How to properly insulate a steam room and what materials to use. We choose which insulation to use for a bath in a steam room: so that the steam room is hot and environmentally friendly Types of doors and methods for their insulation

One of the most important stages in the construction of a bath is the warming of a steam room, since only a stable temperature regime in this room will achieve excellent performance, as well as a comfortable and beneficial microclimate. Further in the article we will talk about this procedure.

The danger of improper insulation of the steam room

Any errors in the performance of insulation work can lead to a low quality of accepted bathing procedures and a deterioration in the overall performance of the room. Intensive leakage of steam and thermal energy can lead to deformation of finishing materials, to the formation of fungi and mold on them, etc.

In this regard, it is possible to form a set of rules that should be followed when warming the steam bath compartment:

- thermal insulation must be of high quality in everything: correct installation, reliability of materials, etc.;

- the tightness of the floors is very important, since the effectiveness of the procedures depends on the degree of steam conservation in the room;

- in no case should you save on the purchase of thermal insulation materials, since this can lead to their rapid deformation and deterioration of the general visual condition of the steam room in the photo or during visual inspection.

Optimal building materials for steam room insulation

If a we are talking about how to insulate the steam room from the inside, it is immediately worth pointing out the main qualities that the selected materials should have:

- environmental cleanliness without the release of any harmful human body substances;

- high degree of fire safety required for a room where extreme temperatures are reached;

- moisture resistance, which allows you not to be afraid that the material will get wet and become unusable after the first bath procedures.

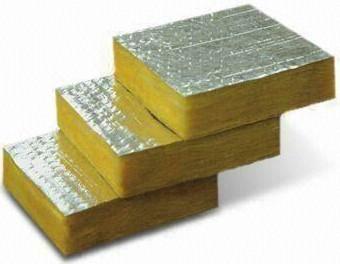

Most of all, all the declared requirements correspond to materials based on basalt. We are talking about stone and mineral wool. The vapor barrier layer in the ceilings can be created from aluminum foil.

It is possible to start laying steam and waterproofing materials, as well as the steam room insulation itself, only after all the wooden floor elements have been treated with antiseptic agents. It is always worth remembering that floors contain more than one layer of material and thermal insulation is not the crown of the whole structure. In fact, the walls and floor are sandwiches, in which each layer is responsible for certain functions.

Proper drafting of the bath project is the key to success

In addition to carrying out the warming of the steam room in wooden bath, it is necessary to create a competent project of the entire structure.

When developing a project, the following parameters should be taken as a basis:

- To begin with, it is worth deciding on the size of the bath. For this, the maximum capacity of visitors and the number of rooms that are planned to be equipped inside the building are taken into account.

- The project itself is created with an emphasis on taking into account all possible losses thermal energy and their minimization. For example, the dressing room is located at the exit from the bathhouse in order to minimize the access of cold air masses to the main part of the building where the steam room is located.

- Between the washing room and the steam room, a vestibule should be equipped, which will not allow steam to leak into a room with a lower temperature.

- The door in the steam room should not be large, but its joint with the floor should be raised with a special threshold, which does not allow cold air to enter the room.

- The greatest convenience of the steam room is achieved when the room has the shape of a square. One of its corners is reserved for installation heating furnace. It is desirable that this be the corner closest to the front door.

Also, do not forget that when designing it is necessary to determine the materials used. If we are talking about how to insulate a steam room in a bath, then artificial or natural materials can be used.

Natural materials are the following types:

- tow - used to seal cracks that are formed during the creation log cabin or buildings from wooden beams;

- sphagnum - is laid between the crowns;

- construction moss is a standard wall insulation.

If the warming of the steam room in the bath is made with artificial materials, then we are talking about the following varieties:

- extruded polystyrene foam;

- mats made of stone or mineral wool.

Each of these materials has a long service life, a high level of mechanical stability, moisture resistance, etc.

The importance of insulating ceilings in the steam room

The ceiling has a greater amount of insulation material compared to wall ceilings. The reason for this is the convection of air: when heated, it rises to the ceiling, and cold air descends in its place. The same thing happens with water vapor. Concerning thermal insulation materials in the ceilings are laid in two layers, which will reduce the level of heat loss.

Ceiling thermal insulation of the steam room of the bath is carried out in stages:

- The rough surface of the ceiling is covered with paper in rolls. The sheets are overlapped with each other with a sufficient spade. Sheets are fixed with wood blocks measuring 5x5 centimeters.

- Empty spaces between the bars are laid with heat-insulating material.

- Then all segments of the ceiling are covered with aluminum foil, which is fixed with adhesive tape. It is important to avoid the formation of gaps and cracks in this layer. It is the foil surface that maximizes the safety of water vapor in the steam room and prevents condensation from forming. In the absence of aluminum foil, the ceiling of the bath steam room can be insulated with paper or cardboard impregnated with special compounds. It is worth finding out in advance how to insulate the ceiling in the bath is best in your case.

- From above, the coating is once again lined with bars measuring 2x3 centimeters. This improves the ventilation of the ceiling.

- On top of these bars, the selected facing material is mounted.

Features of steam room wall insulation

After the ceiling has been insulated in the steam room, you can begin to process the walls. The rough surface must be specially prepared for this procedure. Any joints, cracks and other cavities must be plastered or sealed with sealant.

- First, aluminum foil is fixed with wooden blocks 4x4 centimeters in size, placed horizontally.

- Thermal insulation material is laid between the bars.

- Then the foil is finally fixed with a construction stapler. It is important to stretch the material, but not to allow the formation of gaps, cracks or tears in the foil.

- All joints of the structure are glued with a special aluminum tape.

- On top of the tape, bars are longitudinally attached for laying the selected facing material.

- The work is completed by laying the finish coat.

When finishing, materials of low density should be used, since the insulation of the steam room in the bath requires the main thing from all structural elements - to keep the heat in the room. It is best to pay attention to materials from pine, linden or aspen wood with a small thickness of the planks. They not only reliably protect the steam room from heat loss, but will also look aesthetically pleasing in the photo and during visual inspection.

The installation of the material should be carried out in a horizontal way in order to reduce the total load distributed over the main structural elements. Penofol, which is gaining its popularity in the construction market, should be chosen as a warming material.

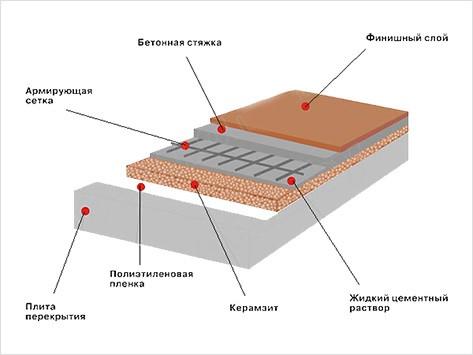

How to insulate a concrete floor in a steam room

In the end, you should move on to warming the floors in the steam room. In addition to thermal insulation, you should also take care of waterproofing floors. There are two types of materials mounting algorithm. AT this paragraph we will talk about floor insulation in a steam room with a concrete base.

The following algorithm for heat and waterproofing is simplified, as it is used when laying under a tile.

Work is carried out as follows:

- The base is leveled to a perfectly flat state.

- Bituminous mastic is applied on top of it and it is expected to dry completely.

- Then roofing material and a polymer film are laid.

- Top Mounted tile(read: "").

Better construction for concrete floor insulation:

- A plywood sheet is mounted on a draft base.

- A waterproofing layer is laid on it with a spade on the walls.

- All joints are glued with aluminum tape.

- The gaps are sealed and insulated with a building hair dryer.

- A reinforcing mesh is laid on the layer and poured with a layer of concrete mortar.

- After the screed hardens, you can begin laying the tiles.

When pouring concrete screed it is important to take into account the age of the wood used to create the chopped bath. It is important to use material from the age of 2 years. Otherwise, the structure will shrink, which will cause deformation or destruction of the foundation.

Working with a wooden base

Work is carried out as follows:

- Mineral wool is laid under the logs.

- A rolled roofing material is laid on it.

- All wooden elements in the floor structure are treated with special antiseptic agents.

- A subfloor is laid on the roofing material.

- The work is completed by finishing the surface with a finishing floor covering.

After the insulation for the steam room is embedded in the floor from the inside, the “pie” of the floor looks like this:

- foundation;

- wooden beams;

- vapor barrier material;

- lining and heat-insulating material;

- floor board.

Also, in the process of laying the floors, you need to take care of creating a high threshold under the front door. This is the most important functional measure aimed at protecting the steam room from cold air masses entering it. Naturally, the complete preservation of water vapor inside the room can only be ensured when the door leaf is as close as possible to the frame and sill.

We must not forget that a separate area in the room should be allocated for the installation of the furnace and the subsequent chimney outlet. A separate foundation base is mounted under the furnace with a height greater than that of the main foundation.

When equipping the walls and ceiling, it must be taken into account that a chimney will exit through one of the ceilings, for which a square hole will have to be cut out and a frame equipped in it. Regulations require that the chimney from the stove be placed at least 20 centimeters from any wooden elements in the structure of the bath. This hole is closed with a stainless steel sheet.

Outcome

The article describes in detail the procedure for insulating walls, floors and ceilings in the steam bath compartments. It is important to take into account all the recommendations and advice given in the article, as well as pay special attention to the standards for conducting construction works, since installation errors can lead to an unfavorable outcome.

Also, the work can be entrusted to specialists who will take responsibility for all stages - from procurement necessary materials before installation and commissioning of the bath.

The internal insulation of the bath is one of the most important stages in the arrangement of this building. Without high-quality thermal insulation, the owner will have to spend much more resources on heating the steam room, and the very situation in the bath without properly installed protection will leave much to be desired.

Since ancient times in Russia, moss, felt and even flax have been used to insulate baths, mainly due to the lack of other heaters - vegetable fiber either rots or dries, therefore today it is not used for basic thermal insulation.

Red moss - insulation

The main difference between warming a bath and a similar event in an ordinary house is simple: in the steam room you need to keep the heat for as long as possible, i.e. high temperatures should remain indoors for as long as possible.

Thermal insulation work in the bath can be carried out using a wide variety of materials. For example, the ideal solution is a modern insulation based on stone wool with applied foil coating - it does not burn, withstanding temperatures up to 750 degrees, effectively retains heat, does not rot, is of no interest to rodents.

After reviewing the information below, you will get a complete theoretical understanding of the process of performing internal insulation of a steam room, and also study step by step instructions for independent installation of thermal insulation materials.

Any construction, repair and finishing activities begin with the preparation of materials, without which the implementation of the planned work will simply be impossible. Pay due attention to the study of the list below: it is better to spend a little time reading and buy everything you need right away than to return to the store and buy more of what you forgot.

insulation

The main component of the list under consideration. The modern market offers the widest range of thermal insulation materials, but not every one of them is suitable for use in a steam room - humidity and temperature can be too tough. For warming the bath, the most commonly used are: expanded clay (floor insulation), materials based on stone wool, and expanded polystyrene.

Important! It is strongly not recommended to use foam plastic for warming the steam room directly - at high temperatures, a material of dubious quality can most likely release substances harmful to human health.

Comparative characteristics of the mentioned materials are given in the following table.

Table. Comparison of popular bath heaters

| Evaluation criterion | |||

|---|---|---|---|

| Structure | bulk material natural origin. Presented in the form of granules with a cellular structure. | fibrous structure. The arrangement of fibers is both vertical and horizontal, disordered. | Open cell structure. |

| moisture permeability | The material does not pass water. | Mineral wool insulation has practically no tendency to absorb moisture. | Moisture permeability is extremely low. |

| The weight | Easy | Medium-light | Easy |

| Strength | high | Medium | Medium |

| Compressive strength | high | From low to medium, depending on the specific type of material and manufacturer's technologies. | Medium |

| Toxicity | The material is safe | No toxic properties | Over time, it begins to release harmful substances |

| Can be used under high load conditions | Suitable | Depending on the brand of material | not suitable |

| prone to decay | The material retains its original integrity for a long time | Durable insulation | Has a tendency to break down |

| UV resistance | Doesn't react to sunlight | Features high UV resistance | Long-term direct contact with sunlight has an extremely negative effect on the performance of the material. |

As noted, expanded clay is suitable for warming bath floors. Bulk material allows you to provide the required thermal insulation of both wooden and concrete structures. Mineral wool insulation is optimally suited for insulating both walls and ceilings. The best option, as noted, is a heat-insulating material based on stone wool, equipped with an additional foil coating - the key characteristics of such heaters at a higher level.

Mineral wool prices

mineral wool

In accordance with the current provisions of the technology for carrying out the work in question, the joints of the insulation boards must be glued with foil tape. This will create a sealed surface with the highest possible thermal insulation properties.

foil tape prices

foil tape

The elements of the heat-insulating coating are placed in the cells of a pre-mounted crate, for the assembly of which are used wooden blocks. Select the cross section of the bars in accordance with the thickness of the thermal insulation. For example, if you are equipping a 10 cm thermal insulation layer, use bars with a similar thickness or width to assemble the frame.

Choose the distance between the bars 1-2 cm less than the width of the plates or the insulation roll. For bulk materials, the optimal distance between the bars is 45-60 cm.

Fixing the elements of the crate (bars) is carried out using dowels / self-tapping screws (if the surface is wooden) or anchors (if the base is stone). The length of the fasteners is also selected in accordance with the base material: for wood - 2-2.5 cm, for capital structures - from 4 cm.

The specific length of fasteners is determined in accordance with the characteristics of their use. For example, during the installation of the crate, the fasteners must be of such length that high-quality fixation of the timber / profile of the selected section is ensured. The cross section of the beam itself, as well as the profile parameters, are determined in accordance with the thickness of the heat-insulating layer to be equipped.

Additional materials

If the bath is insulated with a material other than foil mineral wool, you will additionally have to purchase a hydro-vapor barrier film.

If a concrete screed is planned to be poured, the work set will increase to include the items listed below:

- reinforcing mesh;

- mixture for pouring the screed or materials for its self-preparation (cement, sand, water);

- lighthouses;

- damper tape;

- polyethylene.

Prices for waterproofing film

hydro vapor barrier film

The floors in the bath can be wooden or concrete. The technology for arranging the heat-insulating layer directly does not have any special differences depending on the floor material, except in the case of concrete structure you will have to pour more expanded clay.

The thickness of the backfill is usually determined in accordance with the thickness of the walls. On average, a layer of expanded clay is poured at least 2 times thicker than the walls. If the height of the room allows, the thickness of the backfill can be further increased - this will help increase the efficiency of insulation.

Previously, for greater convenience of work and subsequently more accurate control of the evenness of the backfill, mark the base. To do this, it is enough to divide it with parallel lines into sections up to 1 m wide or along the length of the rule you use.

Important! If you are insulating the floor on the ground, at the very beginning, even before marking, you must do the following:

- carefully tamp the ground inside the base (if the foundation design assumes the presence of “free” soil, for example, in the case of strip supports);

- cover the walls with impregnation for waterproofing;

- fill the soil with a 10-centimeter layer of sand, spill it with water and carefully tamp;

- cover the sand with roofing material with a 15-centimeter overlap on the walls. Lay individual sheets of roofing material also with a 15 cm overlap. For fastening, use waterproof construction tape.

Directly the procedure for warming the floor with expanded clay with illustrations and the necessary explanations is given in the following table.

Table. Bath floor insulation with expanded clay

| Stage | Illustration | Necessary explanations |

|---|---|---|

| The film must be stretched so that its edges along the wall are above the floor level. If the base is already covered with roofing material, there is no need to lay the film. |

|

| For example, a profile for drywall is well suited. The guides are set in accordance with the previously applied markings and fixed in a suitable way, for example, screws or nails. | |

| Set the beacons according to the level. In the future, these accessories will help you fill the most even layer of expanded clay, which will ensure best quality execution of further planned activities. Determine the installation height of the guides in accordance with the required thickness of the heat-insulating layer. Many developers do without guides, but this is a less convenient and accurate option. |

|

| We pour expanded clay |

| The previously installed guides will help to do this as efficiently as possible. |

| For leveling, we use a rule or an ordinary rail of a suitable length. | |

| For greater convenience of leveling the insulation, we can use various auxiliary devices. For example, in large areas, a rake will come in handy. |

The floor is insulated and ready for further development in accordance with the developer's plans. At the discretion of the owner, additional heat-insulating material, for example, mineral wool or expanded polystyrene, can be laid on top of expanded clay.

As an example, a diagram of a concrete floor, equipped with expanded clay for thermal insulation, is given.

Video - Floor insulation with expanded clay

Insulation of bath walls and ceiling

Wall insulation schemes will vary somewhat depending on the material of manufacture. Information about this is presented in the following table.

Table. Wall insulation schemes

| Production material | Scheme |

|---|---|

|

|

1 - wall, 2 - thermal insulation, 3 - lathing, 4 - sheathing, 5 - ventilation gap. |

|

|

The sequence of thermal insulation work remains the same for walls made of any materials: if necessary, a hydrovapor barrier film is attached, lathing bars are mounted, insulation is placed in the formed cells, another layer of hydrovapor barrier is fixed on top (if necessary), lathing laths are nailed for finishing sheathing (at the same time they will provide the necessary ventilation gap), the selected finishing material is mounted (usually lining).

The ceiling is insulated in a similar sequence. An example of a ceiling thermal insulation scheme is shown in the following image.

Information regarding step-by-step warming walls and ceiling of the bath is shown in the following table.

Important! Insulation will be carried out with a mineral wool material with a foil layer, which eliminates the need for preliminary fastening of a hydrovapor barrier material to the surface. The order of work is considered on the example of wooden surfaces. In a relationship concrete walls and ceilings, the recommendations are the same, the only thing is that you need to use other fasteners and for greater convenience, wooden guides can be replaced with a metal profile.

Table. The procedure for insulating walls and ceilings in the bath from the inside

| Stage of work | Illustration | Necessary explanations |

|---|---|---|

| Information regarding the elements used to arrange the frame, as well as fasteners for fixing the guides in different occasions cited earlier. The installation step of the guides is selected in accordance with the width of the insulation. As a standard, this is about 60 cm, it can be reduced to 59-59.5 cm so that the heat-insulating elements lie as tightly as possible. |

|

| Slab laying rules |

| We must first put on gloves - the contact of “bare” skin with mineral wool does not deliver the most pleasant sensations. The foil material is laid with foil inside the room - thanks to this, the heat will not only be retained, but also additionally reflected into the steam room. |

| The slabs are installed by surprise into the frame and do not require additional mechanical fastening. | |

| Installation of plates on the wall |

Installation of plates on the wall | The sequence and recommendations for wall and ceiling insulation are similar. To insulate the partition separating the steam room from the adjacent room, a layer 50 mm thick is usually sufficient. |

| The thermal insulation of the outer wall requires a thicker layer - 100-150 mm (in regions with a particularly cold climate - up to 200 mm). | |

| In order to save money, the insulation can be made two-layer, equipping one layer of ordinary mineral wool, and the second, which will “look” into the room, from a foil-coated material. | |

| The use of such a heater, as noted, eliminates the need for additional waterproofing materials. |

|

| Having filled the frame with heat-insulating plates, we glue the seams and joints with foil tape. | |

| A 1-2 cm gap is enough. The outer trim will be attached to the same crate in the future. Important! The order of further installation of the lining depends on the location of the rails: if the rails are fixed vertically, the lining must be fixed horizontally, and vice versa. |

|

| The best material for the interior lining of the bath is lining. The choice of material for the manufacture of the skin is at the discretion of the owner. The fixing of the cladding elements is traditionally performed using screws / self-tapping screws. |

Video - Insulation of walls and ceiling from the inside

Now you know everything about how to properly insulate a bath with your own hands using the most optimal heat-insulating materials for this. The information obtained will help you cope with the planned events on your own, eliminating the need to contact third-party masters and saving significantly.

Successful work!

Video - Insulation of the bath from the inside scheme

A good heater for a bath is the most important thing to pay attention to when it comes to interior design. After all, the safety of bathing procedures, their comfort, and the durability of the walls themselves directly depend on its quality - especially in the steam room. But how to figure out which insulation is better for a bath, when almost a dozen of their types are offered on the modern market? Our article will help you with this.

So, back in Soviet times, civil engineers made the following discovery: any homogeneous thick wall does not guarantee effective heat retention - because it will necessarily absorb some of the energy itself. But a multilayer structure, in which materials of different technical characteristics are located - in terms of density, porosity and thermal conductivity - just well prevents heat loss, and such a half-meter "pie" can be compared in its performance with a wall one and a half meters thick. But the effectiveness of the "pie" itself depends on what kind of insulation for the bath was chosen.

Requirements for a bath heater

First of all, it is environmentally friendly, most resistant to moisture, well resistant to the growth of bacteria and fungi, and, finally, able to keep its shape well for many years. And the most important indicator of the effectiveness of a heater is the coefficient of its thermal conductivity. The higher it is, the better the material itself. For example, it is mineral wool that is considered the warmest so far - its indicator is 0.045 W / (K * m).

In addition, there are additional requirements for the heater in the bath:

- It should work well with existing finishing and building materials without affecting their specific benefits in any way.

- Do not allow condensation to accumulate.

- Have the lowest moisture absorption value.

- Have a certificate of safety of use and full compliance with fire and sanitary and hygienic criteria.

- Ensure the possibility of performing absolutely hermetic thermal insulation.

organic heaters

These are heaters that are made from plant or animal material - linen tow, shavings, cellulose, felt and others.

For example, heat-insulating products made from peat, reeds and woodworking waste are quite popular today. These are reed, chipboard and peat slabs, which are good for warming the dressing room and the rest room. They are not allowed in hot rooms - despite the fact that such materials are usually additionally treated with flame retardants.

Inorganic heaters

Such heaters are made through the processing of minerals. And they are already divided into:

Polymer heaters and their features

Polymer insulation includes all those that are created by human hands - first of all, it is polystyrene. This material is like a heater for, if it has a second floor, it is light, convenient and practical. It is easy for them to carry out all the work, it resists moisture well and tolerates high temperatures.

These types of this material are most often used today for insulation: foam plastics, foam plastics with a foamy and cellular structure, honeycomb plastic insulation. The newest and quite popular option today is foam glass, which is easy to cut with a knife and saw, and conveniently attached to the surface. In addition, foam glass as a heater for the roof of the bath embodied all the best from stone wool and polystyrene.

But still, it is extremely undesirable to insulate the inside of the bath with polystyrene - due to the fact that at high temperatures it begins to emit dangerous vapors of phenol, a particularly toxic substance. After all, only perfectly chemically pure materials can be used for a bath - and absolutely fireproof.

Mineral and glass wool insulation

This includes the famous mineral wool and not only. In general, mineral heaters are considered the most economical for baths. They are made from stone and slag fibers, so that such mats can even be used to insulate the surface of a bath pool.

But basalt insulation for a bath, diabase, dolomite, slag and limestone wool has its own priorities in that they are not combustible, have really high insulating characteristics, are durable, do not deform and are famous for their water-repellent properties. Installation with such cotton wool is quite simple and convenient, and the material itself is not to the taste of rodents. That is why basalt and stone insulation for a bath is one of the most preferred today.

Close in its characteristics to basalt wool and glass wool - it is also more flexible in installation. However, the limit of resistance to high-temperature exposure is lower. As a heater for the walls of the bath, it fits well - but not for the steam room.

Benefits of foil insulation

Insulation for the ceiling in the bath is most often selected with reflective characteristics. Among them, the so-called mirror heaters are quite popular today - they are supplemented with a special polished aluminum film that does not let the most valuable - infrared thermal radiation - pass outside the steam room. And such a “pie” is much more effective than ordinary foil on cotton wool, which is often simply not able to withstand massive heat loss. In fact, this is an ideal heater for the ceiling of the bath, and not only.

What kind of insulation to take for insulation between the crowns?

Insulation for baths and saunas can be not only internal or external, but also interventional. Indeed, the heat in the bath itself depends on how densely the space between the logs is filled.

So, for a long time, materials such as red moss, cuckoo flax, sphagnum, woolen felt, hemp hemp, linen tow and jute were used to insulate the log house of the bath. But all of them are very attractive to birds and insects, and therefore, already a couple of years after the insulation, it is necessary to restore the thermal layer between the logs. In addition, if such an interventional insulation also turns out to be underdried, then it will begin to rot and simply pull the entire log house with it.

It is quite difficult to work with such materials - they quickly dry out during the masonry process, and therefore it takes just a lot of time for all this. That is why today builders increasingly prefer new hybrid heat insulators - combinations of jute and flax fibers. These are lnovatin, flax-jute felt, jute felt and fluffy spruce or pine wood. All of them fill the gaps in the log house well and do not require re-caulking.

However, for each type of bath, or rather, the material from which it is built, its own type of insulation is suitable. About what on our site there is a separate interesting article.

Comfortable living is provided not only by the availability of utilities and the design of the premises. It is important to protect the house from heat loss, which is important in the cold season. Doors and windows are powerful sources of penetration into the house of cold air masses. There are several ways to keep the heat in the room.

Change doors to energy-saving designs. This is not cheap and is associated with accompanying operations for the design of slopes, the installation of platbands, and so on. In many cases, it is possible to solve this problem in affordable ways without significant costs. One of the traditional insulation materials is a felt door seal, which has both disadvantages and advantages.

Advantages of felt seals

Today, manufacturers offer a new generation of materials that are easy to install and affordable. The share of felt products is decreasing, but it is too early to abandon the use, since they have a number of special qualities:

- Wear resistance. Natural fibers withstand significant physical exertion without compromising quality.

- Life time. Unlike rubber and foam rubber seals, felt does not contain volatile substances, the content of which steadily decreases during operation. This leads to the destruction of the material and requires replacement. Felt seals do not lose their properties for many years.

- Soundproofing. The material absorbs vibrations. Both postorennye noises and the sounds of the door in contact with the box are extinguished.

- Environmental friendliness. Only natural raw materials are used in production. There is no emission of substances harmful to health.

- Fire safety. The density of wool fibers and their qualities are such that combustion is impossible under normal conditions.

Finished felt seal for doors

Disadvantages of felt seals

Previously, felt as a heater and sealant was used everywhere. It was considered the best material for these purposes. Why is this method of protecting housing from the cold inferior to primacy? Despite the fact that the user qualities of felt are not in doubt, there are also disadvantages:

- Price. Production refers to traditional technologies with a long history. Felt is made from natural wool. In the process of hydrothermal processing, the fibers are pressed into a sheet or roll material. The cost of raw materials and wages form a price that is higher than a synthetic fiber of a similar area.

- Difficulty of installation. On sale it is difficult to find a felt seal that meets most of the requirements. All operations require an individual approach and qualifications. The range of felt materials is limited. It is necessary to independently cut the strips of the required width and choose the method of fixation.

Roll felt

Roll felt

- Attractive to moths and mice. Unlike microorganisms and molds that do not live in felt, rodents and some types of insects like the material. Moth perceives felt as a food product, and mice insulate their minks with it.

Attention! When buying, you should carefully read the information about the product on the packaging or in the accompanying documents. Natural felt is 100% wool. There are materials with a similar name on sale, but they cannot be considered as such. In cases where the percentage of natural fiber content is indicated in the composition, and even more so when it is absent there.

Types of felt seals

The production of the material is localized in the regions traditionally producing wool products. Classical technology is rooted in the distant past and has secrets. Not all developed countries know how to make felt. In Russia, the secrets of production are not lost, and the products enjoy well-deserved respect. Despite the fact that the manufacturing process is traditional, product quality is regulated by state standards. The consumer can choose the necessary felt of the following types:

- GOST 288-72. Fine-wool technical felt. The inclusion of synthetic substances is allowed. The main application was found in technology. Gaskets, seals made of this material are used in mechanical engineering;

- GOST 6308-71. Semi-coarse technical felt. Excellent wear resistance. It is used in mechanical engineering and in small volumes in construction;

- GOST 6418-81. Coarse-wool technical felt. It is used in many areas of economic activity. From mechanical engineering to construction;

- GOST 16221-79. This type of felt is called yurt felt. The name corresponds to the purpose of the material. Produced in the form of rectangular cavities. single standard no. Allowed length from 2 to 6 m, and width from 1.4 to 2 m;

- Felt. It is used for technical purposes and in the production of household items and clothing. An expensive kind of felt. Produced in thicknesses from 2 to 10 mm. Felt seal is made from old things, such as hats or anti-shock layer removed from packages, which is used to transport fragile valuable instruments and devices.

Automotive Soundproofing Felt

Automotive Soundproofing Felt

Any felt is used as a door seal. The minimum required thickness must be taken into account. The dynamic compression ratio of felt is limited. For this reason, the difference in the width of the gap should not exceed 2-3 mm. Otherwise pretend door leaf will not be tight, the seal will be partial and the protection will not be effective.

Advice! With an uneven gap width, you can pre-fill places with a large gap with pieces of felt of the desired thickness. It is easily cut in the longitudinal direction. After preliminary alignment, the finishing strip of felt is installed. Another option involves mounting the felt seal with the end side relative to the plane of the door. It is effective in this case to form a roller.

How to fasten felt

When this type of seal was used everywhere, and there was no alternative, it was nailed. Decades have passed since then, and there are more ways to fix. Easy to use stapler. A paperclip is better than a nail at holding material. But the traditional method of fastening with decorative nails has not lost its relevance. Video showing how in a simple and affordable way you can seal the door porch yourself

A wide range of adhesives allows you to choose a brand for fixing both wood and metal surfaces. You can’t fix felt on a steel sheet with nails or a stapler, so in this case it is best option. Double sided tape is not recommended. It can be used in exceptional or emergency cases. The strength of the connection is low and the service life will leave much to be desired.

Universal adhesive "Nairit" indicating the application for felt

Universal adhesive "Nairit" indicating the application for felt

The glue method has nuances. The loose and fibrous structure of the felt requires a large amount of composition. Ground layer recommended. The prepared strip of insulation is smeared with glue and allowed to dry. It's not worth doing too much. Enough impregnation to a depth of 1 mm. After complete drying, a layer of glue is applied, and gluing is carried out according to the technology recommended by the manufacturer in the prescribed mode.

colored felt

colored felt

In some cases, felt insulation is used specifically to maintain a folk style. In wooden houses, baths with deliberately rough surfaces, natural material looks organic, and designers are happy to use this technique. The fiber dyeing technology has been worked out, and today felt can be purchased in a wide range of colors.

Felt seal for doors: protecting the house from the cold

Felt seal for doors: what types of material are best suited for this. Mounting technology. The nuances of installation on various designs doors.

What is the insulation for the door - briefly about the main

Doors are not only the "face" of any home and reliable protection against uninvited guests, but also a barrier against drafts and cold entering the room. However, even a new door leaf often does not cope with this task up to the mark. For this purpose, door insulation is used. It is also needed to isolate the room from sounds coming from outside.

Features of the choice of door insulation

The reasons for heat loss are different: from skewed door leaf and insufficient sealing, to insufficient quality of the material. If replacing the door is not included in the plans, then the only right solution that will help save 25-30% of heat energy is door insulation, the nuances of which will be discussed.

In order to reliably insulate the entrance or balcony doors, use the following materials: mineral wool; cellular insulation; liquid insulation; polypropylene; felt insulation (including self-adhesive); polyurethane, anti-draught.

The nuances of installing door insulation

You will have to tinker with the insulation of a metal door.

Algorithm for mounting insulation on a metal door:

- If the door is collapsible, it is unwound, having previously removed it from the hinges and dismantled the locks with handles. In the case of welded seams, they are separated using an angle grinder.

- Laying the insulation in an empty box (if necessary - blowing with mounting foam).

- Assembly of the door frame.

In the case of a wooden door, the jamb is first leveled and the hinges are strengthened.

Stages of fixing insulation on a wooden door:

- The doors are removed from the hinges, the fittings are untwisted.

- The canvas is laid on a flat surface, after which a heater is attached to it with liquid nails or glue.

- The upholstery is reinforced with an interval between nails of 30 cm.

Each material has design and installation criteria that help you choose the right insulation.

Mineral wool

Mineral wool is produced from silicate rocks. High noise and heat insulation characteristics of the product are determined by the fibrous structure. Mineral wool is environmentally friendly, non-flammable, resistant to moisture penetration, the influence of temperature fluctuations, is not afraid of chemicals, and is also characterized by moderate cost.

The main disadvantages of the material are subsidence under its own weight, resulting in the formation of voids. To avoid this, the installation of additional stiffeners that can keep the insulation from slipping helps.

Cotton wool is applied to the entire surface of the door leaf, avoiding gaps, using glue or fasteners, paying attention to insulation around the perimeter. From above it is covered with a decorative coating (leatherette).

Today, this method of door insulation is rarely used in practice due to moral and technological obsolescence.

The cost of the material is from 385 rubles. for packing and more. Mineral wool without a binder costs from 35 r. for 1 kg.

Honeycomb insulation

This material is essentially a standard cardboard, factory pressed into an accordion or in the form of a honeycomb.

Honeycomb door filling is considered the cheapest option for insulation, but the least effective in terms of insulation from noise or cold air. It is used as a filler, which deprives the door of hollowness.

Mounted as standard, on the entire surface of the door, avoiding obvious gaps.

The cost of the material is from 29 to 125 r per 1 sheet. If you purchase material in a roll, then the price is 2100-3800 rubles.

Liquid insulation

Liquid insulators are considered an alternative to frame bulky heaters. They are a mixture similar in consistency to paint, but with the following useful properties:

- high level of thermal conductivity, sound insulation (1 layer of liquid insulation corresponds to a layer of mineral wool 50 cm thick and helps to save 30-40% of thermal energy);

- immunity to fire, UV radiation;

- ease of application.

The disadvantage of such materials is considered not to everyone the affordable cost and many fakes on the market.

Liquid insulation is applied with a roller or brush, like paint, after sealing the cracks in the door leaf.

The price for 1 liter of liquid insulator is from 260 rubles. and higher, depending on the brand and technological nuances of the mixture.

Foam propylene

The main advantages of this insulation are environmental friendliness, light weight, insulating characteristics, resistance to fire, moisture, chemicals and atmospheric phenomena. Penopropylene withstands loads, does not absorb water.

It is produced in the form of air plates that can be easily cut to the required dimensions and easily attached to the door using special glue or liquid nails.

The material costs starting from 1100 r and above for 1 package, which differ in size or number of sheets.

felt insulation

It is considered a classic option for insulating the door leaf. Traditionally, a felt seal is used, but now a self-adhesive insulation for doors has appeared.

Self-adhesive felt insulation for doors or foam rubber is attached to the pre-cleaned door leaf around the perimeter. At the same time, make sure that the material does not interfere with the tight closing of the door and seals all the cracks.

Self-adhesive for doors costs starting from 30 rubles. per 1 roll, depending on the length and manufacturer of the product.

polyurethane foam

This strong and durable material is a mixture of bubbles, which has anti-noise and heat transfer characteristics, is not afraid of moisture, fire and chemicals. Differs in good adhesion with a surface, does not demand preliminary processing of a cloth. PPU is available in elastic or rigid form.

Liquid PPU is pumped into the door frame with a gun and covers the entire canvas with an even layer. After drying, all gaps are additionally filled in and the surface is cleaned, preparing it for sheathing.

Self-assembly presents certain difficulties and requires practical experience.

Sheet polyurethane foam costs starting from 734 r per 1 pc.

anti draft

This insulation is attached to the bottom of the door, due to which the gap between the floor is isolated, protecting the room from drafts.

Mounted easily, according to the factory instructions. Cost - from 90 rubles. for 1 piece 85 cm long. right choice insulation will help experienced professionals.

Door insulation (self-adhesive and felt): find out how to choose

However, even a new door leaf often does not cope with this task up to the mark. For this purpose, door insulation is used.

How and what to insulate the door

Insulation of entrance doors is relevant both for a private house and for an apartment in a multi-storey building, since heat loss through a doorway in the cold season can reach up to 20%. The easiest and cheapest way to eliminate drafts is to fix the door insulation in problem areas of the opening. The traditional material for creating a barrier to the penetration of cold air into housing is ordinary building felt, but besides it, there are a lot of modern synthetic insulation, and about the whole variety of these materials - below.

Felt tape for insulation of doorways

Felt tape for insulation of doorways

Types of doors and methods of their insulation

No matter how tightly the doors are fitted to the frame, over time, gaps appear between the door leaf and the frame, and the frame itself may warp. Therefore, the factory seal is broken, allowing cold air to freely enter the living areas of the house. Completely changing the door is a costly and not always acceptable solution, and fixing felt insulation on the ends of the door or opening is a cheap and quick solution, which often completely eliminates blowing through the door. But, besides the time factor, there are other reasons for the occurrence of a draft in the front door opening:

- Erroneous installation, mismatched door leaf;

- Loosening of canopies (loops);

- The old house has crooked walls.

Removing drafts from the front door

Removing drafts from the front door

The door leaf and frame made of wood warp and wear out much more often than metal structures, since the tree absorbs moisture well, and it is not always possible to protect it from this qualitatively. Due to soaking in moisture, cracks and twisting of the fibers appear in the wood, and such deformations are potential places for drafts to enter. Due to periodic moistening and shrinkage, doors can sag, loosen, dry out, crack and deform, which will necessarily affect the density of contact between the leaf and the frame.

Therefore, wooden doors are not installed as often as before, and this is facilitated by the appearance of doors made of other, more modern and reliable materials - plastic, metal, glass, or a combination of these components.

Metal entrance doors are the most reliable and warm, despite the fact that metal conducts heat well. The fact is that a high-quality insulation is laid inside the fabric structure, and often this is a felt seal or synthetic materials such as foam, polypropylene or synthetic wool. Besides, high accuracy the manufacturing of the structure ensures minimal gaps between the door and the frame, which means that the insulating gasket will be dense and durable. Price metal doors higher than wooden structures, but their reliability is much higher. The same applies to doors made of plastic or glass.

Internal organization metal doors with insulation

Internal organization metal doors with insulation

The designs of wooden doors are made of solid wood, from a panel assembly, with a glued or paneled canvas.

Of all the listed designs of entrance doors, plastic ones withstand sub-zero temperatures worse than others and poorly retain cold air flows. Therefore, to insulate plastic doors, you will have to try, and the best way out is to hire a specialist. But the most reliable, albeit expensive option is to install a second front door. However, it, like the first door, will also have to be insulated.

And, if for the installation of at least the first, at least the second entrance door, the help of professionals is needed, then to attach a felt seal to the door, you only need your desire. When carrying out this simple operation, you first need to check the box (door frame), canvas, fittings, lock, and even platbands for their proper fastening, the absence of cracks and loosening. To prevent such an examination from giving negative results, it is recommended to regularly carry out the following set of measures:

- Seasonal preventive maintenance: lubrication of moving mechanisms (except for the lock secret), checking fasteners, replacing hinges, etc.;

- Elimination of subsidence or sagging of the canvas;

- Wooden doors must be coated with varnish, paint, water-repellent impregnation, and the coating must be renewed annually;

- Checking the strength of the fastening of the door frame, if necessary - its additional strengthening;

- Check existing insulation, if necessary - install felt insulation for doors.

Freezing points and places of insulation

Freezing points and places of insulation

Materials for door insulation

The functional range of materials that create a hermetic seal between the door leaf and the box, prevent the penetration of moisture and cold air currents from the street, is quite wide, but traditionally these are: polyethylene foam), rubber tape seals. To insulate the gaps, it is recommended to use synthetic seals that do not collapse from temperature extremes and moisture, and to insulate the door leaf, it is preferable to mount natural materials from felt, felt, etc. Such thermal insulation will be protected from harmful atmospheric influences by the door body.

Since insulation can be combined with decorating the canvas, leatherette or synthetic leather with a layer of insulation is best suited for this purpose. natural Decoration Materials – expensive pleasure, and they are usually ordered individually. For self-insulation of the door you will need:

- Thick fishing line or soft thin wire;

- Screwdrivers, screwdriver and screws (for wood or metal - depends on the material of the door);

- Bit for a screwdriver or drill to make grooves in a wooden sheet for sealing tape. In such grooves, you can insert felt insulation, synthetic winterizer, soft rubber, foam rubber;

- Mounting construction foam for sealing the gaps between the box and the wall of the entrance doorway;

- Construction stapler and staples 14-16 mm in size, level, tape measure.

Materials and tools for door insulation

Materials and tools for door insulation

Insulation works

Immediately before insulating the canvas and sealing the gaps, cracks, distortions, loosening, sagging, and other visible door defects should be eliminated. The cracks are covered with putty on wood, the gaps and skew of the canvas are regulated by canopies. On the wooden door you can seal the screw holes for the hinges so as not to re-hang them to a new place. An extreme measure to eliminate the loose closing of a wooden door or its distortion is the use of a planer.

The choice of a sealant for any door is a serious matter, since different materials will behave differently:

- Foam rubber seals are usually made with one self-adhesive surface, and they are not reliable and durable. Their advantage is cheapness;

- The rubber seal is a narrow tape with a sticky surface. The tape is sold without an adhesive surface, and then it can be glued with a regular rubber glue after cleaning the work surface. On a wooden door rubber compressor can be nailed with small nails;

- A felt seal in the form of a tape is nailed to the frame of a wooden door or glued to metal (plastic) with rubber glue. The thickness of the felt tape depends on the gap - if you need to make the tape thinner, it is cut with a carpentry cutter;

- The sealing tape and plastic or silicone is much more elastic than rubber or felt, it is poorly compressed under the pressure of the canvas, so it will last longer. Both silicone and plastic do not crack from frost, do not deform or stretch, they make hermetically sealed surfaces.

Felt door seal

Felt door seal

The tape is fastened and placed around the perimeter of the frame without gaps, the length of the tape may be more than necessary, but not less, so that you do not have to make an additional connection, which will reduce the tightness of the seam. The thickness of the tape is set with a piece of plasticine - it is glued to the frame, the door is closed, and after opening it, it will be seen how thick the seal is needed.

Replacing the seal on the front door

Replacing the seal on the front door

Any tape seal must be fixed if the thickness of the factory seal is already insufficient to prevent drafts, and combining decor with insulation is the most reliable measure.

Door insulation, self-adhesive, felt, upholstery

Insulation of entrance doors is relevant both for a private house and for an apartment in a multi-storey building, since heat loss through a doorway in the cold season can reach up to 20%. The easiest and cheapest way to eliminate drafts is to fix the door insulation in problem areas of the opening. The traditional material for creating a barrier to the penetration of cold air into housing is ordinary building felt, but besides it, there are a lot of modern synthetic insulation, and about the whole variety of these materials - below.

Felt insulation: application, installation

Felt comes in rolls and sheets.

In one of our earlier articles, we introduced you how to insulate a bathroom. Today we will talk about a very old, but, unfortunately, lost its popularity insulation made of natural sheep wool - felt. For the insulation of doors, window and door frames, the crowns of log houses, this material fits perfectly. But if you want to completely isolate the house with them, you will encounter many problems, the solutions of which are extremely difficult to find. “There are no hopeless situations,” the notorious Baron Munchausen used to say, but, despite this, there is still no developed clear method for insulating walls with felt.

What is felt insulation for doors

What a pity that this excellent, natural material with excellent characteristics is almost forgotten. Today, felt is used to insulate doors and window openings. AT ordinary houses and ends there, if we are talking about wooden structures or a bathhouse from a log house (beam), then it is also used as an interventional insulation and for caulking cracks. And, probably, no one even knows that felt insulation can be different:

- technical fine wool - manufactured in accordance with GOST No. 288-72;

- technical semi-coarse - made in accordance with GOST No. 6308-71;

- technical coarse wool - manufactured in accordance with GOST No. 6418-81;

- yurt - manufactured in accordance with GOST No. 16221-79;

- fert - made from the finest fibers of six rabbits and goats.

Felt insulation has a fairly low thermal conductivity, the coefficient is 0.03-0.07 W / m * K and depends on the density of the material. The latter varies in the range from 10 to 400 kg/m. cube

The material is produced both in panels and in rolls. The dimensions of the panels are 2000 x 2000 mm, rolls are up to 1800 mm wide and up to 200 m long. It is made from both natural raw materials and synthetic ones. Synthetics are already a trend of our time, you should not take it seriously, but natural materials deserve attention.

This is a seal for crowns, 15% consisting of felt.

In addition to the fact that felt is produced in its pure form, it can be part of other natural insulation materials. For example, felt jute, where impurities are up to 15% of total weight material. It is produced in tapes and is used for laying between the crowns of buildings made of logs or timber, as well as for sealing gaps between logs and in corners (bowls).

Felt insulation for doors was originally used to make felt boots. The very name of this shoe tells us about the method of its production. Felt boots are made from natural sheep wool by dry or wet felting. As a result, the villi are so interconnected that a monolithic carpet is obtained. Anyone who spent at least one winter in felt boots knows firsthand about their qualities. Accordingly, felt insulation for doors has all these characteristics:

- repels moisture, but still gets wet;

- when wet, does not lose heat-insulating qualities;

- excellent sound insulator;

- not harmful and non-toxic;

- does not burn in the natural environment - to maintain combustion, more oxygen is needed than is contained in atmospheric air;

- it does not contain harmful bacteria.

It would seem that the felt seal for the door is just an ideal material, but no, there is one drawback. He is very fond of eating moths, and if it has already started, then it is extremely difficult to remove it. In this regard, the material in production is treated with a 3% solution of sodium chloride.

The question of what kind of heating for the house is better has been raised more than once, and there is still no clear answer. Each of the methods has both advantages and disadvantages.

The question of what kind of heating for the house is better has been raised more than once, and there is still no clear answer. Each of the methods has both advantages and disadvantages.

How to insulate the door in the bath with felt

Most often, felt is used for insulating door and window frames, as well as for external door insulation. The fact that the material is environmentally friendly and that it breathes makes it possible to use it even in baths at high temperatures and humidity. Consider the insulation of the door in the bath with felt from two angles. The first will be the insulation of the box.

This technique is applicable both for entrance doors and for entering the steam room. In both cases, felt door insulation is laid along the perimeter of the box at the junction with the movable part. For this you need:

- roll the felt into a small roll;

- on the side where the edge is visible, the roll is laid around the perimeter of the box;

- fastened with nails or a stapler.

No additional protection is needed. If it is necessary to insulate the front door with felt, then you need to take a panel and fix it on the outside. Then, using furniture nails with beautiful caps, fix the material you like (usually a leather substitute) over the insulation. The main thing is that the finish is resistant to atmospheric aggressions.

The two-pipe heating scheme of a two-story house can be either vertical or horizontal. At the same time, there can also be several methods for wiring horizontal contours for each floor. Some of them: hitchhiking, dead-end, collector.

The two-pipe heating scheme of a two-story house can be either vertical or horizontal. At the same time, there can also be several methods for wiring horizontal contours for each floor. Some of them: hitchhiking, dead-end, collector.

Where else is felt insulation used?

Felt-based linoleum - insulation and soundproofing.

In addition to the above purposes, this material can be used for thermal insulation:

Methods, of course, are rarely used, but they are still discussed on the forums. Although felt for floor insulation is used very often as a substrate for linoleum. Considering the hypothetical possibility of laying insulation under finishing materials, for example, as foam wall insulation, you need to immediately cut off possible problems:

- moisture - although the material does not absorb moisture well, it still happens;

- moth - you need to impregnate the material with some kind of agent, but then you can forget about environmental friendliness;

- rodents - do not miss the chance to pull soft bedding into their hole.

As you can see, it is rather problematic to use felt for wall insulation, and the price bites. It is sold by weight and for a kilo they ask from 200 rubles, depending on the density. Such insulation will cost almost gold. As a local thermal insulation, a felt seal is suitable, but even the technology has not been developed for the insulation of large areas. How to be in such a situation when there is no one to even turn to for practical advice? On the forums on this issue, you will not find practitioners with fire during the day - some theorists are skeptical.

Warming the house with felt is a harsh reality

Despite all the positive aspects of this material, the complex insulation of the house with felt is not possible for a number of reasons:

- it absorbs moisture;

- moth starts in it;

- mice feel great in it;

- it is too expensive;

- there is no methodology for such work.

You can talk about how to insulate a door with felt from two sides:

- insulation of the box (joints);

- comprehensive insulation from the outside.

Also, this material is used for caulking interventional cracks. In addition, felt insulation for the walls of wooden houses is used as a gasket between logs (beams) during the installation of the structure. It can be used both in pure form and as part of other materials (jute). Attempts to completely insulate the walls of any buildings from any materials are best left. Yes, there is a strong felt for yurts, which has high insulating qualities, but it still won't work. It is not designed to be enclosed by a body of walls, because you are not going to insulate without finishing. Felt insulation for the floor is used quite widely, but only as a substrate for linoleum. It does not apply to laminate.

Felt sealant for insulation of doors, walls, floors of the bath

Felt sealant is available in rolls and sheets. They can insulate doors, walls and floors. Comprehensive insulation of the house with felt is impossible, there is no methodology.

A bath is a room that serves not only for hygiene, but also for strengthening human health, cleansing the body of toxins, and strengthening immunity. The bath involves the creation in its internal space of an atmosphere with high temperature and humidity, like a thermos. Naturally, any loss of heat and steam is unacceptable here, otherwise positive effect from bathing procedures can not be achieved. Therefore, for the owners and builders of baths, the first task is to insulate the walls of the bath from the inside, which contributes to the fullest use of the benefits of this wonderful type of recreation and recovery.

During the construction of a bath, first of all, there is a question about the environmental friendliness of all materials used - from supporting structures to decoration and interior equipment. Many try to initially use only natural materials in the construction. So, log cabin baths are, of course, the most popular today, although the most expensive. But often the owners prefer to build baths from cinder blocks, trying to use natural materials to a greater extent when processing the inner surface of the walls.

natural materials

Most often, for the thermal insulation of the bath, the owners use such natural materials as construction moss, felt, flax tow or hemp hemp. All these tools are excellent for fumigation of cracks in log cabins, as well as in baths made of other materials. These are environmentally friendly heaters, used for both internal and external thermal insulation.

Building moss based on plant components, such as cuckoo flax or sphagnum, is considered especially valuable because of its bactericidal properties. During the operation of the bath, moss gives a pleasant aroma, contributing to the most complete relaxation during the procedure. However, as a heater, moss has several disadvantages:

- Moss, like other natural materials, is easily damaged by insects, rodents and birds;

- It dries quickly, especially if the bath is not used for a long time;

- Moss is prone to decay, the formation of mold and fungal plaque, and this contributes to the destruction of the entire structure of the bath;

- thermal insulation process natural materials quite labor intensive.

Some owners may recommend the impregnation of vegetable insulation with chemicals, but this leads to the loss of all the valuable qualities of the natural material. Chemical impregnations themselves, when used in a hot and humid atmosphere, can harm human health with their fumes. To date, universal materials that contribute to best insulation bath walls from the inside, jute and linen fibers are considered.

Benefits of jute and linen

The thermal insulation of the bath from the inside can be done with jute felt, flax or flax-jute fibrous material. The advantages of all these insulating means are:

- Excellent thermal insulation qualities due to the low thermal conductivity of materials;

- Ease of laying and caulking;

- Resistant to rot, mold, fungus, insect, bird and rodent damage;

- Environmental friendliness - materials, although they have a factory-made type, but basically contain exclusively natural components of plant and animal origin without any chemical impurities;

- High resistance to temperature and humidity changes, as well as to drying out;

- Strength and durability.

Most often, mixtures of jute and linen fibers are used to insulate the walls of a bath structure, which can be purchased in the form of rolls of fibrous material of various thicknesses and widths.

Warming with other materials

In addition to flax and jute, when insulating a bath, ordinary heat insulators are often used, such as expanded polystyrene, polyurethane foam, mineral wool and dry bulk insulation - expanded clay, brick chips mixed with sawdust, etc. In addition, for the thermal insulation of the walls of the bath, fibreboard and chipboard are actively used.

Particular attention should be paid to the vapor barrier of the walls of the bath. The materials for the vapor barrier layer complement the overall heat-saving function of the walls, but at the same time protect them from rotting and mold formation, since high humidity inside the room can quickly destroy not only the insulation itself, but the entire building.

Vapor barriers

As a vapor barrier for a bath, you need tools that can withstand temperature extremes. Such materials include polyethylene film, glassine, aluminum foil and others. The vapor barrier layer must, first of all, be environmentally friendly, since in a warm and humid environment it will inevitably undergo evaporation, and then harmful substances can penetrate from its surface into the air of a bath or steam room if the owner has made the wrong choice.

by the most best material aluminum foil is considered for moisture insulation. It withstands high temperatures up to 150 degrees, is absolutely harmless, resistant to decay, mold and is very durable. Often, heat-insulating materials are used to insulate the walls of the bath, which already have a layer of aluminum foil on one of the surfaces intended for the interior space. For example, prefabricated styrofoam or fiberboard often has a foil surface on one side.

In addition, seams and joints between insulation should also be sealed using foil tape, which often has a double-sided adhesive surface. Thus, the walls of the bath are covered from the inside with a continuous layer of heat and moisture insulation, which helps to create the appropriate atmosphere for wellness procedures to the maximum extent.

In addition to the foil vapor barrier, kraft paper is also successfully used. It is good to use for a steam room, as it creates an excellent sealing of the room and at the same time insulates it in addition to other heat-insulating means.

Usually, a special frame made of wood material, the so-called crate, is superimposed on top of the insulation inside the bath. It is necessary for further finishing the walls of the bath, because it is to the crate that finishing finishing products are fixed - panels, plates, interior fittings, shelves and others.

Ventilation gaps

When insulating the walls of a bath building, many owners create a system of ventilation gaps - special spaces located between the insulating material and outer wall. These are very narrow slots necessary to remove excess steam and air from interior. Moreover, such ventilation does not affect the microclimate of the bath from the inside, since excessive moisture goes into the ventilation gaps very slowly, gradually, through microscopic pores in the heat-insulating layer of the walls.

Even at minimum speed and invisibility to the internal atmosphere of the bath, ventilation largely protects the entire building from premature destruction due to increased dampness, rotting and mold formation. Narrow air gaps can be left in the thickness of the walls, foundation and ceiling, and can be equipped with special outlet pipes.

Thus, using all these nuances - the right choice of insulating materials, the use of suitable vapor barriers, the creation of a multilayer insulation structure, leaving ventilation spaces - you can create an excellent source for rest, recovery and relaxation - a Russian bath.