

Pull-up mount

Hanging mount is less popular than the above options. However, in some cases, such a construction is the only possible way. This type of bracket has special bends. During installation, one of them is put on the front edge of the gutter, while the second is hooked to the back. The holder is equipped with a sleeve having internal thread. The fastener is screwed into the wall or windboard through the bushing and the upper section of the gutter wall.

How to install roof gutters : other possible ways

- Mansard-type roof brackets can be fixed directly to the walls after careful measurements and subsequent marking.

- On a filing of soffits of the required width, the brackets are fixed to L-shaped metal profiles, which are screwed to the sheathing of soffits.

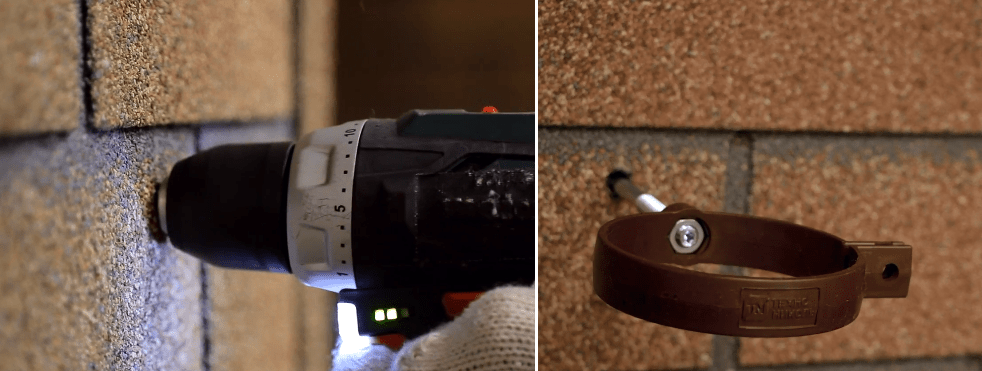

- In the absence of a frontal board, or if the soffit is narrow enough, special metal pins with a pointed end are used. They can be straight or L-shaped. In the wall brickwork or from concrete, a hole of a suitable diameter is pre-drilled and filled with a solution of concrete, then a pin is driven in. After the mortar has completely set, installation of the gutters can begin.

On a note

When marking the location of the pins, it must be ensured required slope in the direction of the funnel of the drainage system.

One of the key stages in the arrangement of the roofing system of the house is drainage. Without its organization, it is impossible to protect the facade of the building from rain and water flows during the snowmelt period.

How to properly install gutters and what to consider when installing the structure, we will consider in the article.

The question of how the drainage system will be equipped should be decided at the design stage of the building.

When making calculations, you need to be guided by the requirements of the current SNiPa 2.04.01-85. This approach will allow, taking into account all the nuances, to correctly select best option construction execution.

Key purpose drainage system– collect and remove precipitation, thereby protecting the walls and foundation of the building from premature destruction

The main points to be followed when designing a drainage system:

- Having made a copy of the roof drawing, draw a plan for the location of the drainage elements.

- Calculate the total area of the roof and all its slopes separately, taking into account the adjacent vertical walls.

- Based on the indications of the intensity of rains in a given area, determine the throughput of the system.

- In accordance with the values obtained, determine the diameter of the installed drainpipes, the number and cross section of drain funnels, as well as the frequency of their placement along the wall of the building.

The result should be a system that can collect and remove the maximum amount of liquid.

At the design stage, it is important to determine the location of the risers so that they do not disturb the exterior composition. Most often they are placed at the corners of the building, but it is quite possible to arrange it in a niche created by a bay window.

If the discharge of the pipe coming from the drains will be carried out on the blind area, it is better to remove the risers as much as possible from the entrances to the basement, basement ventilation vents and footpaths laid near the house.

Components of the drainage system

The system includes two groups of parts - horizontal and vertical drainage parts. Together they number about a dozen types of structural elements, each of which performs the task assigned to it.

The main thing when choosing the components of the drainage system is to select elements that are both structurally and according to appearance harmoniously complement the overall picture

The structural elements of the drainage system are:

- drainpipes- key functional elements of the system, designed to move masses of water from the roof;

- gutters– narrow channels for collecting and redirecting water;

- funnels- conical sockets in the upper part of the pipe are designed to collect, delay and drain water flowing down the gutters;

- knee- structures in the form of short bent pipe sections are installed in order to change the direction of the water flow;

- brackets- fasteners for fixing the gutter to the roof;

- seals- additional elements provide fastening strength at the joints;

- clamps- fasteners for fixing the structure to the facade of the building.

Calculation of the required number of elements

It is better to entrust this rather important event to specialists selling drainage systems, or to the masters of the company providing installation roofing services. In the absence of such an opportunity, the calculation can be performed on its own.

Since in private construction many people try to get away from typical options and roofs similar in design, the required number of system elements should be calculated individually.

The main points of competent calculation:

- gutters. The total length of the channels must correspond to the length of all roof slopes used to collect water. Their docking is carried out using connectors.

- Water receiving funnels . They are installed at the outer corners of the building and additionally placed every 8-12 meters so that the overall slope of the channels is not too large.

- Downspouts. The number of products corresponds to the number of funnels, and the length corresponds to the distance from the roof to the surface of the earth.

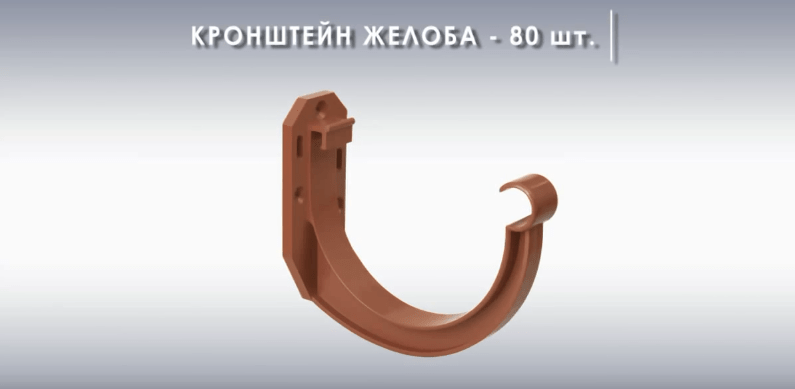

- brackets. The number of brackets is determined on the basis that one element is required for each meter of the channel. Additional holders will be required for funnels in the center and wall and in the corner of the house.

The number of clamps directly depends on the height of the building. But in any case, each individual pipe section to be installed is fixed with at least one clamp. When installing a downpipe in a one-story building, three fasteners are often enough, located at the top, bottom and in the middle of the product.

When calculating, the condition is taken as a basis that for 1 sq.m of the roof in horizontal projection there should be 1.5 sq.cm of the cross-sectional area of \u200b\u200bthe drain and funnel. For example: the sectional area of a pipe D 100 mm is 78.5 sq.cm. This is an average value.

Depending on whether it is necessary to install the system in regions with a high level of precipitation, or, on the contrary, in arid areas, amendments are made to the calculations.

Bracket mounting methods

Installing brackets according to the rules is still at the stage preceding the laying of the roof. If fixation is carried out after the coating has been laid, then ordinary short hooks are used as fasteners.

Image gallery

Short brackets are attached to the front board so that they create a slope towards the funnel. We calculate how much lower the hook at the funnel should be than the highest holder. We mark the position of the extreme brackets on the board

We fasten the two extreme holders: the highest and the lowest, located next to the funnel. We connect them with fishing line or lace

We check with the building level whether the slope is created by hooks and whether its value meets the conditions specified by the manufacturer of the drainage system

We mark on the frontal board the attachment points of ordinary hooks. There should be an equal distance between them, the height is determined by the stretched lace. We fix short brackets with self-tapping screws

Step 1: Fitting the short hook to the installation site

Step 2: Attaching the highest holder

Step 3: Checking the slope formed by the holders

Step 4: Fixing the ordinary drain holders

Depending on the shape of the bracket, the elements can be fixed in one of three ways:

- Fixing to the frontal roof board- it is used when it is necessary to install the system on a finished roof.

- Rafter leg attachment- used at the installation stage prior to laying the roofing material.

- Fixation on the bottom edge flooring or the first lath of the crate is used for roofing, the step between the rafters of which exceeds the mark of 600 mm.

Brackets designed for fixing to the frontal roofing board are most often included in the package of systems made of polyvinyl chloride.

Suspended structures for fixing to the frontal board have reinforced vertical ribs, due to which they can easily withstand heavy loads

Metal brackets for fastening to the frontal roofing board are made shorter. If the roof structure does not provide for a frontal board, combined brackets are used.

They are equipped with extensions made of steel. Due to this, it is convenient to mount them directly on the rafter leg.

Image gallery

Numbers are put on the legs of long brackets and a fold line is marked, which should ensure the slope of the gutter

According to the markup, the brackets are bent. The work is done with the help of a special tool.

In accordance with the numbering, the brackets are laid out along the crate

First, two extreme brackets are installed, between which the cord is pulled. This line is needed for a landmark that determines the slope

Step 1: Slope the Long Brackets

Step 2: Bending the Long Metal Brackets

Step 3: Layout of the bent brackets along the slope

Step 4: Marking the line for attaching the holders

In case it is impossible to provide access to the rafters, metal crutches are attached to the wall. They act as a support for further fastening of the metal gutter.

The method of fixation, which involves mounting on a rafter leg, is effective in arranging roofs of houses in regions with heavy rainfall. It is also used, if necessary, to drain water from roofs with a large area, for which heavy coatings are used.

When fastening to the rafter leg, to increase the reliability between the fasteners, they maintain an equidistant distance equal to 50 centimeters

With this method, the hooks are led behind the base and set at an equidistant distance in order to provide the desired slope of the gutter.

The third method of fixation, which involves fastening to the crate, is most often used when arranging a roof that has a coating of ondulin or metal tiles. It is chosen only if the recesses cannot reduce the bearing capacity of the crate in the cornice area.

For fixing on the counter rails of the crate, combined models of brackets or metal long hooks are used, deepening them into the long grooves of the mounting strips

When choosing the third method of fixation, it is important to remember that only strict adherence to the installation rules and the installation procedure can ensure the reliability and durability of the structure.

Gutter installation technology

Installation of equipment for gutters is carried out after the completion of facing work. There is nothing difficult in how to prepare and install a drain. PVC installation systems can be performed even by a novice master.

The assembly and installation of a drainage system includes a number of standard steps:

Image gallery

Ideally, the gutter system is installed before the roof is laid. But in the case of a piece coating, you can remove the bottom row of tiles and carry out work

Before mounting the brackets, we select the optimal position of the outer holders. They should provide a slope towards the drain funnel, the width of the gutter should protrude 1/3 beyond the edge of the cornice

According to the mark, we bend the legs of the two extreme brackets located at the highest and lowest points of the gutter

After installing the two extreme brackets, we connect them by pulling a fishing line or twine. This line is needed for accurate marking of ordinary holders

We check the building levels for the slope created by the holders

The edges of the gutter, located near the corner of the slopes, are closed with plugs to prevent water from flowing past the funnel

If the length of the slope to be equipped is more than 3 meters, then we build up the gutters using a connector that compensates for linear expansion

We fix the gutters installed on the brackets by bending the tab of the holder

Step 1: Installing an additional slat

Step 2: Trying on the bracket to determine the fold line

Step 3: Installing the end holder for the gutter

Step 4: Marking the installation of row brackets

Step 56 Checking the correct slope

Step 6: Installing the end cap on the edge of the gutter

Step 7: Joining the Gutter Pieces

Step 8: Fixing the gutter with the tongue of the bracket

After installing and fixing the gutters, drainage funnels are installed at the lowest points of the drainage system, to which drainpipes are connected:

Image gallery

We remove the part of the gutter to which the catchment funnel and riser will be connected. We apply a funnel to mark a hole through it, which we will cut in the gutter

In the place marked on the gutter, we drill a hole with a diameter corresponding to the diameter of the downpipe

On the bottom side of the gutter, we apply a catchment funnel and fix it by snapping the edges on the edge of the gutter

We return the chute with the funnel to its place. We connect two knees to the drainage funnel to bring the main part of the pipe closer to the wall

Step 9: Marking out the location of the funnel

Step 10: Drilling a Hole in the Gutter

Step 11: Attaching the Funnel to the Gutter

Step 12: Connecting Downpipe to Funnel

Installation of horizontal elements

A set of tools that will be needed during the work:

- marking cord;

- tape measure at least 3 meters long;

- hacksaw for metal;

- universal screwdriver;

- a hammer;

- flat bender;

- pipe pliers.

Some craftsmen cut metal gutters and pipes using a grinder. But this is far from the best solution, since the rotating disk heats up the polymer coating during operation. And this can cause damage to the elements of the drain during operation.

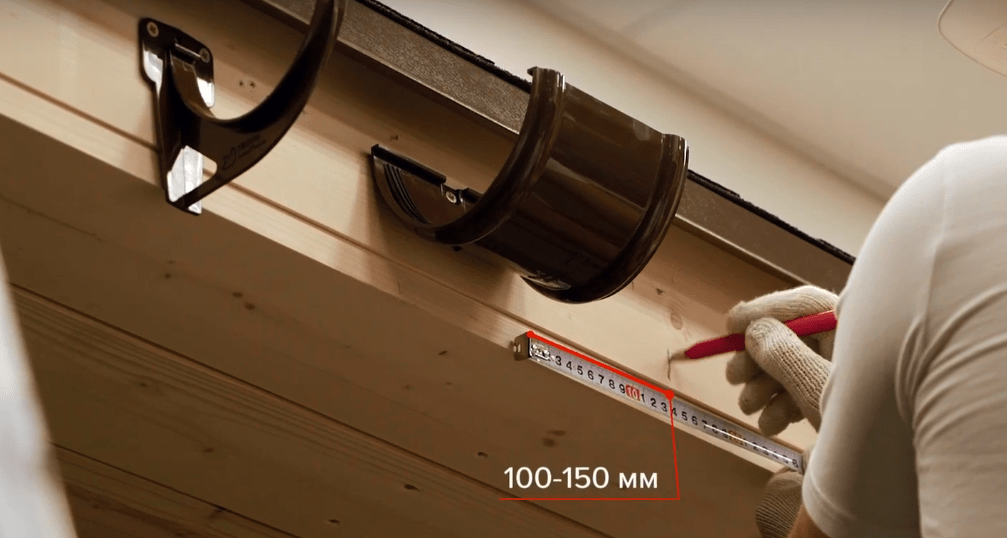

The first step is to mount the brackets that are designed to support the catchment funnels, placing them at a distance of 5-10 cm from the elements

The installation of brackets begins with the installation of the extreme elements. Then the distance between the drainpipes is divided into equal intervals of 60-80 cm long for the installation of the remaining hooks.

To simplify your task by ensuring a uniform slope of the gutters in the direction of the water intake funnels, it is better to pull the cord when marking. The boundary values of the slope are from 2 to 5 mm per linear meter. To improve the accuracy of the installation, it is better to mark several key lines by pulling the cord in two or three rows for this.

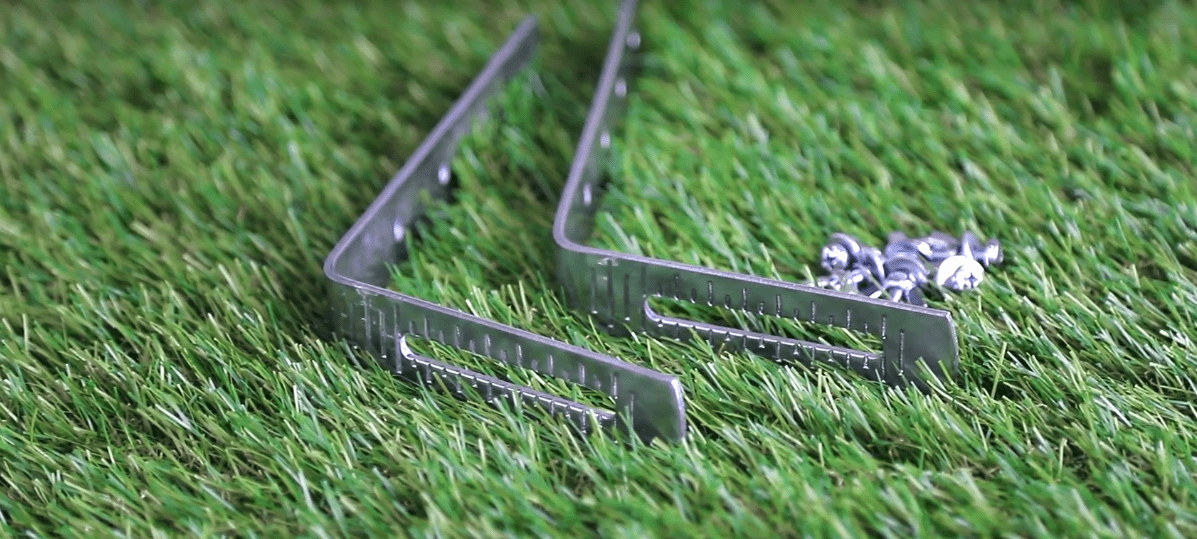

If you have to work with metal hook-brackets, before attaching, they must be bent in accordance with the angle of the roof

In the process of mounting the brackets, the slope is achieved by moving the short fasteners vertically or by bending the metal holders in the calculated place.

In order not to disturb the galvanization and not damage the polymer coating, a special device is used to bend the fasteners - a flat bender.

The brackets are fixed on the mounting plate at three points, using self-tapping galvanized screws for this, not forgetting to correct the deviation from the direction given by the cord along the way

The collection of the drainage system can be done in one of two ways:

- Lay out all the elements on the ground in a horizontal position, and then insert assembled structure into brackets fixed around the perimeter of the building. This method is applicable for small houses and small finishing areas.

- The traditional option involves the phased assembly of all elements of the system directly on the building.

Installation of the drain should be carried out in the order "from top to bottom": first, water inlets are installed, then drain risers are connected. It's dictated technological features drainage system.

With the traditional stage-by-stage assembly of all elements of the drainage system, the installation of the structure is carried out strictly on the principle of "top down"

Before attaching the gutters to the parts of the roof, the funnels are first mounted, not forgetting to take into account possible thermal expansions. Then the gutters are installed, placing them 2 cm below the line, which conditionally acts as a continuation of the overhang. They are produced in lengths of 3-4 meters. Gutters that occupy the extreme positions in the line will most likely need to be cut.

When installing gutters, it is worth remembering that they must be at least a third covered by the overhang of the eaves. Ideally, the overlap should be half of its own diameter.

The gutter is placed in the holders in a slightly bent state, leading into the grooves of the hooks, first its far side, and then the near one, and fixing it by snapping

Installation of a drainage system is relevant even for small baths.

The rationale for this is very logical and simple:

- if there are no drainage gutters, then during precipitation, moisture flows freely from the roof directly onto the walls of the bath. Along with rainwater, accumulated dust, dirt, and small debris also flow down. As a result: dirty walls, windows and front door. In such conditions, the appearance quickly deteriorates and the service life of wood, plaster, brick and any other materials decreases;

- moisture flowing from the roof is collected directly near the foundation or blind area, if any. And the more it rains, the more the soil becomes saturated with water. As a result, subsidence of the blind area and even the foundation may occur. In addition, if the foundation is not adequately waterproofed, moisture will seep into the subfloor, having a negative impact on the floors of the first floor and the microclimate in the premises.

On a note! SNiP 31-06 of 2009 regulates the issues of drainage from the roof. So, according to regulations, in private construction it is permissible to have no drainage systems on the roofs of one- and two-story buildings, but on condition that over entrance group and the balcony has canopies, and the cornice overhang is wider than sixty centimeters.

Any bath with an installed drainage system looks more aesthetically pleasing and solid, the appearance is complete and solid. Yes, and the benefits of installing gutters are palpable.

It is advisable to engage in the installation of hooks and gutters even at the stage of construction of the roof of the bath, but even after the completion of the construction and exterior finish It's not too late to start plumbing.

And the first stage of the forthcoming work is the choice of a drain and the calculation of the number of elements.

On sale you can find a drainage system for every taste and budget. From the point of view of efficiency, plastic (polyvinyl chloride or vinyl) gutters are in the first place, and elite copper and zinc-titanium products close the list. Steel, aluminum systems belong to the middle price category. But focusing only on the price tag is not always correct, you should pay attention to the service life of products and ease of installation. But the noiselessness of drains can only play a role in one case - if there are living quarters in the bathhouse or the building is attached to the main house, but usually the sound of rain through gutters and pipes rarely bothers those who visit the steam room.

Table 1. Varieties of external drainage systems according to the material of manufacture

| Production material | Peculiarities | For which roofs is recommended |

|---|---|---|

| Wall thickness up to 3.3 mm. The color palette of plastic gutters is rich, but after a few years of operation, the shade may lose saturation. It is very easy to mount a plastic drain on a roof of absolutely any configuration thanks to a large selection of additional and fasteners. And the low weight of the products and the lack of the need to use special tools is an additional plus for those who want to do the installation themselves. It can last up to 30 years, but it is better to choose quality products. with a wall thickness of 3.3 mm. | Well in harmony with the roof of ondulin, slate, soft bituminous tiles. | |

| Classical gutters with a service life of 60 years or more. They are made from rolled products up to 0.7 mm thick. Do not burst, do not break, do not spoil the appearance of the bath. Relevant for regions with predominantly sunny weather, scorching sun. Among the shortcomings: firstly, certain difficulties may arise during the installation process, and secondly, not all truss systems are designed for the weight of a metal drain. | Metal galvanized roofing. | |

| Relate to metal gutters. A layer of primer and a polymeric protective coating, such as pural, polyester, modified polyester or plastisol, is applied over the steel base. The service life is impressive, but can be reduced if the decorative coating is damaged (the corrosion process begins actively). All coatings are resistant to the action of sunlight, except for polyester, which quickly loses the saturation of the shade. | Decking, metal tile with polymeric coatings. | |

| Wall thickness up to 0.8 mm. Lightweight, strong, reliable. Not subject to corrosion. Wide choice of shades. | Any metal roof. | |

| They are made from a material with a thickness of 0.7-0.8 mm. Not subject to corrosion, not afraid of UV radiation and high temperatures. Scratches on the surface can heal on their own. The service life reaches one hundred years. Disadvantages: incompatibility with some metals and high price. | Suitable for elite roofing such as seam copper, slate, natural ceramic or composite tiles, shingles, titanium-zinc. | |

| Copper drains have a thickness of not more than 0.6 mm. Elite drains are valued for their durability (up to 150 years, subject to proper installation). They do not need to be touched up, often cleaned or maintained. Copper drains do not care about the heat and high humidity. They don't fade or rust. The average price of one three-meter trough made of copper is 6 thousand rubles, one three-meter section of the pipe costs about the same, and the prices for receiving funnels reach 15 thousand rubles. To equip an expensive drainage system for a bath on suburban area unreasonable, another thing - a prestigious bath complex with a height of several floors. | Ceramic tiles, slate tiles, copper sheet roofing or flexible copper tiles. |

Table 2. Dependence of pipe diameter on roof area

Table 3. Dependence of the width of the trays on the number of risers and roof area

| Roof area, sq.m | Number of risers | Gutter width, cm |

|---|---|---|

| Up to 70 | 9 | |

| 70 to 140 | 13 | |

| Up to 110 | 9 | |

| 110 - 200 | 13 | |

| No more than 140 | 9 | |

| 140 to 220 | 13 |

Calculation of the number of elements

To calculate the number of elements, you need to schematically draw a sketch of the bath, take measurements of the building, and then put them on the picture. This will make the calculation process as easy as possible. Then, on the same diagram, you can draw a draft drainage system indicating the elements.

Table 4. Elements of gutters

| Name | Description |

|---|---|

| The total length of the gutters corresponds to the length of the eaves minus the length of the corner pieces, if provided. The standard length of 1 gutter is usually 3 meters. | |

| They are counted by the number of joints of the gutters. | |

| 2 plugs per open gutter line. If the drain is closed around the entire perimeter of the roof, plugs are not needed. | |

| Prevents the accumulation of large debris in the gutters. The length corresponds to the total length of the gutters. | |

| The quantity depends on the configuration of the roof and the length of the eaves (L). If L is 12 meters, then the funnel is installed closer to the center of the eaves or two funnels are placed at the corners of the roof. In accordance with SNiP II-26-76, the distance between funnels cannot be more than 26 meters. | |

| In count internal corners baths. Usually the length of the corner is 40 cm. | |

| Accordingly, by the number of external corners. Elements can be 90 and 135 degrees. | |

| The step between the brackets depends on the material from which the drain is made. For plastic systems pitch 55-60 cm, metal - 70 cm, copper - 30-60 cm. The smaller the pitch between the hooks, the greater the load the gutters can withstand. The number of hooks is equal to the total length of the cornice divided by the pitch between the hooks. From the edge of the eaves, the hooks are fixed at a distance of 15 cm. Additional hooks (2 pcs.) Are installed on both sides of the gutter connectors. |

|

| The standard length of one pipe is 3 meters. The total length of the riser corresponds to the height of the bath wall. | |

| If necessary, for connecting pipes in a riser with a height of more than 4 meters. | |

| If necessary, for each riser. The size of the knees depends on the size of the cornice overhang. | |

| If necessary, connecting risers, combining pipes. | |

| By the number of risers, subject to availability storm sewer. | |

| If there is a storm drain. | |

| It is installed 15 cm from the ground if there is a drain collector (well) or 30 cm from the ground if there is no well. | |

| The step between the holders is not more than two meters. The length of the screw with the dowel is selected depending on whether the facade is insulated or not. |

Gutter prices

gutter

An example of the calculation of the drainage system

Initial data: four-pitched roof. The length of the cornice along the long side of the bath is 12 m, along the short side - 8 m. The cornice overhang is 0.9 m. The height from the cornice to the ground is 8 m. m.

The roof area is more than 100 sq.m, so we choose gutters and pipes with a cross section of 130 mm. The facade is insulated, the thickness of the insulation is 50 cm. We choose screws 160 mm long. Retraction - knee 67 degrees.

Cornice length:

8 + 8 + 12 + 12 = 40 meters.

Number of gutters:

40 m: 3 m = 13.3 pcs.

Rounding 13.3 up to the larger integer 14.

Number of drainpipes:

8 m (length from the eaves to the ground) x 4 (number of risers) = 32 m.

32 m: 3 m (length of one pipe) = 10.66 (round up to 11 pieces).

Two more pipes will be needed to bring the drain to the wall.

Total: 13 pipes.

Number of brackets and extensions. From the edge of the funnel, the bracket is fixed at a distance of 10 cm, the step between the hooks is 55 cm. In total, 80 brackets are needed.

If the hooks are attached to the frontal board, you will need 80 x 3 = 240 self-tapping screws.

If there is no frontal board, you will need bracket extensions (straight or twisted).

Straight lines are attached to the flat part of the truss system.

Twisted extensions are attached to the side of the rafters.

With the help of the same extension cords, if there is no frontal board, couplings and funnels are attached. In this case, the number of extensions is equal to the number of brackets + the number of couplings + the number of funnels. A total of 94 extension cords will be needed.

Bracket extension prices

bracket extension

Number of two-socket outlets: 8 pieces. Each funnel has 2 outlets.

4 funnels x 2 outlets = 8 outlets.

Scheme of connecting a funnel with a drainpipe with two-socket bends and a pipe segment

Number of brackets: 28 pieces. They are installed under each connecting element. The step between the brackets is assumed to be 1.5 m.

Outcome:

- the required number of funnels - 4 pieces;

- the same number of outer corners of the gutter;

- number of gutters (L = 3 m) - 14 pieces;

- 10 connectors;

- 80 hooks;

- the number of three-meter drainpipes - 14 pieces;

- to them 8 connectors and 24 brackets for pipes;

- screws 160 mm long will need 24 pieces;

- number of bends (67 degrees): two-sleeve - 8 pieces, single-sleeve - 4 pieces.

Single sleeve outlet, mounting scheme

Elbow single sleeve 67 degrees

Important! Do not transport three-meter gutter elements on the roof of a private car, do not store plastic parts under the scorching sun, do not place heavy objects on the lying gutters and pipes.

Prices for different types of pipe bends

pipe outlet

Video - How to choose hooks

The procedure for installing a plastic gutter system

Tools:

- hacksaw for metal with small teeth;

- device for bending metal hooks;

- building level and tape measure;

- screwdriver, dowels and self-tapping wood screws;

- file;

- construction cord (rope);

- adjustable pliers;

- marker or pencil.

Basic principles installation

- The slope of the water intake trays is 3.5 mm per linear meter of length.

- Water flowing from the drip should fall into the central part of the trays.

- The edge of the bracket and gutter must not cross the line of the roof slope.

- If we conditionally continue the roof slope with a straight line, then the bracket should be 1 cm below this line.

Subject to the indicated rules, moisture flowing from the roof will not overflow over the edges of the trays, and in the spring there will be no risk of deformation and breakage of the gutters during an avalanche of snow.

Mounting order

Stage 1. Determine the location of the water intake funnel. It can be located at the edge of the eaves or closer to its middle. But always, regardless of the installation location, the funnel is located at the lowest point of the gutters throughout the entire eaves, that is, the trays should always be tilted towards the storm water inlet.

With a marker or pencil, mark the line where the funnel will be fixed.

Stage 2. Plastic brackets are used to fasten the gutters to the frontal board.

We mark the place of attachment of the bracket. The end hook is always attached fifteen centimeters from the corner or edge of the roof.

We fix the first bracket, not forgetting the main principle of installation: the hook should be located 1 cm below the continuation of the roof slope.

Important to start installation from the extreme hooks in order to set the correct slope of the entire drain.

Stage 3. Using a tape measure, we measure the distance between the installed hook and the place where the storm water inlet will be installed.

Given the slope of 3.5 mm per 1 linear meter, we calculate where the attachment point will be located. For example, if there are 2 meters from the hook to the funnel, then it will be 7 mm lower.

Stage 4. We fix the storm water inlet with self-tapping screws to the frontal board. There are factory holes in the funnel for screwing in hardware.

Important! If there is no front plate, the funnel must be fixed using bracket extensions.

Stage 5. We pull the cord between the storm water inlet and the outer bracket.

Along the line of the stretched laces, we install the brackets on both sides of the storm water inlet. The recommended distance from the edge of the funnel to the bracket is 15 cm.

We fasten the intermediate hooks in increments of 50-60 cm. If the distance between the brackets is made larger, then the gutters are most likely deformed.

How to fix the brackets if there is no frontal board?

Option 1. If the roof is not yet covered, and the design does not provide for a frontal board, either metal hooks or straight bracket extensions that are mounted over the rafters are used to mount the gutters.

on a note! Most often, the pitch of the rafters does not match the pitch of the hooks. In this case, it is permissible to fix the brackets on top of the OSB-3 plates, having previously cut out the notches.

Option 2. If the roof is already covered, then curved side extensions are used to fix the hooks.

The main advantage of extensions is the presence of holes and marks, thanks to which it is easy to set the position of the brackets and adjust the angle of the gutters.

Stage 6. We begin the installation of gutters.

The first step of work is markup. We measure the required length of the gutter with a tape measure, put a mark, then saw off the excess with a hacksaw. We process the edge with a file to remove burrs.

The gutters are laid on top of the brackets.

First, insert the edge of the bracket into the funnel. There are special notches inside the funnel, this is a specially applied marking that takes into account the linear expansion of the material of the gutters when heated.

We insert the gutter from the inside out so that it snaps into place inside the funnel. Press a little on the chute when installing.

Similarly, we snap the gutter into the brackets.

Stage 7. Installing gutter connectors.

The location of the elements is strictly between two brackets, which are fixed at a distance of 10-15 cm from the connectors.

Marking for fixing brackets

We fix the connector to the frontal board in the same way as funnels, with self-tapping screws through the factory holes.

Inside the connector we lay the edges of the gutters, focusing on the notches applied inside.

On a note! Connectors equipped rubber seals for a better seal.

Stage 8. Installing corner pieces. Both on the outer and inner corners of the bath, the elements are fixed equally simply. They do not even need to be screwed to the front board, just snap the edges of the gutters into them.

Stage 9. We install plugs on the gutters.

Note! Depending on the configuration of the gutter, the plugs can be right, left or universal.

If necessary, we also install the plug on the funnel (in the case when it is located close to the corner of the roof), using a small section of the gutter to connect the elements.

Stage 10. At the final stage, we proceed to the installation of downpipes. Installation is carried out from the funnel from top to bottom.

The order of connection of the elements depends on the configuration of the roof, the size of the cornice overhang.

Stage 11. We fix the drainpipes with universal clamps.

Important! Between adjacent clamps should be no more than one and a half meters.

Stage 12. We connect the pipes with couplings, and then we fix the structure with a clamp. Each coupling has a special seat for the clamp.

Stage 13. It remains only to install a knee to drain the water. It is necessary to fix this knee, like other elements, with a separate clamp.

Check the operation of the entire drain by pouring a bucket of water onto the roof (but not directly into the gutter!) Make sure that the water from the roof drains into the center of the gutters, enters the funnel and rushes down the pipes to the ground or storm drains.

This completes the installation. In order for the drainage system to last as long as possible, do not forget to take care of it: inspect the condition of the elements twice a year, clean the trays from large and small debris.

Video - How to install a PVC drain

To prevent water from the roof from washing away the foundation, a drainage system is made. There are they from different materials, more or less expensive, but in general, the costs are solid. You can save a little if you collect the drain with your own hands. About the features and order of installation and will be discussed further.

Types of drainage systems

The most famous and common weirs for the roof are made of galvanized metal. May they not be as attractive as more modern options but reliable and inexpensive. And this is important. What else is good - if you have the skill of a tinsmith, or just having “straight” hands, you can make a drain from galvanization with your own hands.

Speaking of others metal systems, then two of them belong to the elite category - copper and from an alloy of zinc and titanium. They are certainly durable, but the price is very high. There is a more democratic option - metal gutter systems with polymer coating. At a price they are quite affordable, in appearance - you can’t find fault, in terms of durability - it depends on the manufacturer. If technology is followed, they will happen for many years.

There is another type of drainage from the roof - from polymers. They normally tolerate ultraviolet, frost and heat, are highly durable, and look good. The disadvantage can be considered a rather high price, especially of European manufacturers. However, there are good options in the category of inexpensive systems.

Composition of drainage systems

Gutters are located under the roof overhang. They are mounted on special brackets that hold the system. Since the storm drain is located around the entire perimeter of the roof, there are corners - internal and external. All these elements must be connected tightly, for this there are gutter connectors with rubber seals. These elements are often considered redundant. Then the gutters are overlapped with an overlap of at least 30 cm, connected with self-tapping screws.

To drain water, holes are made in the gutter into which funnels are inserted. Downspouts are attached to the funnels. If the roof overhang is large, the pipe is required to be curved. To do this, there are maple or universal rings (some manufacturers have). The downpipe is attached to the wall of the house using special clamps that have the same color as the entire system.

From all these elements, a system of the required configuration is assembled. If you decide to buy ready-made elements, and then assemble the gutter with your own hands, the best solution is to have a house plan with dimensions on hand. According to it, you will quickly determine the composition of the system and calculate the required number of elements.

Mounting Features

Most questions arise regarding the fastening of brackets for the drain. It must be said right away that they are installed taking into account the fact that the gutters should have a slight slope towards the funnels. The minimum recommended slope is 3 mm. If you want the water to drain faster, you can make it larger - up to 10 mm.

If the length of the roof gable is less than 10 meters, the slope is made to one side. If more, either they put an additional funnel (and drainpipe) in the middle and form a drain to it, or the gutter in the middle of the gable has the highest point and the slope goes from the middle to both sides.

When mounting a drain with your own hands, they usually do this: they nail the bracket at the highest point. Then the lowest one is nailed - taking into account the planned slope. A twine is stretched between them, along which all the rest are attached. One recommendation - before forming the slope, check the horizontalness of the line you are targeting. Usually this is either a frontal (wind) board. Unfortunately, it is not always perfectly level. So check the verticality, and preferably with a hydraulic level or, in extreme cases, a bubble one is also suitable, but of great length - at least a meter. For shorter ones at longer lengths, you will not be able to navigate.

Number of brackets and methods of their fastening

The number of brackets for installing a drain is considered simple: the distance between two adjacent ones should be 50-60 cm. Divide the total length of the wall by this distance. We add one to the resulting figure (the end bracket) and get the required amount for one wall. All others are calculated in the same way. If the building has a non-linear shape, you will have to count by the piece - the corner elements must be supported on both sides.

Now directly about the methods of fastening the brackets. There are three possibilities:

Once again, we draw attention to the fact that the brackets are nailed, taking into account the slope created. If they are made of metal, they are bent using improvised means or a special tool - a hook bender (sold in the same place as drains). In this case, the gutter must be positioned so that roofing material ended before reaching half of the gutter, but it is better that it is in the interval 1/2 - 1/3. So most of the gutter "catches" water, which is important during heavy rains.

At what level to mount

Now about how high to raise the gutter to the roofing material. If there is little snow in your region, or the roof has a large angle of inclination, so that snow does not accumulate on it, you don’t have to worry too much and mount it where you like. Otherwise, it is necessary to lower the gutter, so that when the snow melts, the drain does not “come down”.

In the figure, the approximate trajectory of the melting snow is indicated by a dotted line. The far edge of the gutter should not intersect with it. By the way, it should be a couple of centimeters lower than the one located closer to the house.

If it is not possible to lower the gutter below, it will be necessary to install snow retainers on the roof. They prevent massive snowfall. The snow melts little by little, and comes off in small fragments without harming the storm drain.

This is what a massive snowfall looks like. As you can see, the storm drain bracket does not interfere (this is a fitting)

Gutter installation

Gutters are laid in fixed brackets. There are two systems with different sequence of actions. The first has a specially molded groove on the edge of the gutter. The ends of the brackets are threaded into this groove, then the gutter is turned into place, securing it with special tongues on the brackets. If you look at the photo, it will become clearer.

In the second system, installation begins from the side of the gable board. The far edge of the gutter is inserted into the locks located there, then alternately pressed into the locks on the front of the brackets.

Two fragments of the gutter must be connected with a special connecting element with rubber seals. But their cost is quite high, so two gutters are simply overlapped with a 30 cm approach (make sure that the joint is located along the water flow). For greater tightness between the two gutters, you can lay a strip of rubber, and connect them with ordinary self-tapping screws (or with washers and rubber gaskets). After installing the gutter, its edges are closed with plugs.

Funnel attachment

Having assembled and installed the gutter on the brackets, the installation of the drain continues with the installation of funnels. They are placed in the lowest areas. If the funnels are located close to the corners, stepping back from the edge of the gutter about 20 cm, a hole is cut with a hand saw. It is better not to use a jigsaw or grinder - it is likely that your cutout will be too large.

A funnel is attached to this cutout, clinging to the outer edge of the gutter. Then it starts up to the second edge and is fixed there with special clamps.

Installation of downpipes

Downspouts are attached to the funnels. If the roof overhang is large, a rotary element is attached directly to the funnel, which allows you to bring the pipes closer to the wall and fix them there. For fastening there are special clamps, painted in the same color as the entire system. They are of different designs, but mostly they have a latch so that they can be dismantled without removing the screws that fasten the pipe to the wall.

Clamps are installed at a distance of at least 1.8-2 m from each other. At the bottom, the drain can be led directly into drainage system(if it is located nearby). If it is made simply around the foundation, the drain pipe ends with a rotary element that diverts water from the foundation to a distance of at least 20 cm.

In principle, a do-it-yourself drain is installed, but there is one more detail that will make operation much easier. A metal (preferably stainless) mesh is laid on the gutter. It prevents leaves and other large debris from entering the system.

Installing a grid will allow less frequent maintenance of the system. This is especially true in tall buildings.

Homemade drain

Ready-made drainage systems are good, but not cheap. What to do if drainage needs to be done in the country and spend a minimum for this? There are several very affordable options. The first is to make a drain out of plastic sewer pipes. Take pipes of large diameter (110 mm and more), good quality with a thick wall, cut them in half and use them as gutters. As downpipes, you can use the same diameter or a little less. Brackets are more convenient to buy ready-made, but in principle, you can do it yourself. For more information on how to make a drain with your own hands from sewer pipes, see the video.

An even more budgetary option is drainpipes made of plastic bottles. The gutter of them cannot be made normal, but the funnels of the pipe work normally.

Rains, especially slanting showers, can ruin the walls and foundation of almost any structure. Quality and reliable system drainage is the key to the longevity of a building. The process of installing a drainage system does not have to be left to professionals. Having studied the intricacies of the work, you can install the drain on your own.

Peculiarities

Systems designed to collect rainfall are a desirable element in the arrangement of any home. Modern projects housing often already implies its existence. The option of creating gutters at the stage of installing the lathing under the future roof is most often used. However, no one cancels the possibility of installing gutters and pipes on an existing roof.

Gutter systems are distinguished by a variety of designs and available materials. For example, not so long ago, systems were made only from galvanized steel. This material was the only available option. Modern products are also metal, but they are covered with polymer compounds. Gutters are also made of plastic.

Each material has its own qualitative characteristics, which are worth considering in more detail. So, Today on sale you can find drains:

- galvanized;

- metal;

- with a polymer coating;

- plastic.

Gutter systems made of plastic have recently become increasingly popular. This is the best option, since the plastic that is used for gutters is not afraid of temperature changes, it is resistant to frost and heat. plastic pipes not afraid of corrosion processes. The negative impact of ultraviolet radiation on plastic pipes also does not threaten.

Plastic brackets are usually wide, so they provide a snug and secure fit. The disadvantage of plastic gutters is the inability to bend the structure, as is the case with metal parts. Structures are usually tailored to specific design dimensions. Another significant disadvantage of plastic systems is their high cost.

Metal gutters, equipped with a polymer coating, have a lower price. The operating life of such systems is quite long. External natural influences are also not terrible for such drains. They look quite presentable. However, if the polymer coating is damaged, corrosion often occurs on such structures. It is not difficult to damage the coating, sometimes it happens even when installation work due to conventional fasteners.

Most inexpensive look systems - galvanized steel options. Despite the cheapness, such gutters are not very popular, because usually they are not aesthetically pleasing. Systems have a long service life, corrosion can only appear with deep scratches. Main positive quality metal systems - the easiest fitting of parts to the desired configuration.

As for supporting fasteners, they can be sold both as a set with the main system, and separately. The holders must match the shape of the gutter. This question can also be based on technical requirements SNiPs and GOSTs.

Technical requirements

The number of brackets according to SNiP is calculated according to the standard distance between the fasteners, which should be 50-60 cm. To calculate the required number of fasteners, the total length of the system must be divided by this distance. If the building has a non-linear shape, then you can calculate the total in relation to each wall. Corner elements must be counted in pieces, since the drains located at the corners must be adhered to on both sides.

Brackets can be attached in several ways.

- To rafter system roofs. This option is suitable for roofing material that has not yet been laid.

- To the wind board. This option is the only one in case the ebbs are made of plastic. With other materials, this is one of the possible options.

- To the last board of the sheathing under the roofing material, if it is solid.

This method is also suitable if the roofing material has not yet been laid. GOST suggests that the brackets should be mounted taking into account the slope of the system created. The easiest way is with metal options, since they can be bent with improvised means.

According to all the same regulatory parameters, the gutter must be placed so that the roof covering ends before reaching half of the gutter. The correct location of the gutter is 1/2-1/3, this will allow the system to capture water even during heavy rain showers.

Normative rules also imply the optimal choice of the placement of the structure. For example, it is not recommended to install the gutter high in snowy regions, as well as on roofs with a small angle of inclination.

If the region of your residence is not snowy, and the roof has a sufficient slope, you don’t have to worry too much about the location of the structure. If a low gutter does not work, then additional snow retainers can be installed. The snow will come off the roof little by little and will not harm the storm system.

In addition to fasteners, it is important to correctly calculate the number of pipes and gutters. It is also worth considering that if the diameter of the system is displayed incorrectly, then it will not be able to divert the required amount of water from the roof, or it will cope, but it will turn out to be unreasonably expensive.

There are certain principles for calculation.

- For surfaces with total area slopes up to 50 sq. m. use pipes 75 mm and gutters 100 mm.

- For surfaces ranging from 50 to 10 square meters, pipes with a diameter of 87 mm and gutters of 125 mm are used.

- For roofs with a quadrature of more than 100 square meters, pipes with a diameter of 100 mm and gutters of 150 mm are relevant.

The project of the drainage system on paper will simplify the task of choosing all the constituent elements. All data on your intended design must be reflected schematically. For this work, knowledge of the types of systems is useful.

Kinds

When arranging a residential building, various drainage systems can be used. The most popular option is attached outside the structure and is a combination of various elements in which water can accumulate. For further removal of moisture, a storm sewer or a well is sometimes equipped. Summer residents install ordinary barrels to collect water, which can later be watered in the garden.

This version of the drain system is called organized, external. However, it is not suitable for flat roofs. Here the best choice there will be a storm funnel, which is usually round in shape. Water enters the drains into the funnel, then goes into the pipes and goes to the sewer. The required number of such funnels in the roof is determined by regional natural factors, as well as the roof area.

The internal drain can work on a gravity system. Also, sometimes they equip a version of the system with a siphon. Such systems require a small amount funnel. In drains, where water must flow by gravity, the flow rate is determined by the angle of the gutters.

Experts identify another type of drainage system, which is classified as an unorganized type. Such a drain is a roof with a properly equipped slope. Moisture freely flows down along it, while the facade of the building does not “suffer” at all. However, due to the fact that water falls close to the foundation, the risk of its destruction increases. This option is suitable for one pitched roofs. In this case, it is desirable to make a slope towards the courtyard.

Such roofs are rarely used for residential buildings. According to SNiP, unorganized drains are allowed only on high-rise buildings. In addition, for the possibility of arranging an unorganized drain, experts calculate the annual amount of precipitation in the region. It should not exceed 300 mm/year.

Balconies should not be placed on the part of the building where the ramp faces. Also, there should be no roadways, pedestrian zones.

Roofing equipped with a visor with a length of at least 60 cm. good protection unorganized drainage will not provide residential buildings.

There is another option for a drain, called a drip. It looks like a plank fixed on the pediment or cornice of the structure. The drip is a good protection of the facade of the house from moisture. It works like this:

- water gets on the plate;

- then it overflows into the gutter;

- The sludge then enters the drainage system.

Device different types drainage is different. Let us consider in more detail the traditional systems of the external and internal type.

Device

The device of an internal drain involves the placement of pipes inside buildings. Such a system does not allow pipes to freeze and is well suited for regions with very changeable weather. The advantage of the system is that the pipes are not visible from the facade, which improves the exterior. A feature of the device is the mandatory presence of drainage or a special place where rainwater enters.

The device of the system requires the mandatory presence of:

- pipeline;

- receiving funnels with a collector;

- special cleaning systems.

Unlike the first option, the external drain is placed on the facade of the building. Most suburban private buildings are equipped with just such a system. Its main convenience is that the drainage device is allowed after construction. With an internal drain, this option will not work.

The advantages of an external device are as follows:

- simple installation;

- simple care;

- there is no need for professional knowledge and skills.

In addition, a variety of materials can be used for outdoor systems.

Material calculation

To calculate materials according to SNiP, the following data is required:

- roof area;

- the amount of average annual precipitation;

- temperature minimum in winter in the region;

- availability of rainwater.

This calculation helps to determine the number of gutters, or rather the total length of the overhangs, which is divided by the length of one gutter. For example, the total length of the overhang is 40 meters. Subtract the length of the corner elements (15 cm per side) It turns out: 12 * 15 \u003d 1.80. Then: 40 - 1.8 = 38.2 m.

The standard length of one galvanized gutter is 3 meters. This means that 13 gutters will be required (38.2 / 3 \u003d 12.7). The number of connecting elements is selected according to the number of joints in the structure. A drawing will help you with this, on which you need to depict a rectangle with schematically located drainage elements. For our example, 18 couplers are required.

The number of brackets for fastenings is calculated based on the total length divided by the standard pitch. For example, for plastic it is 60 cm, and for metal it is 70 cm.

If the system is not closed, and the gutters will be mounted with open ends, then you need to determine the number of plugs. For example, for a gable gable roof, on which the system is mounted in two threads, you need to install four plugs. If the roof is hipped, tent type, plugs are not required at all.

The number of corner elements will be equal to the number of external and internal corners of the house. The number of pipes is chosen in such a way that it coincides with the number of drains, and their length must correspond to the height of the structure. In some cases, curved knees are needed. Their need is determined by the width of the overhang.

A clamp must be put on each section connection. If the pipe is three meters, then there should be two clamps: one on top, the other on the bottom.

The outlet must be located 30 centimeters from the ground (it can be lowered up to 15 cm, but only if there is a collector).

The calculation of the internal drainage is carried out according to the rule - one funnel per 0.75 square meters. The pitch between the funnels is determined by dividing the length of the roof, measured along the longitudinal axis, by the number of funnels. In addition to water inlets, the system will require:

- risers;

- outlet pipes

- release.

For internal drainage, you can choose pipes with a diameter of 100, 140, 180 mm. The length can be 70 or 150 m. The incoming moisture is transferred to the storm sewer. If the drainage system is supposed to be used year-round, then the system is best placed in a heated area.

The internal system often suffers from debris that can enter it from the roof. The protection design is extremely simple - a cap and a glass. This is an auxiliary element, but it copes well with the retention of various debris.

Such an auxiliary device is not required if the internal drain is installed with a siphon. This is a special valve for storm sewers connected to a drain. It keeps the pressure of the water in the pipes. When filling the drainage system, the valve opens, a very rapid release of precipitation occurs. The formation of blockages in the siphon system is rare, it is practically not necessary to clean it.

Mounting

Do-it-yourself installation of gutters will be correct if you strictly follow the instructions. It will be more convenient to mount by considering a specific example in detail. According to the example, it is possible to make a drain after laying the roof covering.

To collect outdoor system according to this scheme, long brackets for the gutters will be required. The brackets will need to be attached to the bottom board. In our example, the roof covering material is tiles. Therefore, here it is enough to raise the elements of the roof covering laid in this row.

For the effectiveness of the gutter system, it is important to properly prepare the brackets. Fasteners must first be tried on. Please note that the edge of the gutter should not protrude beyond the line of the roof slope. Ideally, about 2 cm should remain between the edge of the hook and the slope line. After trying on, markup should be applied. The first hook in any case should be located above the last.

For fitting, the first hook must be laid to the place of the upcoming installation. A rule or a regular rail is installed directly on the slope. Measure from the bent part of the hook to the rule about two centimeters. Mark the fold point. SNiP condition - the gutter should overlap the edge by a third. Find a point that meets this condition. Place a mark on the bracket leg.

Find the slope to the water intake. A running meter of a cornice is about 3 mm slope. In the example, there is 12 meters of drainage, which means 3 * 12 = 36. This should be the difference between the first and last hooks. Draw a fold line. To do this, lay out the brackets in the required quantity in a row and draw an inclined line on their legs. Number the marked hooks.

Bend the holders with a special device that optimizes accuracy. A vice can be used for work, but only if the hooks are not coated.

To ensure that the slope is observed, first attach the two extreme brackets. Stretch a control line between them. Fastening of ordinary hooks is carried out according to the marked distance. The main work has been done. It remains to install the gutters and funnel. Carry out another stage of fitting, but already to the gutter, or rather to that part of it, to which the gutter riser will be attached.

To find the exact place to drill, it is better to put a plastic funnel on the gutter.

Mark the hole with a marker and then punch it into the gutter. A hacksaw is suitable for forming a hole. The tool makes two counter washed down. The edges of the cuts and the drilled hole are cleaned with sandpaper. Next, you need to mount the funnel on the gutter and secure it with special latches. Mounting the system to a flat wall is simple, just fix it on hooks and fix the funnel nozzles with glue.

On the roof, the installation of the system begins with gutters with a funnel. Reinforce gutter parts with connectors. It is desirable that the inside of the connectors is also covered with glue. If needed, then last step plugs will be attached. They are needed to collect water from pitched roofs with two drains.

The assembly of vertical risers begins with the assembly of the knees. If the construction of the structure has a wide cornice, then there will be more stages. Here again you will need to try on. It is carried out after joining the funnel of the first knee to the nozzle. Attach the lower knee to the installation site on the wall. Use a ruler to measure the distance between the pieces.

Then proceed to cutting the connecting segment. The transition from the drainage system to the drainage system can be located at an angle. Connect the parts with couplings with installed clamps. Do not overtighten the clamps. The drain to the downpipe must be fixed with glue.

Drain is not required if rain water will be collected in the storm system. The end of the pipe may be located above the gutter, at a distance of several centimeters from the surface. To prevent the gutters from becoming clogged with debris, it is recommended to cover them with gratings.

- The heavier the material of the pipes, the smaller the distance between the hooks should be. All auxiliary parts (hooks, funnels and plugs) must be installed before the installation of the main gutter line.

- Copper is considered the most durable material for drainage systems. Copper pipes do not react in any way to atmospheric phenomena. The service life of copper parts can be more than one century. However, such a system is expensive. It will not pay for itself if it is installed on a modest house or a simple industrial building.

- Methods for connecting elements are selected depending on the material used in the construction. For example, for plastic, the cold welding method, using clamps, using rubber seals, will be relevant.

- In areas with cold weather conditions, heating of the gutter system can be installed. This pleasure is not cheap, but it effectively prevents icing, and hence the collapse of the entire system.

- It is not necessary to cut metal gutters with an angle grinder, especially if these are elements with a polymer coating. The best tool for cutting gutters is a hacksaw.

- Do not forget about the need for periodic cleaning of the system. Open gutters are easily clogged with fallen leaves, and small debris and dirt get into the pipes. The debris that has fallen into the drain will have to be removed manually. A good pressure of water, for example from a hose, will help in cleaning. There are specialists who will perform this work for a monetary reward.

- It is better to mount the gutter with all connections and plugs on the ground. To lift the system under the roof, you will need an assistant. If a person works alone, then it is better to assemble the system upstairs, under the roof, but this is not very convenient.

- Optimum bonding adhesive PVC pipes- two-component, based on a polymer compound (the second component is tetrahydrofuran). It is a heat-resistant composition that is resistant to chemical aggressive substances. Hardening of substances is observed for 4 minutes. Glue is sold in containers weighing from 0.125 to 1 kg. The mechanical strength and safety margin of such an adhesive composition are very high.

- For metal, clamps and seals can be used. If you are unable to install the system, then it is better to call professional installers for installation. The work will be done efficiently and quickly.