How to make a vacuum cleaner from a plastic bottle. That's the inventor! Homemade cyclone for a vacuum cleaner from a plastic bottle Do-it-yourself vacuum cleaner from a bottle

When using a conventional vacuum cleaner to collect sawdust, the bag fills up very quickly. For myself, I solved this problem - I assembled a cyclone or a separator for working with power tools. Assembled from available and cheap materials:- an empty bottle of 19 liters;

- a fitting for the sewerage on 40 mm. (with a 90 degree bend);

- coupling and clamp also 40 mm;

- polypropylene pipe and fittings 20 mm;

- an old hose from a vacuum cleaner;

- a plastic bag and an elastic band.

Cyclone assembly

Two 40 mm holes were drilled in the bottom and side of the bottle with a crown. One hole for the hose from the vacuum cleaner, and the other for the hose through which the chips will be sucked. From polypropylene pipe a stand was welded to keep the bottle from tipping over. This was the most time-consuming work in the assembly of my entire structure.There is a clamp on the rack to fix the hose. And on the neck of the bottle is put on

garbage bag and tied with a rubber band. After the end of work (cleaning), the bottle rises, and all the garbage falls into the bag.

Basically the cyclone was assembled to work with mini circular saw and a jigsaw, when using which there is a lot of sawdust, but it has proven itself well when collecting ordinary garbage, since there is no need to change the dust bag now: it is almost empty.

There are different situations in life. If you suddenly need to use a mini-vacuum cleaner, you can save on the purchase and make it yourself.

1. Outline the label along the top and bottom lines. Cut out the part of the bottle where the marking label was.

2. Take an old empty can or tin can, remove the bottom and top, then cut in the middle to make a rectangular sheet.

3. Measure and cut a circle from the tin sheet to fit the diameter of the bottle.

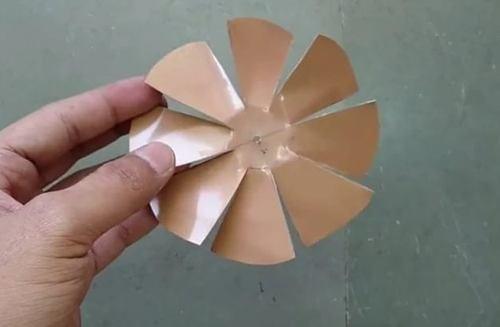

4. Leaving in the middle a place for a small motor, draw a tin circle and make cuts to make 8 sectors. Each of them needs to be slightly bent. Make a small hole in the center.

5. Now attach the motor to the resulting makeshift fan.

6. Using a drill and a large drill, make 3 rows of holes at the bottom of the bottle.

7. Glue the cap from another bottle to the motor, after passing the wires from the motor into the hole on the side.

8. Put the fan inside the bottle and glue it to the bottom. Glue the seal to the top of the bottle on the inside.

9. From the wire, make a ring with such a diameter that it fits in the bottle and can be placed tightly on top of the seal. Glue a circle of thin fabric onto the ring.

10. Put the ring in the bottle on the seal and close the structure tightly top bottles.

VK group http://vk.com/99diy

Hello! I am Andrey! And today I will show you a simple and most visual way of how to make a cool compact, really working, cyclonic vacuum cleaner with your own hands from improvised materials at home!

We will need:

Plastic bottle 2l,

- an empty metal bottle or sheet metal,

- 12 V 6000 rpm electric motor (can be found in an old hair dryer, car door lock activator, toys, etc.),

- plastic clamp

- fine mesh or mesh fabric,

- hot glue gun or any other glue,

- corrugated tube, for example, corrugation for electrical wiring,

- an empty tube, for example from glue,

- caps from plastic bottles,

- and etc.

This vacuum cleaner is perfect for cleaning in the workshop, on the desktop, in the car or in hard-to-reach places. Compact and portable provide wide spectrum terms of use. Such a vacuum cleaner can work both from the power supply unit and from the rechargeable battery.

99% Do it yourself

Attention! Be careful and do not repeat this at home, the author is not responsible for your actions, this is an entertainment video, not a training or a call to action!

Video How to make a vacuum cleaner from a bottle with your own hands? / How to make the vacuum cleaner out of the bottle? channel 99DIY

How to make a vacuum cleaner? A homemade unit assumes the presence of an engine at 6000 rpm. Such a part can be removed from the juicer. Please note that not all electrical appliance motors are designed for a long service life. Therefore, when choosing an engine, follow the rule: the motor must withstand a large load and have protection against overheating.

What to do if you can’t find anything other than a part from a juicer?

In this case, it is advised to equip it with a thermal fuse rated at 126 ºС. The cross section of copper must correspond to the dissipation power, so this temperature may not be suitable for the motor you have chosen. It should be noted that the border of 130 ºС is the average for which most transformers are designed.

What can be taken as the basis of a homemade unit?

Many are interested in how to make a vacuum cleaner with your own hands.

You can take as a basis:

- An exhaust motor with an Axial model will not work, as it is used in models of a cheap segment and does not have the necessary power.

- Disused vacuum cleaner engine.

- Engine washing machine.

- Refrigeration compressor motor.

Refrigerator engine application

How to make a vacuum cleaner from It will be difficult to pick up a part, since the rotation speed of the shaft is different models refrigerators are different. If you are assembling a vacuum cleaner, then a strict 6000 revolutions will be required. Compressors of the old rocker type are designed for 3000 rpm.

Crank modifications have half the speed, and linear inverter units are not at all suitable for assembly.

Inside the piston compressor is an electric motor. If you cut the case and remove the motor, then it is suitable for any purpose. It has high power and quiet operation.

Asynchronous motors are rarely used. For example, a collector configuration operates from the outlet if speed control is not required.

Using a washing machine motor

The design of washing machines assumes the presence of a collector motor. The speed of its operation is regulated by a thyristor key. If the motor is powered directly from the outlet, then the speed will become high, but they will not reach the figure of 6000 in the absence of a belt gearbox. In this case, the spin function is quite achievable.

How to make the unit suck dust?

Commercials often talk about the vacuum created in the vacuum cleaner. The engine allegedly contributes to the discharge, into which the drawn-in air stream rushes. But is it really so? Rather not, because at negative pressure, a bypass valve is connected to ensure balance. But that is not the essence of the work. To suck dust, a hermetically sealed housing is used, thanks to which the flow of nitrogen and oxygen molecules rushes in the right direction. The container in this case does not play any role.

If you stick to the factory configuration, then you need a bucket made of steel or plastic, the bottom of which has an air intake hole. The motor is mounted on the axis, and something similar to a squirrel cage is installed on the shaft. The air flow is captured by the blades and thrown out to the perimeter. This provides traction. A hose is hermetically attached to the bottom. We will assume that the assembly of the vacuum cleaner with our own hands is completed.

How does a mini vacuum cleaner work?

How to make a mini vacuum cleaner? The speed control of the unit is carried out according to the thyristor circuit. Any electronic part from an old vacuum cleaner, washing machine or food processor will come in handy.

The main thing is the cutting method, not the engine power. But the key also overheats. It is easy to understand whether it corresponds if you compare the power of the device from which the circuit was taken with the power of the engine. If the thyristor indicator is low, then it is advised to attach a radiator to it, and forced cooling is already available.

How to make a container for a homemade vacuum cleaner?

The vacuum cleaner is designed in such a way that it will not work without a container.

For a homemade unit fit:

- ordinary bag;

- a container filled with water;

- cyclone chamber.

Filtering the bag is problematic. If you will be vacuuming crumbs from the table, this design is fine. The type of container is selected according to the type of waste. For example, dust collection is best done through a filter with water or a cyclone chamber. Both types of container are easy to construct. The unit itself is stationary. If a gardener uses such a device, then it can be hoisted onto a cart and moved around the garden.

The cost of stationary models of vacuum cleaners is high, so homemade construction will be most welcome.

The simplest container model is a large tank filled with water. It plays the role of a water filter. In this case, the dust will sink. The inlet of the hose is made taking into account that the flow collides with a water barrier. An ordinary flat-bottomed box is two-thirds filled with water. In addition, a baffle hangs from the ceiling above the filter surface. All the dust settles in the water and sinks. Such a device requires periodic cleaning. Such a design will not be suitable for gardening, as the weight of the water is large. Therefore, it is replaced with air.

When assembling vacuum cleaners for the garden with your own hands, adhere to the following rules:

- Air enters tangentially into the tall barrel.

- Along the axis of the tank, up to about two-thirds of the height, there is a pipe that provides an exit.

- Garbage sits on the bottom due to the fact that it is carried to the periphery by centrifugal force.

- The airflow exits in the center.

- The smallest particles get into the engine in any case. Therefore, it is recommended to equip the container with a HEPA filter at the outlet. It's not worth saving. Otherwise, you will have to constantly lubricate the engine. If the vacuum cleaner sucks in water, it will end up in a barrel.

Such homemade vacuum cleaner great for a gardener. The unit can be made universal. For example, cut a barrel to fit the diameter of a tank with standard dimensions and equip the device with a van for movement. So you can clean up the whole park.

How to make a mini vacuum cleaner from a plastic bottle?

Today, almost every home has a computer. As you know, its body is periodically clogged with dust, which prevents the cooling of many parts. The circuits should be vacuumed from time to time. To facilitate the process, you can use a homemade mini-vacuum cleaner.

For the manufacture of the unit you need:

- fan from the computer;

- plastic bottle;

- hose;

- polystyrene;

- power supply 220 V/14 V;

- insulating tape;

- paralon.

Working process

- A plastic bottle is cut in half. The part that remains with the cork is taken. A filter is cut out of the foam rubber. It is inserted into the neck. The material must be tight.

- A hole is threaded through the cork into which the hose is inserted.

- The cork is screwed onto the bottle.

- A fan is taken from the computer (its corners are smoothed). It is inserted into the bottle in such a way that during operation the air flow rushes to the wide side of the bottle.

- The place where the cooler is located is wrapped with insulating tape. A wire is used for strong fixation.

- The power supply is connected to the fan. The red wire goes to the positive side, and the black wire goes to the negative side.

How to make an industrial vacuum cleaner with your own hands?

How to make an appointment? The basis of one of these units is the Ural PN-600 model.

You will need:

- Bulgarian;

- a pipe with a diameter of 4 cm and a length of 20 cm;

- plastic bucket with handle and lid;

- scotch;

- insulating tape;

- drill;

- self-tapping screws;

- glue;

- medical bandage.

Stages of work

- First of all, the Ural garbage collector should be finalized. For this purpose, the wheels are unscrewed from the bottom with a screwdriver. Holes are sealed with tape.

- Then you need a grinder, with which the latches and bartacks are removed. A plug is installed, rewound with insulating tape.

- A hole with a diameter of 43 mm is drilled in the bottom.

- Gaskets are cut out of the seal, the thickness of which is 4 mm.

- A gasket, a bucket lid and a centering pipe are placed in the waste container.

- Using a drill, a hole with a diameter of 2 mm is made.

- The cover is fixed with self-tapping screws 4.2x10 mm.

- An external hole is made for the suction pipe. It is planned at an angle of 15º. The hole is cut with scissors for metal.

- The pipe is fixed with self-tapping screws. For sealing, they use an ordinary medical bandage, which is impregnated with Titanium glue. The bandage is wound around the nozzle.

Second way

To assemble the unit in the second way, you will need:

- old home vacuum cleaner;

- oil based filter;

- bucket with a capacity of 20 liters with a tight-fitting lid;

- PP corners 90º and 45º with a diameter of 40 mm;

- meter of plastic pipe with a diameter of 45 mm (suitable corrugated pipe 2 m long and 40 mm in diameter).

Device assembly

- First, take the lid of the bucket. A hole is cut in it at an angle of 90º. Then a corner of the same size is inserted.

- When a corner is inserted into the lid, all the cracks are covered with glue using a construction gun.

- A slot is made in the side of the bucket, into which a 45º corner is inserted. All cracks are also covered with glue.

- To connect the corrugation to the corner, it is necessary to cut off a piece of pipe with a diameter of 40 mm. The corrugation should fit snugly. If it does not fit on the inlet pipe, then you can resort to using a siphon model on the kitchen sink.

- The narrow end of the corrugation is fitted to a forty-millimeter pipe. The other end is connected to the opening of the vacuum cleaner.

- To prolong the life of the filter, a nylon stocking should be pulled over it.

Can an old vacuum cleaner come in handy?

There is an old vacuum cleaner at home. What can be done from an unnecessary unit?

If the device works, then it can be used for another purpose. Some methods require technical training, since reworking equipment is dangerous. In particular, you should understand the principle of operation of motors.

This article will describe the safest methods.

Air blower

If you connect a hose to the outlet available in most models, you can get a unit for inflating rubber mattresses, pools for children and other similar things. At the same time, the vacuum cleaner container needs to be pre-cleaned from debris.

What can a Typhoon vacuum cleaner do?

What to do with an old Typhoon vacuum cleaner? The principle of operation of the unit is different high level performance.

The case of a Soviet-made vacuum cleaner is impossible better fit to create a device for grinding grass. It has a top opening of a suitable diameter. Typhoon is great option, but not the only one.

What else can be applied?

- The body of the device can be replaced by a container in the form of a cylinder. For example, a pan, a bucket, or a piece of pipe is used.

- The 180 watt motor is taken from an old washing machine.

- A hacksaw blade is used as knives. You will need a profile for the rack rectangular shape size 15x15 mm.

- The sleeve for attaching knives is machined on lathe. Its height is 40 mm.

- The engine with the pulley removed is attached to the container from below by means of studs.

- To clamp the knives, water nuts with a diameter of 32 mm are used.

- A hole is cut for the motor shaft.

- For reliable fixation on the shaft, a pair of holes with a diameter of 7 mm and an M8 thread for locking bolts is made in the sleeve.

- Platforms are machined on the reverse side of the motor shaft to increase the level of reliability of fastening the bushing with locking bolts.

Grain crusher manufacturing

To make a grain crusher, a person must have experience with machinery. Self-manufacturing devices without relevant knowledge is not recommended.

- Take a sheet of plywood square shape. An electric motor is fixed on it so that the shaft goes down by 40 mm.

- The steel plate is mounted on a threaded tail. It is fixed with nuts, bushings and washers.

- Leading edges are sharpened on both sides of the axle.

- The axial hole is made in the middle of the plate.

- To create a working chamber for the future unit, a body is made in the form of a ring. It is based on The correct design of the part involves bending the edges of the rings outward. They should form 10 mm flanges. It is with their help that the body is attached to the base. A sieve is screwed to them.

Making an attraction for children

What can be done from an old vacuum cleaner for children? If the motor of the unit is running, then it can be used for the attraction.

For this purpose, a tennis ball is pierced through with a pin, so that the ends of the pin are on both sides of the ball.

After that, the propeller is made. A jar made of polystyrene is used. The propeller is mounted on top of the ball. One lane is enough for him. It is cut with scissors.

The propeller is pierced in the middle and mounted on the axis of the pin. For speed and ease of rotation, it is advised to make bearings from beads. They are attached on both sides of the strip.

The top edge of the pin is bent in such a way that there is not much play on the axis.

Such a ball can be launched into the air through the outlet. If desired, the ball is decorated with sparkles.

Conclusion

This article described how to make a vacuum cleaner. There are many build options. It was also described what can be done from a vacuum cleaner.

Remember that without the appropriate technical knowledge, it is not worth getting down to business. It will be difficult to make a vacuum cleaner yourself in this case. It is better to seek help from a specialist.

To do this, we only need the most common rubbish that can be found in any apartment: broken appliances, electronics, wires, cut pipes, hoses and other “garbage” that you regretted throwing away. All this is useful to us to make a vacuum cleaner from a bottle with our own hands. Let's consider step by step how to do it.

First of all, you need to get somewhere a small working electric motor. Without it, everything else will remain useless trash.

Equipment often fails due to the breakdown of any one part, and everything else remains serviceable. Therefore, you can, for example, borrow a motor and other parts we need from your old cassette recorder, player, music center or children's toy.

To make a vacuum cleaner with your own hands, you need to prepare the following details:

- plastic bottle right size.

- Electric motor.

- Switch with wires.

- Power supply or batteries.

- Connector for the power supply.

- Flexible hose or tube.

Tools and consumables:

- Stationery knife.

- Soldering iron.

- Solder.

- Hot glue.

- Scissors.

- Tin can or bottle.

- Marker.

- Ruler.

- Stationery buttons.

- Nylon screed or thick wire.

- Small nylon mesh.

- Scotch, adhesive tape or a patch.

Training

At the very beginning, you should clearly define the goals that your homemade vacuum cleaner will have to fulfill. Some features of its design will depend on this. If we need it, then a battery-powered motor from a children's toy is quite suitable for this. If we are going to make something more serious (for example,), then the parts and materials used should be larger and stronger, respectively.

The most careful thing to do is to choose a motor and a power source for it. Their electrical characteristics must be exactly the same, otherwise problems may arise: one of the two will either burn out or simply will not work.

Step-by-step instruction

So, how to make a vacuum cleaner from a bottle? To do this, you need to clearly understand what it looks like and. We take an irregularly shaped plastic bottle and cut off the neck from it in the place where it expands. We should get something like a lid that can be tightly inserted back.

Then, from the cut of the neck, we measure the excess part and cut it off in such a way that the remaining volume is enough for the dust collector and the placement of the motor.

For the manufacture of a fan, any piece of soft metal of a suitable size is suitable for us. This could be the bottom of a can, a tin lid, or something that can be easily cut with scissors and then bent. Ideally, if we are lucky enough to find a ready-made propeller from some kind of toy.

The diameter of the fan impeller should almost match the inner diameter of the bottle for better suction.

Cut out a circle from a tin and mark it into eight equal parts. Next, along the marking lines, we make cuts with scissors, leaving about 5-10 mm to the center of the circle.

In the center we make a hole for the rotor of the motor, and slightly bend the impeller blades at an angle so that they suck in air during rotation, and not vice versa.

We fasten together the fan and the rotor of the electric motor with hot glue or in another way, trying to avoid distortions in the connection.

We make holes in the bottom for the exit of the air flow, simply cutting off the protruding edges of the bottom with a clerical knife.

Then you need to attach an electric motor to the inside of the bottom. To do this, we need any plastic cover. The main thing is that its size approximately coincides with the size of the motor.

This is necessary to securely glue the electric motor to the bottom of the bottle using hot glue.

A homemade vacuum cleaner is almost ready, it remains, which will separate the electric motor from the dust collection compartment. To do this, we use a fine mesh, which we stretch on a nylon screed or wire bent into a circle.

If the manufactured filter is tightly inserted into our homemade vacuum cleaner without additional fasteners, then you can leave everything like that. Otherwise, you need to fix it on the holders, which can be used push pins. The latter must be inserted into the bottle around the circumference at the place where the filter is attached and wrapped with adhesive tape on the outside.

For the manufacture of the hose, we use a tube with a diameter slightly smaller than the neck of the bottle. Several layers of medical plaster can be wound on the end of the tube so that the tube fits snugly into the neck and does not slip out of it.

Suction nozzles can be made from anything: from ballpoint pen, tubes from a dropper, syringe, plastic bottle - depending on their purpose. You can even use small replacement nozzles from a real vacuum if they fit.

Now it remains only to solve the issue of powering the electric motor, namely: connect a switch and a power source to it with wires, which can be batteries, a battery or a power adapter.

After that, our homemade vacuum cleaner is ready to use!

Conclusion

As you can see, making a small homemade vacuum cleaner or keyboard cleaner is not difficult at all. Moreover, the device made by us can be easily transferred from place to place not only within the apartment, but also used, for example, in the garage to clean the seats and panels in the car.