Door seals and their installation

The functions of the door block include not only protection against the entry of unwanted guests into the house, but also protection from cold or hot air, odors and noise. There are always gaps in the places where the canvas adjoins the door frame, and seals are used to stop the movement of air through the gaps. Not so long ago, our parents and grandfathers used various auxiliary materials for this - rags, felt, moss and even straw. Today, technological progress has replaced these artisanal methods with more efficient and durable ones.

Purpose of door seals

Understanding why seals are installed on the door can be quite simple. Suffice it to recall the refrigerator that is in every home. What would happen if there was no rubber strip on the door? The answer is obvious - this is tantamount to the fact that the door would remain open, the effect of cooling the products would have to wait a very long time. The internal cold air was constantly mixed with warm air, as a result, the refrigerator would turn into an air conditioner that lowers the temperature in the kitchen. To localize the cooling zone, it is necessary to stop the air circulation. This task is performed by a rubber seal.

Similar processes occur with entrance and interior doors. The door leaf is adjacent to the frame with a technological gap of 3–4 mm, otherwise the door simply will not open. Through it, air can freely penetrate both in one direction and in the other. If this does not play a special role for internal doorways, then a stream of either cold or hot, sultry air will move through the entrance doors all year round. In winter, cold drafts will begin to blow inside the hallway, freezing will intensify. In summer, hot air from the street will appear in the house, and at the same time dust and noise.

According to experts, from 25 to 30% of heat is lost through the front door without sealing in the cold season. The solution to all problems is an elastic seal that seals the gaps inside the door unit and allows you to control the movement of air.

Air chambers inside the seal increase its thermal insulation properties

Types of door seals

For ease of selection, seals are classified according to the following criteria:

- according to the material of manufacture (there are rubber, plastic, silicone, foam and polyurethane);

- according to the intended purpose (for entrance doors or for interior doors);

- according to the installation method (fixation on glue or in a special groove).

Rubber

Rubber seals are time-tested and are most often used for entrance doors. Rubber vulcanized in a special way endures not only moisture, but also a wide range of temperature fluctuations (from -60 to +90 o C). Possible installation options:

Silicone

An analogue of a rubber seal adapted for interior doors. It is characterized by softness in operation and a lower price, since its resistance to mechanical stress is lower. It is used for lightweight doors made of wood and its derivatives - fiberboard, plywood, chipboard, etc.

Silicone seals are installed mainly on interior doors

Foam seals

Foam rubber is the most inexpensive and short-lived type of door seal. Service life - a year, at most two. With intensive use, the material quickly deforms (compresses and breaks), so that the sealing has to be updated almost every season. Foam rubber is more suitable for warming deaf window frames. However, the low price allows you to change the seal as often as you like. The disadvantage is the ability of the porous material to absorb moisture with all the ensuing consequences - freezing and deformation of the junction of the doors with the frame.

The foam seal is available in the form of a twisted bundle of various widths.

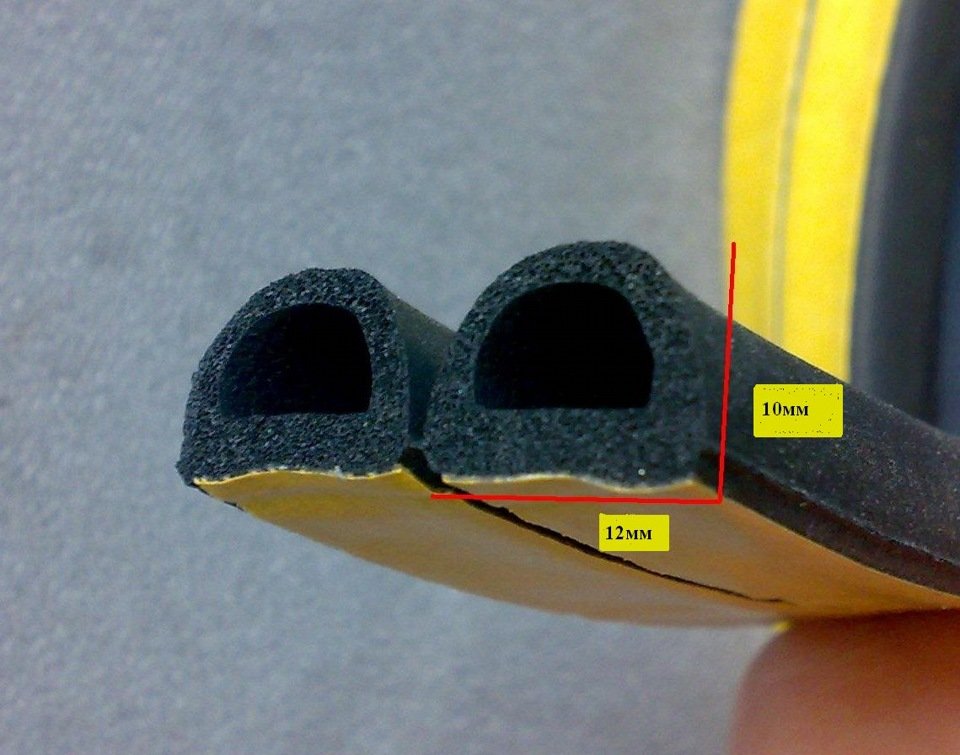

Polyurethane

Polyurethane seals are used in sliding doors (compartment, book, sliding, etc.). Their purpose is to minimize gaps, as well as mitigate impacts. The design feature is that inside the elastic body there is a filler made of foamed polyurethane. Seals have a long service life and are designed for 15–20 years of service (more than 300,000 opening cycles). They are also used for plastic windows and doors, as they withstand UV radiation. The main disadvantage is the high price.

Polyurethane seals are used in structures exposed to solar radiation

Brush

Relatively new product that emerged with the development of sliding doors. The adjoining of the canvas to the frame is not always so even as to qualitatively install a rubber seal. In these cases, a flexible nylon bristled brush construction is used to close misconfigured gaps. Such seals are successfully used for revolving and sliding doors (and not only interior and entrance doors, but also automobile ones). Especially often they are installed on thresholds - where dust accumulates most of all. During the movement of the blade, the brushes “rake out” the debris and clean the guide track from contamination. Manufacturers claim (and not without reason) that such a sealant is effective in combating dust and freezing. Although its sound transmission is, of course, much higher than that of rubber.

The brush seal is easy to install and slows down the movement of air in the lower part of the doorway

Magnetic

Magnetic seals are predominantly used in metal entry doors where sealing is critical to keeping the house warm. The design of the seal includes a rubber housing and a magnet built into it around the entire perimeter. The force of attraction makes the sash tightly pressed against the door frame, thanks to which the smallest gaps are leveled. In each case, it is important to choose the right magnetic seal: a weak attraction will not work effectively enough, and an excessive one will create difficulties when opening the door. As a sample, you can take the effort to open the refrigerator door - it is with this force that the magnet must hold the door closed.

The magnetic strip embedded inside the seal has an unlimited service life

Sealing the room with a magnetic seal has received the highest marks from experts. Air from the outside, as well as noise and fine dust, practically does not penetrate into the room. Service life - from 15 years and above (depending on the quality of the rubber band). During operation, it is necessary to ensure that small metal objects do not get between the leaf and the door frame, especially steel shavings with sharp edges are dangerous. The outer rubber gasket must be washed and cleaned of adhering debris at least once a month (the magnet attracts not only metal, but also small electrostatically charged objects).

The bulk of household door seals are unified for self-installation. The only exceptions are magnetic gaskets, it is better to entrust their installation to specialists. Fastening is carried out using glue or a special groove machined in the door block. For domestic use, self-adhesive tapes are widely used, the surface of which is covered with a moisture-resistant adhesive with a protective film.

When selecting a ready-made factory seal, attention should be paid to the following parameters:

- tape thickness;

- pad width;

- fastening method.

From myself I would like to add. There is an old grandfather method that is still relevant today. To determine the thickness of the seal, wrap a piece of soft plasticine (or raw rubber) in a plastic bag and clamp it into the door in several (at least four) places. It is possible that in the area of \u200b\u200bthe hinges, the compression will be stronger, and less near the door handle. According to the print on the plasticine, the maximum and minimum seal sizes are determined, and then the average value is found. For example, at the hinges, the plasticine shrank to 3 mm, and in the opposite corner - to 4 mm. This means that you need to install a tape with a minimum thickness of 3.5 mm.

It is believed that in normal operation, the gasket is compressed no more than 50% in thickness.

As for the width of the tape, everything is simple here. It should not exceed the width of the supporting part of the door jamb - when the door is closed, it should not be visible from the outside.

The method of fixation is determined as a result of a visual inspection of the door block. If there is no recess for mounting the seal in the frame or canvas, then the fastening is carried out with glue. If a thin (from 3 to 5 mm) groove is selected around the entire perimeter, the door is designed for a groove seal.

The compression of the seal should not exceed half of its thickness.

Installation and replacement of the seal on various types of doors

The tool needed for self-assembly is simple and can be found in every home:

- pencil or marker;

- tape measure and ruler;

- sharp knife;

- a brush with a long (2-3 cm) pile.

To install brush seals, you will additionally need a hacksaw for metal.

The glue used is waterproof, best of all - rubber. For degreasing and cleaning the edge of the door, acetone solvents and sandpaper are used.

When working with a solvent, it is necessary to protect the respiratory organs from toxic fumes with a respirator

If the old seal is being replaced, it is necessary to remove the used tape from the doors and carefully treat the surface with fine emery. Before sticking the tape directly, the end of the frame (or canvas) is washed and degreased. Small tubercles are ground down, and small depressions are puttied (pre-filled with glue and dried).

Depending on the type of gasket, there are certain installation nuances. After reviewing them, everyone will be able to install a thermal insulating tape on their door on their own.

Sealing metal doors

Since the metal door has a smooth surface, self-adhesive or simply adhesive seals are most often used. The sequence of actions in this case is as follows:

The main mistake when working with silicone and rubber products is excessive tape tension. It is impossible to stretch the gasket during installation; it must be laid in a free, “relaxed” state.

Video: how to properly glue the seal on the front iron door

Installation of a sealant in wooden doors

The seal is mounted on a wooden base in two ways - on glue (we examined it above) and in a groove. The second method is considered more reliable. The procedure for installing the seal in this case is as follows:

When preparing a wooden door for sealing, do not over-moisten the material. Glue will very quickly lag behind raw wood. If moisture still gets on the canvas or frame, you must wait until the wood is completely dry and only then glue the sealant. To speed up drying, use a building hair dryer.

Installing a seal in a plastic door

Plastic doors are equipped with seals at the manufacturing stage. In domestic conditions, the replacement of a used part is more often relevant. The design of the doors has a special ebb (groove) for installing the seal on the glue. Therefore, to replace you need:

Installation of brush seals in sliding doors

Sliding doors are most often equipped with brush seals. Sometimes they are also called antithresholds. Due to the design features, the installation of brushes differs from the installation of rubber and silicone gaskets. They are mounted at the bottom of the door or (less often) at the side end.

The installation scheme is very simple. If the door has a flat and smooth surface, the brushes are glued to double-sided tape. If there is any doubt about the strength of the adhesive layer, fixation can be further strengthened with screws. The steps for installing a brush seal are as follows:

Some models of brushes are attached using brush holders - special metal or plastic profiles. Most often they are used on doors with large dimensions - in garages, warehouses, etc. In this case, the mounting profile is first installed, and then the brushes themselves are attached to it.