Do-it-yourself concrete porch: the beginning of construction work. Making a concrete porch How to build a concrete porch with your hands

The porch is the most important part of the exterior. country house. A beautifully executed entrance is a real decoration of the entire building, a detail that attracts attention and creates a sense of solidity. In this article, we will consider the most simple and accessible method for everyone, with which you can build concrete steps for the porch with your own hands.

lined porch

Advantages of concrete steps for a porch

Steps ready

Concrete mortar is just a great material for building steps. Stair construction from such material, reinforced with reinforcement, is able to serve the owners for decades without repair (see also the article " Cesspool from concrete rings suburban area: practical recommendations for self-construction).

A porch of this kind, regardless of whether ready-made concrete steps were used for the porch during its creation or not, has the following important characteristics:

- No noise. Such steps do not creak like wood and do not create a hum effect. The monolith absorbs all possible sounds;

- Not afraid of rust, rotting processes and insects;

- Not afraid of fires and high temperatures;

- Can be veneered with any finishing material. Thus, it is possible to hide the concrete accessory and design the structure as a wooden one, for example;

- Repair in the presence of any damage on such a product will be inexpensive;

- A porch made of concrete can be endowed with the most unimaginable shape and have any required size.

Technology for the construction of steps for arranging the porch of a building

Ready-made monolithic structure

The external attractiveness of the porch directly depends on the quality of all construction work and compliance with existing building codes and regulations (see also the article “Mosaic concrete for the manufacture of a beautiful floor with marble chips”).

Violation of technology during the construction of even such a seemingly insignificant structural element can result in the following defects:

- The formation of cracks on the walls associated with the porch;

- Peeling of the finishing decorative layer from the surface of the porch;

- Subsidence of the porch relative to the building itself.

Correcting such defects is difficult, and in some cases even impossible.

Advice. Following all the norms during the construction process will allow you to avoid the time and effort associated with the dismantling of a reinforced monolithic product and the construction of a new one, which can double such a parameter as the price of erecting a concrete porch.

In order to save own forces and means it is important to follow three basic rules:

Advice. The connection of the foundations of the house and the porch is made by means of mutual reinforcement.

Advice. When erecting this element of the structure, one should not be too presumptuous and, subject to the lack of experience in the production of such work, one should still use the finished project.

Materials and tools required for work

For the construction of the porch, you will certainly need the following tools and materials:

- Portland cement;

- gravel-sand mixture;

- Reinforcing bar with a diameter of 6.5 mm;

- Wire for knitting fittings;

- Perforator with a set of drills for concrete;

- Special equipment with the help of which diamond drilling of holes in concrete can be carried out;

- Vibrator for compaction of the solution;

concrete vibrator

- Boards for the construction of formwork;

- Bars as formwork racks;

- Bulgarian - a tool with which reinforced concrete will be cut with diamond wheels;

- Concrete mixer;

- Electric saw for cutting boards and formwork bars;

- Shovels of two types: shovel and bayonet;

- Hammer with nails for the construction of formwork;

- Wheelbarrow for moving the solution;

- waterproofing material;

- Tool for knitting reinforcing wire.

Tool for knitting reinforcing corset

Preparatory activities

Territory preparation

Before starting work, the area for arranging the porch must be prepared:

- The construction site must be cleared;

- You should make markings under the foundation of the porch;

- Digging a foundation pit;

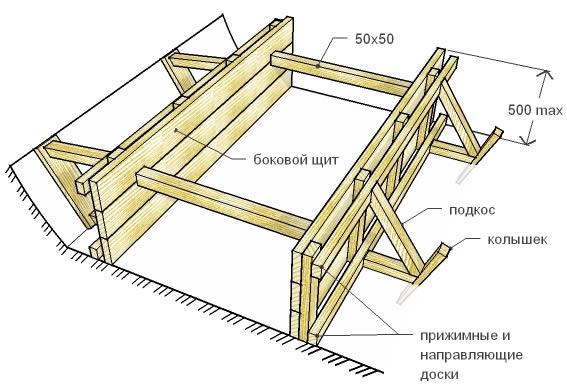

- Installation of wooden formwork for pouring the foundation;

- Installation of fittings under the porch;

Advice. To implement the method of mutual reinforcement, holes for reinforcement should be drilled in the foundation of the house.

- The prepared trench is covered with concrete mortar;

Advice. The solution is prepared from Portland cement and sand-gravel mixture in a ratio of 1/4. Water is added to the solution until a mass of the consistency of liquid porridge is obtained.

- Using a vibrator for concrete, we compact the structure;

Pouring the foundation under the porch

- We cover the poured foundation with burlap and let it harden for 3 days;

- We remove the formwork and cover the concrete with roofing material or cover it with molten tar.

Construction of formwork for steps

After the foundation is ready, it's time to think about the construction of the most concrete porch steps.

Instructions for arranging the porch consists in the implementation of the following actions:

Advice. The height of each step should not be more than 20 cm, and the width should not exceed 30 cm. The width of the porch should be 20-30 cm protruding from each side of the front door.

In the photo - formwork covered with roofing material

Advice. If it is planned to build a railing, then at this stage reinforcement should be made in such a way that the branches of the rods rise 4-5 cm above the level of the steps.

Formwork filled with mortar

Decorative porch steps

Decorating the porch with cladding

For decoration, concrete tiles for the steps of the porch, decorative or natural stone, or ceramic tiles. The side walls can be decorated with bricks, foundation siding and other facade finishing materials suitable for the design of the building.

Finally

One of the design options

Concrete steps for a porch are an excellent, durable product that, if properly finished, can please the owners of the building with its convenience and visual appeal for more than one year (read also the article “Slag concrete - everything you need to know about this type of material”).

It is absolutely easy to build such a structure with your own hands, but in order for the final structure to be durable, you should take care in advance not only of using high-quality materials, but of observing building codes.

You can learn more about what concrete steps are like by watching the video in this article.

Or concrete. The latter does not rust or rot, and therefore the structures made from it are the most durable. In addition, the construction of a concrete porch is not a very complicated operation.

In order to build it, no special skills are needed and no expensive equipment is required. All that needs to be done is to knock down the formwork and knead the cement mixture of a suitable composition. But let's talk about everything in order.

Preparatory work

Cement porches are usually made rectangular. Sometimes their shape is also semicircular. Both options are filled in exactly the same way. Only the methods of making formwork differ. The cladding of the structure can also be different - from stone, tile, wood, etc. In any case, the procedure for erecting and finishing a concrete march should be carried out carefully and slowly. And then you will get a very beautiful concrete porch with your own hands. For example, such as in these photos:

Design

How to finish a concrete porch with your own hands. Photo of a tiled structure

How to choose the right tile

For facing the porch of a private house, you should choose non-slip tiles with a rough surface. Finishing is carried out using only a frost-resistant option. It is not necessary to make the march monophonic. You can buy tiles of different colors and lay out a real mosaic on the steps. Note: Concrete porches look very nice, the steps of which are finished with plain tiles, and the risers are ornamented to match.

It is not necessary to finish the porch with plain tiles

Cladding technology

You need to glue a concrete porch with tiles using the following technology:

- All dirt and dust is removed from the surface of the porch;

- The adhesive is applied to both tiles and concrete. Don't just make the layer too thick;

- The tile is pressed tightly against the surface of the porch;

- Spacer plastic crosses are installed between the individual elements;

- The next day, the joints are grouted with a special grout matched to the color of the tile.

The procedure for laying tiles on the steps

Finally, we suggest you watch a video on how to make a porch and save on cement:

We hope we have given a more or less detailed answer to the question of how to fill the porch with a semicircle or rectangle. As you can see, the main difficulty in the manufacture of such structures is the assembly of reliable formwork of the required shape and the knitting of reinforcement.

In order to comfortably climb into the house, you need to make a porch. It can consist of one or two steps, or it can be at a decent height - it all depends on the basement of the house. In any case, the structure must be durable, therefore, before pouring the porch, the site should be freed from everything superfluous - the old porch (if any), debris, grass, young growth of nearby trees. The construction technology begins with this.

Preparatory process

To build a comfortable porch in a private house, you should calculate the dimensions of the entire structure, prepare the site, and you can begin to build the foundation. The latter must be present, albeit small. And if the soil on which the house stands is clayey, the foundation pit breaks out deep enough (up to 70 cm) and is reinforced with a mixture of sand and gravel. They are laid on the bottom, forming a kind of pillow, and only then they form the main foundation for the porch of a private house.

With dense soil, a pit with a depth of 30-35 cm is sufficient. A concrete porch should be comfortable and safe - the site should be leveled, and only high-quality materials should be used. Since this design will be constantly exposed to temperature changes and the influence of precipitation, it must also be especially durable, so the process of creating a porch is an exact observance of technology and calculation.

Types of concrete porch

In addition to size, you should also decide on the shape. It is rectangular, square, round, oval. You can also attach a trapezoidal concrete porch to the house. It all depends on the taste of the owners and their imagination. But you need to make sure that the shape is in harmony with the overall appearance of the facade, otherwise it will look alien. A porch with a staircase can be located either on the side or on the front facade of the house (by the way, you can make several entrances, but then the process of building the porch will be somewhat delayed).

Concrete - great choice material to create a porch. It can be faced with stone, tile, even wood and is stronger than other materials. Create monolithic porch from concrete with your own hands is not so difficult if you follow the technology, but some nuances should be taken into account.

If the staircase is designed higher than 5 steps, holes for future railings should be left at the stage of concrete curing. The same applies to the canopy - supports for it are installed during the manufacture of the porch.

Design

- make the porch wider than the door by 3-5 cm in each direction;

- and the height of the porch should not reach about 5 cm to the door frame;

- the foundation pit will be even slightly wider than the site - by 4-5 cm (this is an allowance for the thickness of the formwork boards);

- also need to be calculated very carefully. It should be at least 30 cm - designed for an average foot size. And the height of the steps is about 20 cm. With a larger one, it will be difficult for children and elderly people to climb into the house;

- the upper platform is convenient with a width of 80-100 cm;

- the stairs should be made inclined - 30-45 degrees is enough. So the rise will be comfortable, and the water will not linger after precipitation;

- the width of the staircase itself can be equal to the size top platform- 80-100 cm.

Calculation of materials for the porch

At this stage of construction, it is necessary to find quality materials for assembly, pouring, reinforcement and so on.

You will need:

- Formwork boards.

- Mesh for reinforcement.

- Crushed stone and sand.

- Cement brand M400, and better M500.

- Materials for waterproofing.

- Water.

- Accessories (self-tapping screws and corners).

You can also use ready-mixed concrete. But by mixing it with your own hands (more precisely, with a concrete mixer) and controlling the number of components, you can achieve better quality. To obtain a good solution, you should mix 1 part of cement with 2 parts of sand, but crushed stone needs 3.5 parts of the norm of cement. For 1 cubic meter of concrete, about 190 kg of M400 cement will be needed. Therefore, in order to calculate the amount of material, you should understand how many cubes of finished concrete will be needed for pouring. And do not forget about the layer of rubble and sand at the depth of the foundation.

As for the reinforcement, it is believed that at least 2 rods should be spent on each step. Most often, they take material with a cell size of 10x10 cm. It fits best into the formwork. For reinforcement calculations, it is worth measuring the quadrature of the lowest step and multiplying this figure by the number of steps.

The boards will be used to create the formwork. For each tier, that is, steps, you should take 3 boards about 2 cm thick. Do not take too dry material - it will crack under the pressure of concrete. Frame blocks for the porch should be fastened together with self-tapping screws, and the corners will help to install them evenly. The latter are needed only for a square or rectangular porch.

Design features

If the foundation is deep, you can scatter any non-combustible garbage along the bottom - foam blocks, broken bricks, even glass. But from above, all this is covered with an even layer of a mixture of sand and gravel.

The reinforcement should be cut in advance into pieces of the desired size, it is not laid on the bottom, but on single-standing gas blocks or bricks - this way it is all evenly covered with mortar and the concrete porch will be stronger.

Formwork on all sides can be further strengthened with pieces of timber or thick boards. Formwork material should be lubricated from the inside with a special compound - then it will be easier to remove it upon completion of construction work.

Concrete mortar is sometimes supplemented with various additives that give the desired level of plasticity, make it frost and water resistant.

If a porch with steps is attached to an already erected house, it is necessary to leave a gap of about 10 cm between them. This is done so that, in case of possible deformation, the foundation of the house is not damaged and a so-called “temperature seam” is created. In this space, you can lay a wooden shield and hammer it with glass wool.

Design advantages

- The main advantage is that you can make a concrete porch with your own hands. If you correctly calculate the amount of materials, follow the technology and do not save on quality, it will be durable and beautiful.

- Materials for arrangement need the most common, which can be easily bought. They are not in short supply.

- Such a porch is easy to make original, since it can be lined with stone, tile, wood, and other materials. You can also use a mixed version.

- The end result is relatively inexpensive. You can choose the shape and size.

Design cons

Sometimes the porch quickly begins to collapse - crumble, settle, loosen. This means that during the filling process, its technology was violated. It is necessary to properly fill the porch of the house. As an option, poor-quality material was caught, so its quality should be monitored especially.

We make the foundation

To make the foundation of the porch poured easier and faster, in addition to materials, you need a small concrete mixer. The solution must be developed within about an hour and a half after its manufacture, then it will harden and crumble.

The reinforcement bars are cut into pieces of the desired size and fastened together with a wire. So concrete staircase the porch is durable and does not fall apart over time. Ready-made steps of the porch can be additionally fixed with corners.

It is necessary to dig a hole according to the size of the foundation with an allowance of 2 cm from each side. Next, crushed stone is placed on the bottom with a layer thickness of 7-10 cm (you can add any construction waste to save material). The same layer of sand is laid on top, carefully ramming it. Sheets of roofing material are sometimes also placed on the sand. The site must be level. This is followed by gas blocks, reinforcement and finally concrete.

Site preparation

It is thoroughly cleaned of everything superfluous - debris, bushes, grass. If we make a foundation with our own hands, we dig a hole 30 cm deep (if the soil is strong enough). With doubtful soil, the depth of the foundation should be greater. Mandatory waterproofing and leveling the site with sand and gravel. Pegs for the future formwork should be hammered along the perimeter of the site.

How to prepare concrete?

This is a mixture of cement, sand, and crushed stone in certain proportions. All this is poured into a concrete mixer and water is added. The consistency of the concrete should be pasty - not spill, but not too dry. It should be easily spread with a shovel and compacted. Sometimes concrete is supplemented with special additives to improve its technical qualities.

Reinforcement principles

The consumption of fittings for a medium-sized porch is about 160 meters. Its thickness should be at least 10-12 centimeters. Reinforcement is the binding of reinforcement with wire in a certain configuration. On its quality, like other materials, you can not save. At the edges, pieces of reinforcement should be left for future railings.

Installation of a concrete porch

After preparing all the components, as well as the area under the porch, you can begin its installation. To know exactly how to make a concrete porch with your own hands, you can watch a training video or work with experienced craftsmen.

The weather should be clear and moderately warm. You should go through all the stages one by one, without missing anything. 6-7 days after the end of work, you can start producing finishing porch.

We install the formwork

Boards for it are installed along the perimeter of the pit and fixed with spacers. They should be wider than future steps due to the fact that part will go into the depth of the pit. The formwork for the porch is placed straight, fastened with self-tapping screws and, if necessary, with corners. You will also need stiffeners - they strengthen the sidewalls.

If only dry boards are available, they should be moistened with water. The shape of the formwork must exactly repeat the outlines. A do-it-yourself trapezoidal concrete porch is more difficult to create than a rectangular one, but it looks much more spectacular.

On the concrete blocks or another support at least 5 cm high, reinforcement bars cut as necessary are laid. They are tied together with wire, preferably steel. It must be ensured that the reinforcement is not subject to corrosion.

Creating a solution

It requires cement of a grade of at least 400. The solution from it is quite strong. Cement is mixed with sand and gravel in proportions of 1: 2: 3.5, respectively. Then water is added for the required viscosity of the solution. The mixture is thoroughly mixed in a concrete mixer and after that it is considered ready. It should have a uniform, fairly plastic consistency.

Before you make a concrete porch with your own hands, you should think about and check everything. It is necessary to proceed directly to concreting fully armed, because after it there is little that can be corrected. After the foundation pit has been dug, a layer of sand and gravel has been covered, reinforcement and formwork have been installed, the concrete mixture can be poured.

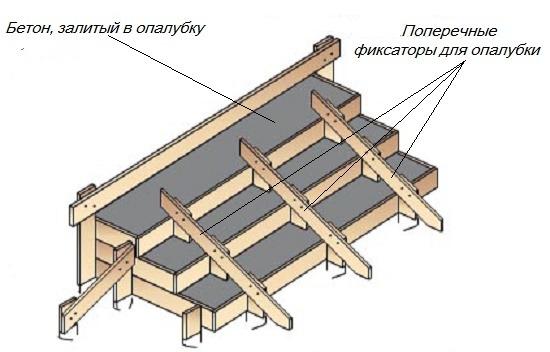

It must be tamped down in the process of pouring the steps, carefully distributing it with a shovel over the pit. Be sure to get rid of the air bubbles that appear in the solution. It is better to place the mixer as close as possible to the place of pouring. We fill the concrete porch in layers: we leave the first layer to harden a little, then the second, third, and so on follow the number of steps. At the end, we cover the finished structure with a tarpaulin or roofing material.

Concrete porch cladding

To finish the concrete porch, you should first clean it to smoothness, you can manually, you can use special tools. After that, it is painted, lined with stone, tile or wood. Color, shape and surface type facing material everyone chooses independently.

Clinker tiles look great, besides, it also does not slip. Many make a choice in favor of porcelain stoneware tiles. The cladding process in both cases is the same. The surface of the tile is smeared with special glue and pressed tightly against the desired area of the porch. When the cladding is finished, cross spacers are inserted into the seams to keep the tiles from moving. Then they are removed, and the seams are overwritten. special mixture. On this, the device of the concrete porch can be considered complete.

Final step by step instructions

So, in order to properly fill the porch of concrete, you must do the following:

- Clear the place.

- Dig a pit.

- Install formwork.

- Make waterproofing, fill the bottom with rubble and sand, you can use construction waste, compact it.

- Make sure that the surface of the concrete floor is even, cover it with pieces of roofing material.

- Install gas blocks, lay prepared reinforcement on them, tie the rods with wire.

- All actions starting from the formwork should be repeated according to the number of steps.

- Pour all the steps with concrete solution in stages.

- Cover the finished structure with roofing felt or tarpaulin.

- After a week, you can remove and clean the surface.

- Make a lining to taste.

The result is one of the most beautiful structures - a do-it-yourself porch that you can be proud of.

It is not difficult to make a porch out of concrete with your own hands. But first you need to think through all the details so that when you enter the house, you do not stumble on uncomfortable steps, and the structure itself will serve you for many years. The concrete porch is very popular among the owners of private houses, as it does not rust or rot. The materials are inexpensive, and you can assemble the formwork and pour concrete into it on your own. In addition, manufacturers offer the most different types finishes, so no one will know what your porch is built from.

It's always hard to start. Questions about the shape, finish, number of steps and other things will immediately arise in your head. A good drawing and miscalculation of all materials will simplify the work itself.

First, walking should be comfortable and safe. Therefore, equip a small area in front of the door, it should be 50 mm lower than the door. Build the stairs at an angle of 25 to 45 degrees. The recommended step height is 200, and the width is at least 300 mm, these are the stairs that are made in multi-storey buildings. If the steps are higher, children and the elderly will not be able to easily enter you. The porch itself should not be narrower than 0.8 m, this place is enough for one person to walk freely on it.

2. Foundation.

The question of whether to build a foundation for a concrete porch or not does not have a definite answer. It all depends on the design itself and the type of soil. If you need an ordinary staircase of 3-5 steps with a small platform in front of the door, and your house is located on good ground, it is not necessary to make a deep foundation. But if you have already drawn a drawing of a huge staircase with a canopy, and the house is on clay soil, you will have to pour a reliable foundation with concrete. Since it would take a whole book to consider all the options, in this instruction we will analyze how to make a concrete porch with a small foundation.

Clear the site of debris and plants. Dig a hole at least 300mm deep. We recommend isolating the future structure with polystyrene foam or other material that does not allow steam and moisture to pass through that forms in the ground. This will not only add strength, but also increase the life of the finish.

If you decide to completely fill the future porch with concrete, fill the hole with a layer of crushed stone 50 and a layer of sand 100 mm soaked in water. To reduce the consumption of materials for a medium-sized structure, you can not do complete concreting of the entire space; for this, add sand to the height of the upper platform and stairs, tamping it well.

To build a solid large porch on unstable soil, it is necessary to build at least a columnar foundation, the Internet has detailed instructions how to make and pour concrete pillars. Otherwise, the system will be unreliable.

Another question that can only be answered by knowing all the characteristics. It is better to tie the porch to a new private house that did not have time to settle, ideally, pour the foundation and the platform with the stairs at the same time. The problem of binding to an already settled house is resolved on an individual basis, since due to the uneven shrinkage rate in conditions of unstable soil, there is a high probability of rapid cracking. The design of the formwork will depend on what decision you have made.

3. Formwork.

For the side and bottom faces of the formwork, plywood reinforced with timber, or durable boards no thicker than 20 mm, are suitable. If the wood is dry, wet it, and plan the areas that will touch the concrete. The formwork should be 200–300 mm higher than the future porch, depending on the strength of the soil. Use self-tapping screws and corners to fasten parts. Make sure there are no gaps. Strengthen the system by making strong props.

First, the side formwork is installed, it should be at a distance of 100 mm from the wall if you decide not to connect the porch and the house. A roofing felt is attached to this space and a layer of sealant is applied. Then boards are mounted to outline the contour of future steps. After that, the formwork is lubricated from the inside with a special mixture to facilitate the disassembly of the structure.

4. Reinforcement.

We recommend using ribbed reinforcement. The elements are interconnected with a soft wire or welded. To make the porch become one with the house, drill small holes in the adjoining wall and insert the ends of the reinforcement there.

The distance between reinforcement layers is 150 mm, and the step in any direction is 150–200. Additionally, it is necessary to outline the contours of each step. The minimum distance to the formwork is 40 – 50 mm.

5. Preparation of concrete mix.

If you decide to buy ready-made concrete, grades M150‒M200 are suitable. To save money, you will have to dilute the mixture yourself. It is better to take a household concrete mixer from someone, as the material instantly solidifies if it is not in motion.

To make concrete, you need:

- cement M400–M500;

- crushed stone 10–35 mm in size;

- sand with particles 1.2 – 5 mm;

- water.

Table of proportions for the preparation of concrete mix:

The proportion of water can vary from 0.5 to 1 part, depending on the materials. Do not overdo it, otherwise the concrete will lose strength.

For concreting to be successful, it is important to follow the technology from start to finish. There are special additives to improve properties. If you are not using a vibratory compactor, add plasticizers to make the job easier.

6. Concreting.

To properly pour the porch, start concreting from the bottom steps of the stairs. After pouring each step, spread the concrete evenly over the formwork using a stick or vibratory compactor.

7. Demoulding.

Since the concrete will reach its stated strength in 28 days, it is ideal to wait a week after you have poured the structure. If time is running out, leave the mixture for at least 2-3 days.

1. If it is very hot during work, water the concrete every day to prevent cracks.

2. When concreting, it is convenient to use a vibrocompactor. This procedure will give the structure strength, and it will be easier for you to evenly distribute the mixture.

3. Some builders offer to save money by using crushed bricks, broken glass, stones and other debris instead of sand and gravel. If you want to build a porch that falls apart after the first winter, give it a try.

4. It is more convenient for a person to start and end the climb with one foot, so make an odd number of steps.

5. It is better to pour concrete in clear weather, a suitable temperature is +20 degrees.

6. The surface of the steps is equipped with a slope of 5 mm so that water flows freely from them.

7. If you decide to make a semicircular porch, it is convenient to assemble the formwork for the degrees from thin plywood, galvanized.

Finish options

The advantage of a porch made of concrete is a wide choice finishing materials. Economical craftsmen make drawings immediately after concreting using templates or lay out patterns from pebbles, this is inexpensive, but requires attention and patience. There are other options.

- Granite and marble cladding. Looks great and holds up well. Another thing is that a small private house against the backdrop of this splendor can be lost.

- Clinker tiles. Sturdy, non-slip, looks very presentable.

- Porcelain tile. The quality is not inferior to clinker, but it is cheaper.

- Concrete and paving slabs. Inexpensive option, but it gradually crumbles, and slips made by vibrocasting.

- Wood. It is not always reliable, but it looks harmonious with a wooden house.

You can combine several options to create a home-friendly and affordable porch. For example, wood and concrete tiles or granite and ceramic tiles. It is important to choose a reliable material so that its beauty will please you for a long time.

The porch is one of the most important elements of the house. It emphasizes the individuality of the building, gives it a certain style. It is very important for all family members who live in the house that the structure is of the appropriate size, the steps have the same height and width, it is convenient to walk on them.

The following basic requirements are imposed on the construction of the porch of the house: it should be comfortable for walking; have good strength; match the style of the building itself.

The porch can be made of concrete, wood or metal. A concrete structure provides room for imagination: it can be lined with tiles, stone or painted with paint.

A concrete porch can be made built-in, built at the same time as the house, completed after the building was completed.

A concrete structure can be made in the form of: a rectangle, a circle, a square, a trapezoid.

If you want to install a concrete porch with your own hands, you need to follow these rules:

Make the correct waterproofing of the future concrete structure. The structure of the concrete porch should be lower doorway 51 mm, then the door will be easy to open and close. The foundation of the porch is made the same as that of the house - the same depth and through reinforcement. Building materials should be chosen good quality, with good moisture resistance and resistance to temperature extremes.

How to correctly calculate the dimensions of a concrete porch

The main dimensions of the concrete porch are calculated as follows:

- The total height of the concrete porch is calculated from the ground to the threshold.

- According to building standards, the width of the steps is 15 cm larger than the doorway.

- The width of the upper step cannot be less than 100 cm so that two people can fit on it at the same time.

- The height of the steps is made in the range of 12-20 cm. It is made depending on the convenience when walking up the stairs. If elderly people or children live in the house, then the height should not exceed 15 cm.

- Tread must be at least 27 cm wide.

- To correctly calculate the number of steps, you need to divide the total height of the porch by the planned height of one step. If the integer does not work out, then the height of the steps is adjusted so that by multiplying it by the number, the total height of the porch is obtained. The climb will be more convenient if the stairs have an odd number of steps.

- If the concrete porch is made as an extension, then the depth of the platform under it is at least 100 cm.

- The slope of the concrete stairs is done at an angle of 26 ° to 44 °.

- The size of the overhang of steps should not exceed 3 cm.

For the convenience of building a concrete porch, it is best to draw a sketch of it with all distances.

What materials and tools will be needed for construction

After determining the dimensions of the concrete porch, you can begin to calculate the number of building materials. It is better to take materials with a margin, so that later you do not waste time running around for some kilogram of concrete mix.

If the construction is carried out from ready-made concrete, you only need to determine its volume. If you make the mixture yourself, then you need to calculate that to get 1 m³ of concrete you will need: 340 kg of cement, 1 m³ of sand and 0.85 m³ of crushed stone.

To build a concrete porch you will need:

- wooden blocks as stiffeners measuring 4 × 4 cm;

- plywood with boards (2 cm thick and 20 cm wide);

- carnations with large caps;

- reinforcement with a diameter of 7-11 mm;

- wire to create a frame lattice;

- pieces of brick;

- cement and crushed stone, sand;

- material for waterproofing;

- cladding products.

It is necessary to prepare in advance all the tools for construction and check their performance: a hammer drill with nozzles for drilling concrete; concrete mixer; electric saw; vibrator, compacting concrete mixtures; shovels of shovel and bayonet type; spatula, level, tape measure, hammer.

Do-it-yourself steps for installing a concrete porch

Site preparation for construction

The preparation of the construction site consists in cleaning the place where the concrete porch will be located from litter or from the remains of the former porch. After that, a pit is dug with a depth of 20-30 cm lower than the freezing level of the earth in winter period. Holes are made in the foundation of the house for reinforcement to make mutual reinforcement. Too rigid binding of the concrete porch to the house should not be done, since in winter time anyway, the extension will be slightly shifted relative to the main building. If the porch does not have the possibility of movement, then deep cracks will inevitably appear between it and the house.

Then they are engaged in the manufacture of the substrate: a layer of wet sand 15 cm thick is poured onto the ground, a layer of crushed stone 20 cm thick is poured on top, which is compacted into the sand; after, pour another 10 cm of sand; again it is rammed and everything is filled with water. Thanks to this construction technology, the sand and gravel layer will protect the concrete structure from the influence of ground water. A dense film or roofing material is placed on the substrate to prevent the action of water. Then - a reinforcing mesh with cells. And concrete is already poured on top of all this. In order for the air to escape from the mixture, you need to pierce the concrete in several places with a thin stick.

The structure is left to solidify for several days.

Formwork construction

After the pillow has dried, formwork can be made. The frame needs to be strong and rigid to hold the mass of concrete. It is made of plywood and boards, fastened in such a way as to obtain the desired porch design.

The contours of the future concrete porch are drawn on plywood. The risers and treads are made at right angles. After that, a platform is drawn with an upper tread with a slope of 5 mm for every 30 cm for high-quality water flow from concrete surface. The risers are drawn taking into account the inclination of the lower edge inward by 16 °.

Side formwork is fixed with rigid bars. The shields are connected with boards that follow the contours of the risers. A gap of 1 cm is left between the frame and the foundation of the house. Wooden stakes for fixing the frame are driven into the ground to a depth of more than 25 cm. The gap between the frame and the stakes is covered with earth and well compacted.

Before starting the next stage of installation - concreting, the foundation of the house is covered with a patch of roofing material and treated with sealant.

Concreting technology

After completion of the formwork, proceed to the stage of concreting. So that the concrete does not stick to the boards, they are coated from the inside with a lubricant. The entire porch should be concreted at once so that the concrete does not have time to harden. Begins this process from the bottom step. The porch must be filled with tamping the mixture to remove all excess air. This makes the concrete structure strong and durable. For tamping, you can use a special tamping tool, and if not, then a shovel.

In order to save concrete, pieces of bricks or pebbles can be mixed into the solution. So that their pieces do not stick out of the steps, they are leveled with a shovel. The level checks how smooth the surface is, if necessary, it is leveled with a spatula.

Advice ! To strengthen concrete blocks, it is advisable to put on metal corners at the corners of the steps, slightly pressing them into the wet mixture.

The next layer is poured with concrete only after the previous one has hardened. are completing this stage construction by concreting the upper step and the area in front of the door. The finished concrete porch must dry in the formwork for at least 8 days. After that, the formwork is carefully removed so as not to damage the structure. To remove it, it is advisable to tap the boards with a hammer, then they will easily move away from the concrete masonry. The surface of the porch is polished so that there are no protrusions and burrs, as they will interfere with high-quality cladding.

Finishing work - the final stage of construction

Finishing begins to be done no earlier than 4 weeks after the removal of the formwork. The simplest and cheap option to give the concrete porch a finished look - paint it with a special weather-resistant paint.

The lining of small pebbles will look beautiful, creating the illusion of a sea coast.

Advice ! To make the house look organic, the style of the porch decoration should be combined with the facade and roof of the house.

Often a concrete porch is covered with clinker tiles, which are anti-slip and resistant to all weather conditions.

A cladding made of artificial or natural stone. Also good option for a concrete porch there will be a porcelain stoneware coating - a durable and aesthetic material.

If the number of steps is small - 3-4, then the railing is not necessary. But if there are more than 4 of them, it is better to take care of the safety of your household, especially children and the elderly, and make comfortable railings. Properly selected railings can be the highlight of everything country house. They are usually made of stone, metal, less often - of wood. And the best option it will be if the railings are made of the same material as the facing of the steps: the version of the railings and steps made of natural stone will look rich.

In order to create an aesthetic appearance of a country house and a better preservation of the concrete porch, it is necessary to install the canopy. It also needs to be made taking into account the style of the porch and the building itself.