Technologies for the construction of private houses. New technologies for building a house Modern building

One of the criteria that individual developers are guided by when choosing a particular project is the speed of construction of the building. There are many explanations for this - the desire to quickly move into own house; surprises presented by the weather, which often complicates technological operations and delays the completion of the facility.

And the practical side of the issue is also an important factor. In most cases, you have to rent something (a concrete mixer, for example), the fee for which is mainly calculated by the day. New technologies for the construction of cottages and private houses, depending on the qualifications of the craftsmen and the thoughtfulness of the preparatory measures, make it possible to build model house Literally 2-3 months. That's about them and will be discussed in the proposed article.

The author draws attention to the fact that technologies and new building materials should not be confused. For example, foam concrete, OSV slabs, and so on. This is already different, although the application and installation of each of the samples has its own specifics.

The latest building technologies

TISE

It also has other names in everyday life - “folk”, “adjustable formwork”. Unlike many technologies, including the latest ones, this is a purely Russian invention. One of the advantages is the ability to literally do everything on your own, which is especially appreciated when building private houses.

Peculiarities

- With this technology, columnar or pile foundations are erected. As an option - varieties with a grillage. The main working tool for this stage serves as a drill specially designed for TISE.

- The walls are built from blocks, and hollow ones, which are formed right at the place of their installation. For this, formwork modules are used; they just need to be changed from time to time. Therefore, having fixed them on any segment where the wall should be erected, it remains only to load the solution and wait for it to seize. After that, the modules are dismantled and reinstalled on a new site.

Advantages

- The absence of so-called "cold bridges". By the way, one of the main problems that most private developers have to solve to reduce heat loss.

- Minimum number of employees. When erected using this technology, they will need 2 - 3 people (the owner himself and a couple of assistants at most). And then, only for individual operations. Basically, for reinstallation of panel modules, soil drilling.

- You do not have to rent or attract any equipment, which gives tangible savings.

- The possibility of combining various building materials in such walls. As a rule, concrete + brick.

Frame technology

So far, it is not practiced so often in our country, but this is rather due to the poor awareness of individual developers.

Peculiarities

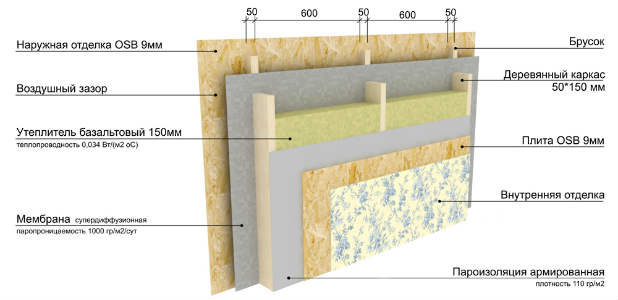

After the foundation is erected, the frame is assembled. In fact, this is a structure that combines vertically, horizontally and diagonally oriented beam elements. Basically, these are metal or wooden blanks - to whom and with what it is more convenient to work. Metal samples are stronger, but fixing something on them, articulation with each other is possible only after drilling holes, or using a welding machine.

Based on this, during the construction of private houses, preference is given to wood during the installation of the "skeleton". Basically, this is a beam, since its correct geometry greatly facilitates the assembly of the structure.

Walls are nothing more than sheathing. During their construction, they can be used as various materials as well as technology. They are available in two versions. The first is walls with filling, when almost any heat-insulating materials are laid (filled up, poured) between the cladding elements (for example,). It can be foam concrete, mineral wool, expanded clay, polyurethane foam or something else. The second is prefabricated panels, in which both waterproofing and insulation are already laid.

Although the latter option for making your own hands is less appropriate. It is difficult to accurately assemble the shields in compliance with all the features of the technology. Yes, and manual installation of such massive modules in place is impossible - you need a crane.

Advantages

- With this method of construction, you can equip the foundation of any type. This technology is recommended on all soils, including the "problem" category.

- Possibility (if desired or necessary) of quick redevelopment with minimal cost. The same applies to increasing the size of a private house. Making an extension to it, expanding the dimensions of the premises is not a problem. It is enough just to install additional racks of the frame and make the sheathing of new walls.

- The "finishing" decoration of a private house is made with any materials. There are no restrictions in this plan, which allows the owners to choose the most economical option.

3D panels

This technology is somewhat reminiscent, although there are differences. The panels, although industrially manufactured, are not prefabricated panels, but monolithic slabs of expanded polystyrene, which are reinforced on both sides with reinforcing meshes. Their mutual fixation is carried out by metal rods penetrating the polymer diagonally. On the one hand, the assembly is strong, on the other hand, it is characterized by low weight.

Peculiarities

- As such, the "skeleton" of a private house is missing. Its role is played by the panels themselves, which are rigidly fastened together, forming the walls of the building.

- After the installation of the entire structure, it is covered with a concrete "shirt". Accordingly, the shell is arranged on both sides of the 3D panels.

Advantage

Given that the walls are basically polymer, such private houses are characterized by minimal heat loss.

In the construction of buildings, SIP panels are also used - this is also from the field of the latest technologies. But in the construction of private houses, they are practically not used. The main reason is the large dimensions of the products. Their main purpose is the construction of large-scale facilities (administrative, industrial and other buildings).

Therefore, it is hardly appropriate to pay attention to this technology if the topic of the article is private houses. As an option, order SIP panels according to your own drawings. But who will be interested in this if such construction comes out "for a pretty penny"?

Fixed formwork

This technology has increasingly become practiced in the construction of private houses, since it is basically better known.

Peculiarity

The formation is made from various samples (block, panel) that are installed along the perimeter of the foundation, with a distance (along the width of the tape) from each other. In the resulting cavity, after installing the reinforcement elements (rods), a concrete solution is poured.

Advantages

- Almost the entire cycle of work can be done alone. If assistants are needed, then perhaps at certain stages of the construction of the foundation and floors.

- Such private house, at right choice wall formwork material, does not need additional insulation.

The latest finishing technologies

They should also be listed, as they are directly related to the construction industry. For more information on each technology, follow the link.

- "Wet" facade.

New materials

- Penetrating waterproofing.

- Reinforcement - strained and.

- Decorative plaster.

This article gives general information and is, in fact, an overview of all the latest technologies. For example, it is quite interesting to build using the EcoCube method, which uses panels assembled on the basis of high-density straw bales covered with a metal frame. The thermodom technology is gaining popularity.

The author considered it appropriate to consider the features of only those construction technologies that are better known in our country and are in demand among private developers. In addition, it is quite difficult to classify all the technologies in practice. This is due to the fact that many of them are mixed, since their individual elements are to some extent similar or completely repeated - according to the method of installation of structural parts, the materials used at a particular stage of work.

But the information presented is enough to decide from what it is still better to build a house. And all the other nuances can be clarified either independently, or consult a specialist.

Development of building technologies, development and application of new building materials conducted in the following directions:

- reducing construction time and increasing the profitability of construction,

- reducing material consumption and costs during construction, operation and repair,

- increase durability building structures and, in general, buildings (buildings and structures),

- improvements and diversity architectural forms, space-planning and functional solutions, improving the physical parameters of existing and constructed facilities.

- To fulfill these tasks, all economic entities associated with construction (scientific institutions and design institutes, laboratories, enterprises for the production of building materials and construction organizations) are looking for solutions in terms of the development, production and use of new building materials, structures and technologies. Ultimately, this leads to improvement. specifications real estate objects, reduces operating costs during their use, increases economic efficiency during the entire period of the objects' service life.

Innovation in the development of building materials and structures follows the path:

- increase strength and durability,

- increase resistance to aggressive environments,

- increase moisture resistance, water resistance and water tightness,

- increase frost resistance,

- increase resistance to corrosion of metals,

- decrease in thermal conductivity,

- widespread use of local and most common minerals in the construction industry.

New materials and designs are used in the construction of all constituent parts buildings, structures and structures:

- foundations (for example, precast concrete, monolithic reinforced concrete, pile, columnar and strip foundations, foundation slabs, etc.),

- building frames (from monolithic and prefabricated reinforced concrete, from metal-roll, using new fastening technologies),

- enclosing structures (walls and partitions),

- structures of interfloor floors and coatings (roof, roofing),

- a wide range of finishing materials,

- engineering systems, equipment and communications.

Examples include:

1. Heat efficient blocks . They are made of two layers of solid, load-bearing material with a layer of insulation between them. The solid layers of the block are interconnected by rods. The front part of such a block is decorated with texture, color, ornament. The size of the front part of such blocks is usually 400x200 and the thickness (wall width), depending on the climatic conditions of the area, is 250 - 400 mm. As a result: a wall made of such blocks has a high thermal protection, the construction time of the building is reduced, and a high qualification of a bricklayer is not required when performing masonry.

2. gas silicate blocks. Their standard sizes are: 600x300x200, 600x300x100. The blocks are manufactured in a factory and have a porous structure. They are molded from a mixture of quartz sand and lime. At a high temperature in an autoclave, voids - pores are formed in the structure of the gas silicate stone, which further, during the operation of such a material, provides excellent thermal insulation properties along with their high strength. Gas silicate blocks are used for the construction of external and internal load-bearing walls and partitions. To provide the necessary thermal protection of the building, the outer walls are insulated with a layer thermal insulation material, protective and finishing layer.

3.

Sandwich panels and prefabricated buildings.

Sandwich panels are large-sized three-layer structures for side railings and roofing of buildings. Panels are manufactured in unified dimensions under industrial conditions from metal, usually galvanized profiled sheets, painted with polymer paint of any desired color, with a heat-insulating layer between them made of a highly effective heat-insulating material, for example, expanded polystyrene, polyurethane foam or mineral wool. Under construction conditions, sandwich panels are mounted on a metal frame made of unified, factory-made parts. The frame consists of steel columns rigidly fixed in columnar reinforced concrete foundations, and metal roof trusses hinged on them. To ensure the rigidity of the entire building, protection from wind and snow loads, the frame is erected using vertical and horizontal ties. All elements of such a building are manufactured in the factory, which allows you to achieve best quality materials and structures, the highest labor productivity and high profitability in the production of all elements of the building.

The use of such technology construction industry allows you to significantly reduce the construction time of buildings with high quality work. This has become a real "breakthrough" in the construction of modern trade and exhibition complexes, industrial, warehouse and office buildings, sports and fitness complexes and facilities, aircraft hangars, car dealerships, car services and garages, that is, the entire spectrum of commercial real estate. The construction of prefabricated buildings gives the investor the opportunity to put construction objects into operation as quickly as possible and recoup the investment. In a market niche, this provides additional competitive advantages. The durability of a prefabricated building is determined by the durability of metal structures and depends primarily on the degree of probability of corrosion of metal parts. To protect against corrosion, new technologies for the production and processing of metal structures are being applied and developed. With the high quality of component parts, high quality of production and control during the construction period, as well as subject to compliance with the rules of operation and timely current repairs Most manufacturers declare the operational service life of prefabricated buildings to be at least 50 years, and some name a period of up to 100 years.

4. Dry mixes - these are mixtures almost ready for construction and repair, obtained under industrial conditions by mixing dry components in proportions strictly dosed to ensure the required properties. The following are used as components: cement, sand, gypsum, lime or other mineral fillers with the inclusion of special additives. Under construction conditions, to prepare the solution, it is necessary to mix the right amount of the mixture with water in a certain proportion and mix thoroughly. This reduces the time of work, significantly improves the quality of building structures and elements, increases the durability of the building as a whole.

5. Penetrating waterproofing. Many buildings and their elements require reliable waterproofing during construction and repair. Waterproofing protection is needed for the foundation, roofing, walls made of porous materials, as well as other elements that are in an aggressive environment. Many waterproofing materials used in the past often could not provide reliable protection due to poor quality work. Rolled waterproofing materials themselves are waterproof, strong and durable. However, in the conditions of construction (or repair), the mistakes of the contractor and violations of the technology of waterproofing work, especially in hard-to-reach places, lead to depressurization of the insulation. Then the low-quality waterproofing layer is covered with subsequent layers of materials (screed, tiles, etc.). As a result, if leaks are detected during the operation of the building, it is most often impossible to identify the place where the waterproofing is broken. It is necessary to apply new layers of waterproofing, which again does not provide complete reliability for the reasons indicated above (poor-quality work, technology violations, hard-to-reach places). To solve this problem, penetrating waterproofing was created. This material is produced by the industry in the form of a dry construction mixture of cement and high-aluminate clinker, polymer binders, fillers and polymer additives. For use in construction or repair conditions, the dry mixture is thoroughly mixed with water. When the resulting solution is applied to a solid, wet and porous stone surface, the chemical constituents under the influence of osmotic pressure penetrate deeply into the capillary structure of the surface. As a result of the interaction of chemical components with the mineral surface, insoluble and sparingly soluble salts are formed, which block all pores, providing water resistance, strength and resistance to aggressive waters. Depending on the density of the surface, the depth of penetration into the internal structure can be up to 10 centimeters.

6. New window technologies already known to a wide range of consumers. modern windows made in industrial conditions from polyvinyl chloride (PVC) or aluminum profile with sealed one-, two- or three-chamber double-glazed windows. Double-glazed windows are several layers of high-quality glass with a thin layer between them, filled with dry air or an inert gas. All connections of window blocks are made of such high quality that they provide complete protection against the penetration of moisture and cold air.

7.

Monolithic construction

.

The use of modern reliable and multifunctional construction machines and equipment, equipment (concrete pumps, concrete trucks (mixers), concrete plants, inventory formwork) and modern plastic concrete allowed the construction industry to move to a new technological level - the construction of monolithic reinforced concrete buildings. reinforced concrete frame, interfloor ceilings and coatings modern building literally "poured" from concrete into a form, which is reinforced in advance and fenced with inventory formwork. This provides significant advantages compared to previously used technologies:

Walls and ceilings built according to monolithic technology, uniformly reinforced, practically have no seams in concrete, which ensures the design strength and rigidity of the building, protection of the reinforcing metal frame elements from corrosion and aggressive environments.

The load-bearing elements of the structures have a smaller thickness, which reduces the load on the foundation and the underlying structures. As a result, this reduces the overall construction costs.

It became possible to design and build buildings, unique in their architecture and layout, of any shape and configuration.

The load-bearing frame made of monolithic reinforced concrete has significantly better strength characteristics, which makes it possible to erect high-rise buildings 30 - 40 or more floors.

Compared to prefabricated reinforced concrete construction, the need for sealing joints and seams of reinforced concrete elements during the construction period and their regular repair during the operation of the building is excluded.

8. Ventilated facades. 90% of the buildings that exist today, built 30-50 or more years ago, came into an unsightly appearance, the facades were either not faced at all during construction, or the plaster cracked and collapsed, and the facade paint deteriorated. In such conditions, the walls of most buildings are not protected from rain and wind, and in our climatic conditions, in conditions of significant temperature fluctuations (heating up to +40 - +50°С and frosts down to -30 - -35°С), there is a rapid destruction of surfaces enclosing walls (brick, concrete) from narrowing and expandingstructure of the stone during drying, waterlogging, freezing and thawing. As a result, non-old stone buildings built on good foundations, with good strong frames, with strong bearing walls and ceilings, which could serve for more than one hundred years, come into disrepair after 50 - 70 years due to the insecurity of the enclosing walls.

Not so long ago in Russia (and it has been used in the world for about 50 years), a new technology for protecting the walls of buildings appeared - "ventilated facades". This technology is a hinged cladding system consisting of brackets, profiled guides, fasteners and other elements and can be applied at any time during the existence of the building (the sooner the better): during the construction period, during the reconstruction period, during the repair period.

The most important advantages of using ventilated facade technology are:

protection of external structures of buildings from external influences (humidity and temperature changes),

giving buildings a beautiful and "well-groomed" appearance,

creation of new architectural lines of buildings and color solutions: various options and colors of finishes (porcelain stoneware, composite, metal or other panels),

insulation of buildings and improvement of their thermal performance,

ease of assembly of factory-prepared elements.

Ventilated facades are an excellent modern technology for protecting buildings from external influences, giving the most modern look even outwardly very obsolete buildings and a significant extension of the life of each building!

In addition, in conditions of the necessary energy savings, ventilated facades provide an additional air gap or provide a layer of insulation, increasing the thermal performance of buildings. As a result, the payback period for a ventilated facade is 5-6 years, and the period of maintenance-free service is 30-40 years. And most importantly, the cost of such a facade is disproportionately less than the cost of new construction to replace the emergency building!

Thus, along with the advantages of technical and aesthetic "orders", ventilated facades will bring undoubted benefits to building owners:

increase the durability of buildings and preserve the value of the investment capital of the owners for many years,

increase the performance of the building by saving the cost of heating and repairs of enclosing structures,

will give each such building a magnificent "presentation", increasing the attractiveness for potential tenants and potential buyers,

and, ultimately, will significantly increase the capitalization and market value of such buildings.

A couple of decades ago, private housing was built using a single technology. But the construction industry does not stand still, and today, thanks to modern materials and new technologies in the construction of private houses, the developer receives many benefits: the construction time of the facility is accelerated, installation is simplified, the economic efficiency of the project increases, and the operational life of the facility increases.

Modern technologies in construction

Assume high-tech building materials, new methods of their installation, non-standard technologies of the entire construction process. As a result, a private house has higher performance characteristics. Let's take a look at some advanced technologies.

Chise

Technology of Individual Construction and Ecology (Tise) was invented by Russian builders. Its other names are “folk”, “transitional formwork”. The main advantage of Chise is the ability to build a house on your own, without the help of specialists.

The method of building houses according to Chise is as follows:

- The foundation is built from piles or pillars, united by a reinforced concrete frame (grillage). For drilling wells, a drill of a special modification is used.

- The walls are assembled from hollow concrete blocks. They are made directly during the construction of masonry using portable formwork.

- To connect the blocks, special protrusions are provided, so there are no masonry seams, and hence the cold bridges that form in them.

- All work, with the exception of drilling and formwork transfer (this will require 1-2 assistants), is carried out by one person.

When using Chise technology, there is no need to hire special equipment, and the filler for the walls is chosen independently.

frame construction

For now frame construction individual housing is not used often, but it has good prospects for the future. A house using a new technology is being built on the basis of a frame of beams arranged vertically, horizontally and diagonally. You can use metal blanks, but their installation complicates the construction process. Then the crate is sheathed. The space between the sheathing and the beams is filled with a material with high thermal insulation properties: polyurethane foam, expanded clay, foam concrete or fibrous insulation.

by the most good option for sheathing are OSB boards. There is another option - prefabricated panels, which are already equipped with waterproofing and insulation. But it is more expensive and more difficult to perform, requires special equipment and engineering knowledge. You can use sandwich panels, which, compared with brick building 10 times more economical.

The advantages of frame-panel houses include the fact that any foundation and any type of soil is suitable for them, and by installing additional frames, you can easily redevelop or complete the premises.

The 3d-panel method combines frame-panel and monolithic construction. The know-how of this technology lies in the fact that instead of prefabricated panels, polystyrene foam plates are used, reinforced on both sides with a reinforced mesh. They form the frame of the building. The plates are connected using metal rods, which are welded to the grid diagonally. As a result, a spatial 3d construction is formed, which gave the name to the method. After installation, the panels are covered with a concrete "shirt" outside and inside.

Although the idea of this technology originated in America, it is known in Russia and neighboring countries under the Russian Wall brand. The advantages of 3d-panel construction include the fact that the polymer materials used for the manufacture of plates are a reliable insulation, which helps to keep the heat in the room. In addition, installation is simplified due to the low weight of monolithic EPS boards.

Among the new technologies in the construction of houses, fixed formwork is often used. It consists in the following: formwork is constructed from panels or blocks, reinforcement is inserted into the cavity of which and a concrete mass is poured that performs load-bearing functions. The slabs that form the wall configuration are not removed and are used for insulation.

The advantages of this technology (sometimes called "Thermod" or "Izod") include the need for a minimum number of builders, and with the right choice of formwork filler, you will not have to do additional thermal insulation.

The novelties of prefabricated houses include modules - ready-made building elements that are manufactured at a construction plant. Engineering communications are laid in them, windows and doors are inserted. It remains for the developer to install the modules on a pre-constructed foundation and connect them with special fasteners.

Foreign experience

Individual buildings are popular all over the world, therefore, interesting experience of such construction has been accumulated in Europe and America. It is dominated by technologies aimed at the rapid construction of economical housing. Much attention is paid to the comfort and environmental friendliness of the building materials used.

In Canada and Finland, wood-frame construction is predominantly used. In the US, 95% of low-rise buildings are built on wooden base. Japanese builders are more likely to use frame construction. They also developed an innovative technology for building an economical and durable dome-shaped house, for which ready-made foam modules are used. Such a structure does not require a foundation and is assembled in 1 day.

In Germany, more than half of private housing is built from porous concrete, a large segment is made up of stone and brick buildings. This is due to the shortage of cheap wood building materials. However, the country is the largest exporter wooden houses. The walls are finished with brick or plaster, followed by painting.

The house needs to be heated, so the development of projects for new types of heating with options for heating a private house does not stand still. As an alternative to centralized or stove heating, it is proposed to use solar panels, infrared emitters and heat pumps that extract heat from the earth, air or natural water. More and more popular electrical systems"Warm floor" and " Warm panel».

Modern heating systems are equipped with "smart" automation, which allows you to save heat energy and even control heating remotely using a smartphone.

Construction - one of the key industries in the XXI century. In modern construction, new developments are underway to create new building materials and construction technologies in order to improve the quality of buildings and structures, their durability, construction speed, as well as reduce the economic costs of materials and work. This article will present new innovative and information technologies in construction.

Innovative technologies - these are the means and methods intended for the consistent implementation of innovation. With their help, you can improve the basic properties of buildings, as well as the speed of their construction. Technology does not stand still, and scientists have already been able to implement several ideas.

- "Flying" houses

Japan never ceases to amaze with its developments. The idea is simple - so that the house does not collapse as a result of an earthquake, it simply should not be on the ground. So they came up with flying houses, and all this is quite real. Japanese construction company Air Danshin Systems Inc has developed a system that allows buildings to rise above the ground and "float" above it during an earthquake. The house is located on an air cushion and after the sensors are triggered, it will simply hover above the ground, and during such a change, the residents of the building will not feel anything.

The foundation is not attached to the structure itself. After soaring, the house sits on a frame located on top of the foundation. During an earthquake, sensors are activated, which are located around the perimeter of the building. After that, they will immediately start the pressure compressor located at the base of the house. It will ensure the "levitation" of the building at a height of 3-4 cm from the ground. Thus, the house will not be in contact with the ground and will avoid the consequences of tremors. "Flying houses" have been developed by many Japanese firms, in the near future know-how will appear in other regions of Asia, which often suffer from earthquakes.

2. Technology for building domed houses without nails

Scientists of the Far Eastern Federal University create modern wooden domed houses, while, as in the good old

times of Russian architects, - without single nail. Their uniqueness lies in the use of new designs of locks between the individual parts of a wooden spherical frame. Dome house from wooden parts created in record time. Literally in a matter of hours, the frame grows unusual house. Today, they want to test this technology in several cities of Russia. Between themselves, the links are joined with the help of a special lock, which perceives all loads - vertical, lateral, and so on. Details are made with such precision that a kind of designer is obtained. Any person, having such a kit with a small assembly instruction, can mount this structure on their own.

- Self-healing elastic concrete

The idea of a similar material was found in ordinary shells. The fact is that the shells are enriched with the necessary complex of minerals that give them elasticity. It is these minerals that are added to the composition of concrete. The new type of concrete is incredibly elastic, more resistant to cracks, and even 40-50% lighter. Such concrete will not break even with very strong bends. Even earthquakes are not afraid of him. An extensive network of cracks after such tests will not affect its strength. After the load is removed, the concrete will begin the recovery process. How does this happen? The secret is very simple. Plain rainwater when reacting with concrete and carbon dioxide in the atmosphere, it promotes the formation of calcium carbonate in concrete. This substance also fastens the cracks that have appeared, “heals” the concrete. After removing the load, the restored section of the slab will have the same strength as before. Such concrete is going to be used in the construction of critical structures, such as bridges.

For the successful organization of construction in a time of increasing competition, it is necessary to automate design and calculation work as much as possible, thereby saving time and human labor costs. Automation can be achieved using information technologies.

The use of information technologies in construction began with the solution of calculation problems. At present it is the most complex systems management of complex projects: architectural and construction design, calculations of load-bearing structures, programs for construction management.

Architectural and construction design

Among the programs for architectural design, AutoCAD dominates, surrounded by numerous application programs in various design areas. Prices and level of service - for every taste and financial possibilities. Among designers, such architectural and construction design systems as Speedikon, ArfaCAD, AutoCAD Architectural Desktop are most widely used. All of these software products make it possible to automate the work of a designer to a large extent and reduce development time due to built-in tools.

Structural calculations

The integrated system of analysis and design of building structures SCAD Office attracts the attention of specialists only in the CIS. The 32-bit SCAD system under Windows 98/NT is designed for strength analysis of building structures and systems, for example, load-bearing structures of the entire building, under static and dynamic effects. The allowable number of elements exceeds 65,000. A single graphical environment for the synthesis of the design scheme and analysis of the results provides unlimited possibilities for modeling design schemes of complex structures, meeting the needs of experienced professionals.

Construction management software

The construction organization management technology is so specific and complex that it can hardly be satisfactorily automated using modern versions of expensive systems such as SAP R / 3. Here, as a rule, special control systems are used. From domestic developments we can mention the systems "Bastion" (JSC "Petrostroysistema"), "Stroika" (IKF "Expert") and "Hector-Builder" (STC "Hector")

The software complex "Bastion" is an integrated system for conducting financial and economic activities of enterprises in the construction complex. The system allows you to track all the financial flows of the enterprise in the context of construction projects, departments, cost items, inventory control, control over the consumption of materials.

The complex of programs "Stroika" is mainly a corporate system. The Stroyka system was designed to automate management processes in large construction associations under a centralized management model, which was reflected in the architecture and basic principles of building the system. However, the team of developers, to the best of their ability, tried to keep track of the changes taking place in the country, as a result of which a multifunctional modular control system appeared, probably one of the most powerful domestic developments in this area.

Software complex "Hector-builder" is a set of interconnected software modules designed to solve the main issues of preparation and production construction works, automation of planning, including calendar, accounting for the actual performance of work, accounting for mutual settlements, material and technical supply of construction projects, as well as the release of estimates.

In the construction of residential buildings and outbuildings, new technologies are increasingly being used today. For the construction of buildings, modern materials are used that have excellent performance, reliable, environmentally friendly and durable.

What are the latest technologies in construction can be used

Innovative in our time include methods of building houses from:

- glued beam;

- foam concrete blocks;

- aerated concrete blocks;

- SIP panels.

Even when using conventional construction technologies, modern methods of finishing, hydro- and thermal insulation, pouring of enclosing structures, etc. can be applied.

Properties of glued laminated timber

This new material most often used for the construction of houses and baths. New modern technologies construction is not always cheap. Glued laminated timber belongs to the materials to some extent elite. Since it is quite expensive, household structures are rarely erected from it. The main advantage of this new material is strength and precisely calibrated geometric shapes. Due to the special configuration of glued beams, it is very easy to assemble houses from it. In addition, unlike profiled, such material does not shrink. The buildings erected from it look very modern and neat.

However, glued bursa has one small drawback. The fact is that glue is used in the process of its manufacture. As a result, such an important indicator as environmental cleanliness is deteriorating.

New technologies in the construction of houses, involving the use of glued beams, are not particularly difficult. However, when choosing this material itself, experts advise to pay attention to the manufacturer. It is worth buying such a bar only from trusted companies. Material purchased from an unknown company may be of poor quality. In this case, the walls assembled even in compliance with all recommendations can subsequently shrink, crack, start to rot, etc.

Advantages and disadvantages of foam concrete blocks

The latest technologies in construction involve the use of not only natural materials processed in a special way, but also artificially made. For example, country houses very often today they are built from foam blocks. Such buildings are simply remarkable performance characteristics. The advantages of foam blocks include:

- the ability to "breathe";

- excellent heat-preserving qualities;

- light weight;

- ease of use.

Lay the foam blocks on the glue. Moreover, it is applied, in contrast to cement mortar, very thin layer. As a result, cold bridges do not form in the walls.

But, of course, this material has its drawbacks. These include fragility in the first place. When erecting walls of foam concrete, it is imperative to use reinforcement. In addition, foam blocks are afraid of moisture. That is, for example, it is not worth building a bathhouse from them. Even residential buildings built from this material must be additionally sheathed with finishing material or finished with special plaster.

New technologies for the construction of private houses: aerated concrete blocks

This is another material that has gained immense popularity among the owners of suburban areas. Like foam concrete, it is a special man-made stone with a large number of small voids inside. Due to this structure, blocks of this type retain heat very well and are lightweight. The advantages of aerated concrete, among other things, include the ideal geometry of forms. It is very easy to trim walls from this material, because they have a perfectly flat surface. You can build a house from aerated concrete blocks very quickly. However, such walls also require reinforcement.

Characteristics of SIP panels

New technologies in construction, which have come to us from other countries, often allow us to build inexpensive buildings with excellent performance characteristics. In cottage residential and summer cottages today, quite often you can see light houses from SIP panels. The technology of building buildings from this material is called Canadian. The fact is that it was invented in this cold country. The main advantage of SIP panels is that they can be used to build very warm houses. The advantages of this material also include:

- Ease of installation. You can assemble a Canadian house in just a couple of weeks. In this case, it is not necessary to hire a construction team. The technology of building houses from SIP panels is very simple. They are attached to the beam with self-tapping screws.

- Ease of finishing. The walls of houses made of SIP panels are perfectly even.

- Possibility of quick redevelopment. Putting new or removing old partitions in such a house will not be difficult.

- High degree of sound insulation. From the side of the street, no sounds penetrate into such houses.

The latest technologies in construction, of course, can have not only pluses, but also minuses. The main disadvantage of SIP panels is that they do not let air through at all. As a heater in their manufacture, expanded polystyrene is used, which is also considered not too environmentally friendly material. In addition, such plates burn well.

Today on sale you can also find SIP panels with mineral wool. The risk of fire when using such material is significantly reduced. However, mineral wool also has a rather significant drawback - it is afraid of moisture.

What new technologies are still being used?

Among other things, in our time, such Newest technologies in construction as:

- penetrating waterproofing of foundations, walls and other concrete structures:

- pouring walls using mortar and fixed formwork;

- assembly of LTSC frames.

What is penetrating waterproofing

In Europe, this technology for protecting building structures from moisture has been used for quite some time. It was first used in Denmark. It is a penetrating waterproofing, a special composition intended for the treatment of foundations, walls and other structures erected using cement mortar. After applying to concrete surface it penetrates the pores and dries to form insoluble crystals. Thus, the absorption of water by concrete during the operation of structures is excluded.

Fixed formwork

New technologies in the construction of private houses often make it possible to build very inexpensive, light and at the same time warm walls. The main advantage of the technique of pouring enclosing structures using fixed formwork is the speed of work. When using such plates, it is possible to build the walls of even a large house in just one and a half to two weeks. A fixed formwork is made of warm polystyrene foam. Ease of assembly is determined by the features of its design and low weight. The use of such sheets, among other things, allows you to build buildings of the most complex layout. The fact is that on sale today there are not only ordinary, but also non-standard blocks of this type.

Some disadvantage of the building construction technology using fixed formwork is the need to use absolutely homogeneous concrete. Also, during construction, the assembly of the reinforcing cage should be taken with the utmost responsibility.

What is thin-walled steel structures

When erecting various kinds of structures of a large area, new materials and technologies can also be used. In the construction of various kinds of hangars, warehouses and ancillary facilities, light metal profiles can be used. Of these, the frame of the structure is assembled. With the use of LTSC technology, attics, utility and residential buildings are erected. But more often hangars are assembled on a profile frame for various purposes, storage and auxiliary premises. The advantage of such a metal base is, above all, ease of assembly. If necessary, the structure can be easily dismantled and put in a new place.

The disadvantages of LTSC include, first of all, deformation with significant temperature fluctuations and the impossibility of achieving high energy efficiency. Steel structures, unlike wooden ones, can freeze in the winter.

The high cost and complexity of building buildings and structures using traditional methods is the main reason for the need to use new technologies in construction. The use of modern materials allows you to assemble reliable structures quickly and at minimal cost. That is why SIP panels, foamed concrete blocks, glued laminated timber, etc. are becoming more and more popular. In most cases, in our time, houses are built precisely with their use.