Do-it-yourself slate fence construction

Profiled pipes are a popular material from which all kinds of structures can be made, including fences. Fences, gates, gates are made from a profile pipe. This material, with proper installation, provides reliable protection of the protected area. Moreover, it is quite possible to do all the work with your own hands, which allows you to significantly save on construction work. Let us analyze in more detail how gates from a professional pipe are correctly manufactured and installed, as well as the features of these structures.

Gate from a professional pipe of a pipe

Why profiled pipe?

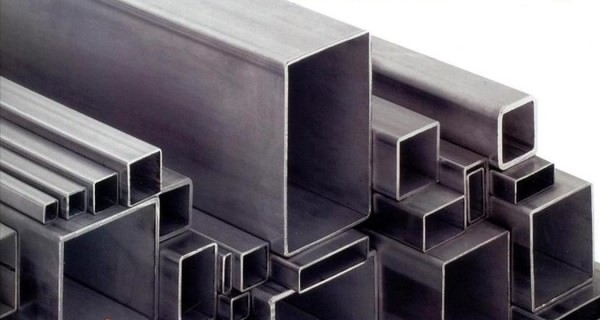

Variety of stainless steel profile pipes

Variety of stainless steel profile pipes We indicate a number of advantages of a profile pipe in comparison with similar materials for the manufacture of gates and gates:

- Gates and gates from a profile pipe have a simple design, so they can be made and installed by hand.

- The material is light in weight, so there is no need to equip the foundation. Usually it is enough to concrete only the supporting pillars.

- The durability of such a fence is calculated in decades.

- Gates and gates are strong and reliable. The metal profile provides sufficient rigidity.

- The cost of a profile pipe is relatively small.

- The lock is easily installed on the metal profile.

- If desired, you can veneer such fences with any material with your own hands. For example, corrugated board, polycarbonate or metal sheets.

Materials for the manufacture of gates

To make a structure from a profile pipe with your own hands, you will need the following materials:

- Support pillars. Their length must exceed the estimated height of the structure by 1 m. At this length, the posts will be buried in the ground. If shaped pipes are used as supports, then their cross section must be at least 60 x 60 mm. If the wicket and gate are mounted at the same time, then all 3 supports are installed immediately.

- Profile pipe with a section of 20 x 40 mm for the frame.

- Corners with side dimensions 40 x 40 mm for lintels. You can use the same pipe from which the frame is made.

- Loops for a canopy of a framework.

- Thick metal for making loops on which the lock will be hung.

- Primer and paint for pipes.

- The lock that will be installed on the frame.

- Building materials for concreting supporting pillars.

Necessary tools for work

To make and install a gate, you will need the following tools:

- Bulgarian for cutting metal pipes.

- Welding machine, through which it will be possible to weld the frame of the gate, as well as weld the hinges to the poles.

- Construction level.

- Roulette, chalk, pencil.

- Shovel.

Preparatory work

The first step is to install the support pillars to which the gate will be attached. The standard distance between the pillars is 1 m. For their installation, holes are dug with a depth of about 1 m. The pillars are placed in the holes, according to the level, after which they are concreted. This work does not present any difficulties, so it is done very quickly with your own hands. After concreting, it is necessary to wait a few days to allow the concrete to fully cure. If you hurry up and do all the work in a couple of days, the design can “lead”.

If metal supports are not provided for in the design, then brick pillars are made. In the process of their installation, it is necessary to insert metal mortgages into the masonry to fasten the frame.

Making a gate from a profile pipe

Knowing the exact size of the opening between the supporting pillars, you can begin to manufacture the wicket frame. We will not consider the gate, since this is the topic of a separate article.

It is required to weld a frame from a profile pipe. This must be done on a level surface to ensure that the structure is level. The work is done in the following order:

- Pipes are cut according to the required dimensions. Joints between individual segments are recommended to be connected at an angle of 45 degrees.

- The cut parts are laid out on a flat surface, after which they are pressed against it with some kind of rigid mount.

- Now you can weld the pipes together. Welding is done in a spot way.

- To ensure the rigidity of the frame, it is necessary to install spacers. If the gate is transparent, then longitudinal rods are welded between the bottom and top of the frame.

- Swivel hinges with pins are welded to the frame. If a padlock will be installed on the gate, then it is also necessary to weld eyelets for it.

- All burrs are cleaned with a grinder.

In the process of manufacturing the frame, consider its dimensions. Ensure a gap between the gate leaf and the soil of at least 10 cm. It is necessary for the free opening of the sash in winter, when a layer of snow lies on the ground. It is quite easy to weld such a frame with your own hands, if you have at least small skills in plumbing and welding.

Wicket installation procedure

It was the turn to hang the gate on the supporting pillars. It is recommended to do it yourself in the following sequence:

- Previously, the gate is checked by applying it to the opening. It is required to fix the frame in the opening. The easiest way to do this is with tacks, which are welded to the frame of the gate and to the supporting pillars.

- Weld blind loops with holes to the support post.

- A groove is cut in the pipe wall into which a mortise lock will be inserted. If the lock is a padlock, the groove does not need to be cut, however, it will be necessary to weld the fasteners for the lock.

- A hole for the bolt of the lock is also cut in the support post or the corner welded to it.

- Temporary tacks are cut off by a grinder.

- The door is being tested. If the hinges are fixed without distortions, then after cutting off the tacks, the gate will move freely on its hinges.

- The frame is removed from the hinges, after which the hinges are filled with grease.

- The frame is again hung on the hinges.

- The frame is primed and then covered with two coats of paint. If a gate is mounted together with a gate, the priming and painting of these structures is carried out simultaneously.

- The prepared lock is installed.

Gate installation completed. The frame is sheathed with the selected material. If the gate and the gate are closed with corrugated board or sheet metal, these materials are fastened to the profile pipes using a rivet gun. If the facing material is not used, decorative elements are attached to the openings.