Installing a door in a wooden house: installation of plastic and metal structures, photos, videos and prices

It takes place in compliance with the technological features of the building design and the material from which the canvas and the box of the product are made. The process itself consists in dismantling the old and installing a new device. This is facilitated by the tool and the necessary fasteners.

For a more complete overview of how it is carried out, you can view the main technological steps in the video:

To work, you need a standard set of equipment:

- Nail puller.

- Saw.

- Chisel.

- Measuring equipment.

- Anchors, self-tapping screws, steel bars.

- Mounting foam.

It can be made with an independent purchase of hardware, if it is not provided for by the set of anchor bolts. The selection of hardware products with a length of 15 cm can be done independently. The thickness of the products is 12-15mm.

Dismantling the old door

- In the presence of collapsible loops, the product is hooked in the open position with a crowbar or other lever. So the canvas will rise and jump off the hinges.

- Installation of an iron door in a wooden house with non-separable hinges begins with unscrewing the screws holding the canvas in the box. This will be done with a screwdriver or screwdriver.

- The empty box is dismantled by unscrewing the fasteners (self-tapping screws, anchors, nails). If there are difficulties with taking it out, the side racks are sawn and torn off with a crowbar. Both parts are then removed.

- The installation of a steel door in a wooden house can begin with the dismantling of a metal or wood box attached to the opening with anchors, the elements are sawn off with a grinder, like metal racks. The opening is being cleaned of old thermal insulation, plaster residues, old clamps, etc.

- Regardless of whether plastic doors are being installed in a wooden house or metal ones, a properly prepared doorway for a new door should be several cm larger than the box. This helps to drive the blades and align the product in the opening. If the dimensions do not match, it is necessary to expand the passage with a grinder or supplement the structure with separate bars.

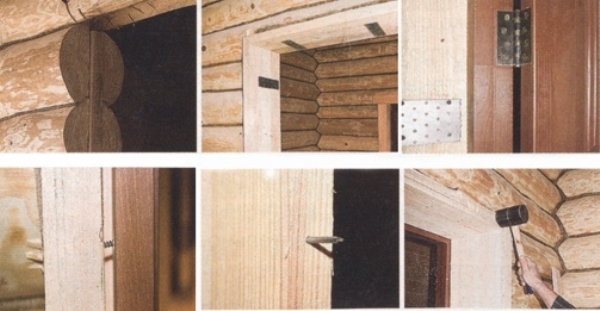

Box fixing

There are 2 fixation technologies:

- Through the mounting gaps in the profile part of the box.

- With mounting plates.

The installation of the box through the gaps in the profile structure is carried out provided that the thickness of the walls reaches up to 16-28 cm.

Installation of a box without a canvas is carried out by placing it in an opening. Blades from an array are laid under it, necessary to correct its position and create mounting holes.

After adjusting the position of the box, it is possible to drill gaps in the wall through pre-created voids in the profile installation: in depth - 15-20 cm. Anchors are inserted into the drilled nests, the position of the racks is checked. The correct position contributes to the twisting of the anchors and decorating with special plugs.

Then the hinges are lubricated, the door is mounted and the components are fixed. In the covered state, the canvas is checked for the presence and compliance with the specified dimensions of the gaps, which should be 4 mm.

Check the operation of the locking system. Inaccuracy detection is corrected by wedges. Drill out the gaps for the second rack. The smooth running of the door and locking devices is checked.

The mounting holes between the box and the wall are filled with building foam, which takes 24 hours to dry. The remaining parts of the foam are cut off, and the wall is puttied.

Installing the door on the plates

Typically, products arrive at the object with existing plates equipped with clearances for fasteners. It remains only to weld them to the box.

Important! Timber structures shrink. In the opening of the end wall, vertical grooves filled with tow are created. Here are placed bars for sliding. The number of grooves is equal to the number of fixation points.

A special casing is installed in the opening, fixed to the sliding bars with the help of self-tapping screws. The gaps on the uprights are 2 cm, on the horizontal bars - 7 cm. This prevents the door from jamming from shrinkage. The resulting gaps contribute to the free movement of the beam without exerting pressure on the door. This is especially important when arranging a new building. Later formed spaces are decorated with platbands. They can be made from wood and metal.

Installation of plastic doors: Preparation

The whole preparation process is carried out in several steps:

- The opening is adjusted. The passage is cleared of crumbling plaster, various kinds of pollution are removed.

- The doors are dismantled. In this case, you can separate the canvas from the box.

- Mounted fasteners. This is facilitated by special brackets placed on the back side of the box in a special groove or by means of anchors installed through the box. In this case, it is important to pre-drill the gaps. Brackets and holes are equipped with 3 pcs. at both sides.

- A few nails are hammered into the opening or a similar number of self-tapping screws necessary for the stop is twisted. Based on the thickness of the box, marks are created on the side parts of the opening at the top and 2 stops are placed in these areas. 2 screws are screwed or dowels are hammered. A similar process is provided in the lower part of the opening - 4 hammered dowels set the mounting plane of the door structure.

Box fixing

Door fastening is carried out by 2 methods. The difference lies in the presence or absence of brackets. In the first version, the products hide the slopes. Mounting process:

The door is inserted into the passage and leans on the dowels placed at the top of the opening. The box is placed on a slope. Along the edges of the box should remain the same gap to the opening.

2-3 wedges are prepared with fasteners, a hammer and a perforator. The level is placed on the threshold. Wedges driven under the threshold are clogged. This aligns the structure.

The blades, placed on the sides of the box, fix the door at the top of the opening, and then at the bottom. The box should be tightly pressed against the 4 stops (dowels placed in the passage).

Using a puncher, gaps are drilled and fasteners are mounted. The beginning of the process is carried out from the side of the canopies. After inserting dowels or screws on both sides, do not rush to tighten them. Rigid fixation of the box is made at the end of installation. During operation, it is important to ensure that anchors, dowels or self-tapping screws do not bend the profile of the box.