Door hinge dimensions, tolerances, markings and some requirements

Despite the fact that door hinges are partly visible fittings, their choice should be given no less attention than locks and handles. The durability and comfort of door operation depend on the structural reliability of the hinges, but their decorative component is no less important. One can hardly argue with the fact that an elegant canvas with coarse hinged plates will look elegant only until someone opens the sash. The same effect can occur if the dimensions of the hinges in relation to the dimensions of the door turn out to be visually incommensurable.

To universalize hardware, manufacturers in the manufacture of products adhere to standardized linear parameters of component parts in accordance with GOST 5088-2005, although, if necessary, design documentation can be developed that defines other sizes for door hinges and the shape of the hinge card. Most often, this happens when an exclusive range of products is released or when ordering an individual batch of goods. But this requires the approval of responsible organizations.

Short review

Only thanks to the door hinges does the opening and closing of the hinged doors occur. The sizes and quantity of products are chosen depending on three main factors:- canvas weight;

- door installation locations;

- block material.

According to the standards, the separation of door hinges by the mass of the sash is carried out in the following gradation:

- light - installed with a weight of canvases up to 60 kg;

- medium - more than 61kg, but less than 120kg;

- massive - starting from 121kg and ending with 250kg;

- special - more than 251kg.

The standard dimensions of the door involve the placement of two hinge mechanisms in height, but with a large mass or height of the canvases, it is allowed to install three, four and even five hinges on one leaf of the door unit. Sometimes this technique is used by designers as an element of interior design, although such fantasies cause some difficulties in implementation.

According to the method of installing door hinges on the canvas and the box, the products are divided into several groups:

- mortise;

- invoices;

- hidden;

- corner;

- double;

- screw;

- combined.

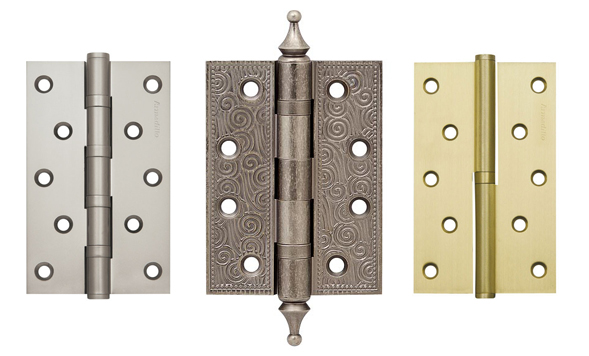

In addition, they are one-sided (left or right) and universal. Loop cards, for the most part, have a rectangular shape, but the outlines of exclusive models may differ in complex ornate lines.

As the main materials in the manufacture of hardware, ordinary and stainless steel, aluminum alloys and brass are used. The surface of elements and parts made of metals that are not resistant to corrosion is protected by various decorative coatings “under” gold, silver, bronze, copper.

Dimensions and tolerances

The most common are card loops of the overhead or mortise type. They are not as aesthetically pleasing as more modern types of hardware, but they continue to be in demand, and therefore their production is unlikely to stop any time soon. Today, manufacturers offer a wide range of products, including models made in the old style.

Structurally, the loops consist of two elements, called plates or cards, which determine the dimensions of the product. Concepts such as the height, width, and thickness of door hinges are associated with the corresponding indicators of the hinge map. Orientation to the length of the axial rod is incorrect, since quite often decorative caps are installed on both sides of it. They only visually increase the element, in no way affecting the functionality of the card loop. The dimensions of the screw-in mechanism are determined by the height of its cylinder in assembled form.

- height - 110, 130, 150mm;

- width - 27, 30, 35mm;

- thickness - 2.5; 2.8; 3.0mm.

Products with a height of 110mm on each of the cards have four holes for screws, while the other two copies (130 and 150mm) have five through holes in the plates. The increased number of holes makes it possible to secure the hinge assembly more securely.

It should be noted that only one size is indicated in the marking of door hinges - their height in millimeters.

The hinge mechanism enables the door to open and close, rotating around its core part. One of the hardware cards has a cylinder (tube) that fits into the stem (axle) of the other plate. Most of the tolerances in size are associated with this particular feature of the door hinges. In particular, this applies to:

- gaps in places of movable connections between the rod (axis, semi-axis) and the tube - within 0.1 ... 0.5 mm;

- gaps between the cylinder and the card surface - less than 1 mm with a plate thickness of more than 2.2 mm;

- ovality of the rods - no more than 0.1 mm;

- tube ovality - no more than 0.3 mm;

- perpendicularity of the cylinder sections in the bearing part of the hinge and the reference surface itself relative to the axis of rotation - no more than 0.25 mm;

- backlashes in the hinges in the longitudinal and transverse directions - no more than 0.3 mm.

![]()

Hinges have been installed on the door since time immemorial, but in ancient times they were larger in size, and many of them were not very elegant. Details were forged from iron strips, and symmetry was not a priority in the manufacture of products. But manual work contributed to the diversity and ornate forms of loops unusual for us. Many of them were real works of art, which forging masters are trying to revive when creating unique retro design projects. The dimensions of the parts, in this case, are selected individually.

Marking for door hinges

The optimal dimensions of the indentation of the hinges from the upper and lower ends of the door leaf are 250 mm. If additional canopies are provided on the door block, then, as a rule, they are moved away from neighboring cards by at least 250 mm.

The third hinge on the door can be installed at the same distance from the extreme canopies, but for better load distribution, it would be more correct to place it closer to the upper hinge.

Some Requirements

Hinges are an important element of the door block, so they must be strong and reliable in order to withstand numerous opening and closing cycles of canvases. One of the fundamental points that affect the duration of operation of doors is the possibility of repairing, adjusting or replacing hardware. In this case, the interchangeability of door hinges due to the versatility of their sizes plays an important role.

As for the requirements for the products in question, they belong to several categories:

- constructive;

- strength;

- operational;

- decorative.

Door hinges must be of high quality, and their design must not allow spontaneous separation of the elements after the doors are installed in the design position. They must ensure reliable fastening of the leaf to the door frame and ensure a smooth movement of the sash - without shocks, jamming and squeaks. The products should be installed in such a way that their dismantling from the outside is completely excluded.

Hinge mechanisms are most susceptible to operational loads involving cyclic action. Manufacturers are trying to increase their reliability while increasing the number of trouble-free opening-closing cycles. Periodic lubrication of door hinges helps to get rid of many problems and facilitate the movement of the sash. But it is worth noting that not all modern models need it.

In order for the doors to look aesthetically pleasing, the fittings installed on all blocks within the common room must be in harmony with each other.

Designers do not recommend installing what is at hand on door blocks. The apparent invisibility of the loops is deceptive and can, at the most inopportune moment, expose the owner's "bad taste", making him blush in front of respected guests. Stainless steel hinges, for example, will stand out from the overall picture against the background of copper-plated handles, and looped cards that are too large in size will turn out to be an unsuccessful solution for combining them with a miniature and elegant handle. The external attractiveness of the hardware is given by protective and decorative coatings. All fittings must match each other in style, color and size.