Step-by-step instructions for making a gate from a profile pipe with your own hands

The visiting card of the owner of a summer cottage or a country cottage is a gate that should look representative and aesthetically pleasing and, at the same time, reliably protect the entrance to a private territory. These indicators are fully met by swing or retractable types of structures made of a profile section pipe - an affordable, inexpensive and easily processed material. By adhering to the step-by-step instructions and the developed documentation, you can make and install swing gates with your own hands at minimal cost, as well as decorate them.

Profile pipe as a material for gates - pros and cons

The profile pipe, used as the main material for the manufacture of gate structures, is deservedly preferred due to its many advantages.

Profile pipes are widely used for the manufacture of gates.

The main advantages of using a profiled pipe for the construction of gates:

- low costs for the acquisition of material;

- high structural strength;

- convenience of screwing in self-tapping screws for metal;

- aesthetic appearance of the frames;

- light weight of the metal structure;

- ease of processing and welding of workpieces.

Along with a complex of positive aspects, the profile pipe also has weaknesses:

- susceptibility to corrosion caused by operation in conditions of high humidity and the penetration of moisture into the profile pipe;

- the occurrence of deformations of the frame during operation, due to the use of threaded fasteners during assembly;

- the inconvenience of applying a primer and paint on the surface of a profile pipe, which slightly increases the duration of work.

Compliance with the manufacturing and installation technology of the gate minimizes the likelihood of negative factors and guarantees a long service life of the product.

Preparation for manufacturing: how to calculate the dimensions of the future design

Despite the simplicity of manufacturing the metal structure of the gate, at the design stage it is important to responsibly approach the implementation of preparatory measures, carefully consider all the nuances. A serious approach will allow you to avoid mistakes and correctly calculate the dimensions of the future structure.

To calculate the dimensions of the product at the design stage, it is necessary to consider the following points:

According to the previously developed drawing, the total footage of the profiled pipe and the required amount of material for sheathing are determined.

When designing a structure, the following points should be considered:

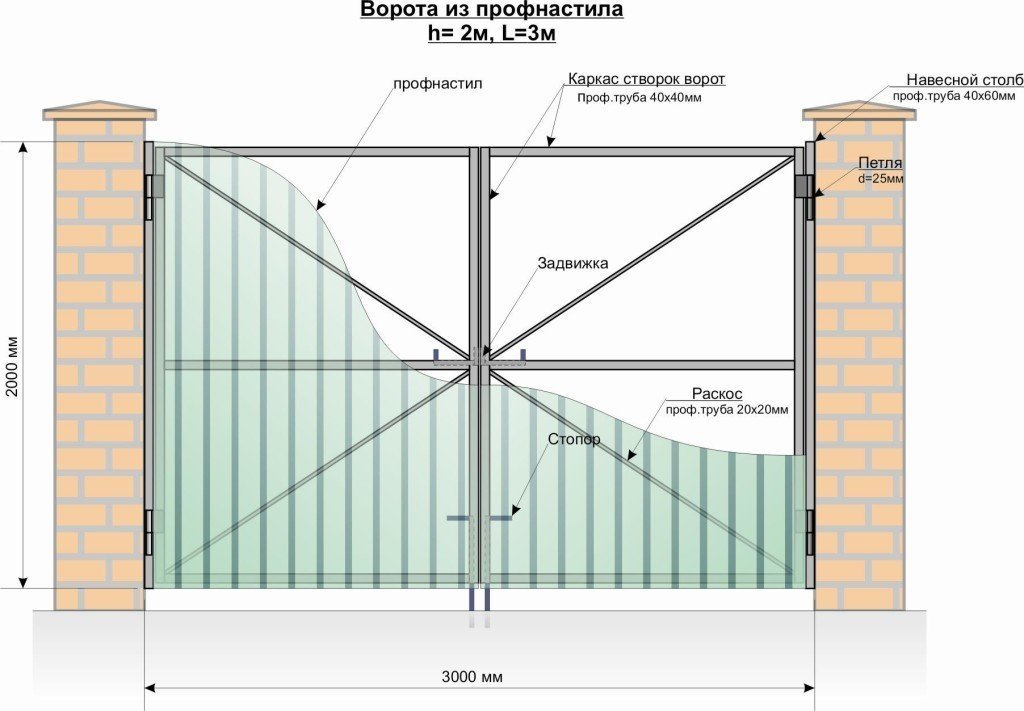

You can use a ready-made drawing and adapt it to specific conditions , with actual dimensions.

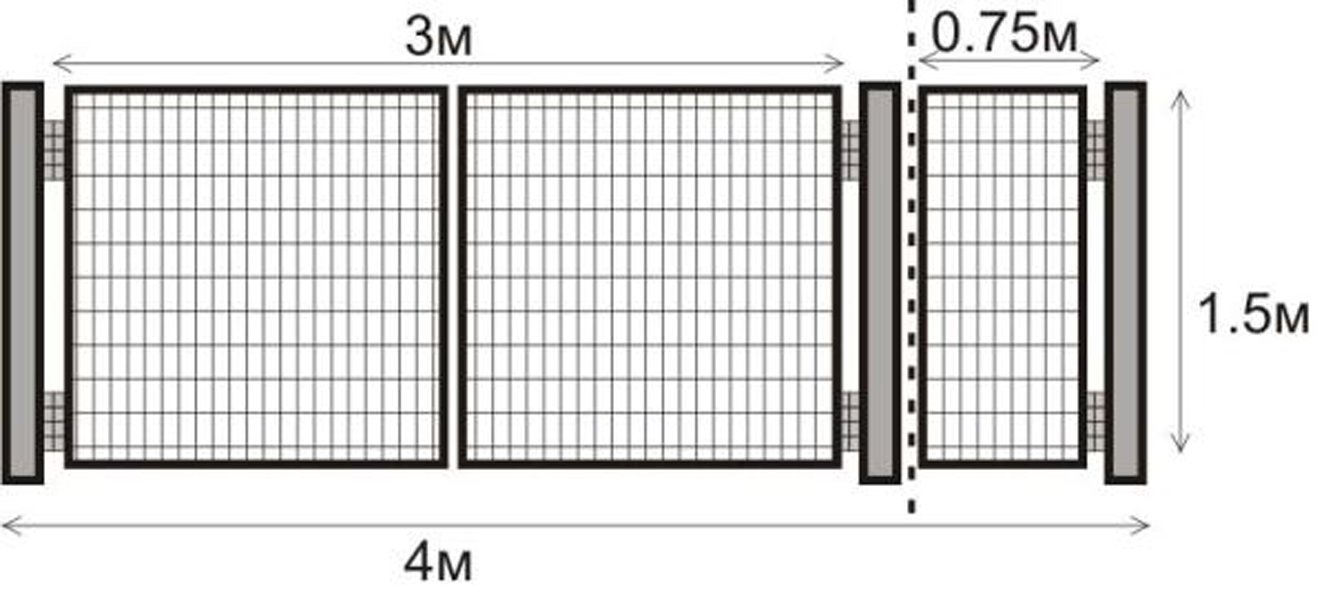

The standard drawing of a gate with a wicket door shows specific dimensions

To determine the distance between the supporting pillars, it is necessary to sum up the dimensions of the door leaves, the gaps for fastening the hinges and turning the leaves. The distance between the supports for the above option will be 2 + 2 + 0.01 + 0.01 = 4.02 meters.

Having decided to use a pipe with a profile section for manufacturing, you should decide on the assortment, type and size of rolled pipe. When choosing, consider the following points:

After analyzing the selection criteria, one can confidently give preference to welded cold-rolled pipes with a wall thickness of 2 mm square (25x25 or 30x30) or rectangular (20x40) section. Having selected the profile pipes, proceed to the calculations.

Calculation and necessary tools

Having decided on the size of the profile pipe and having correctly developed the drawing, you can begin to determine the need for materials, purchase purchased components, prepare tools and equipment for construction.

A generalized list of materials for the manufacture of gates includes:

- profile section pipes corresponding to the drawing dimensions;

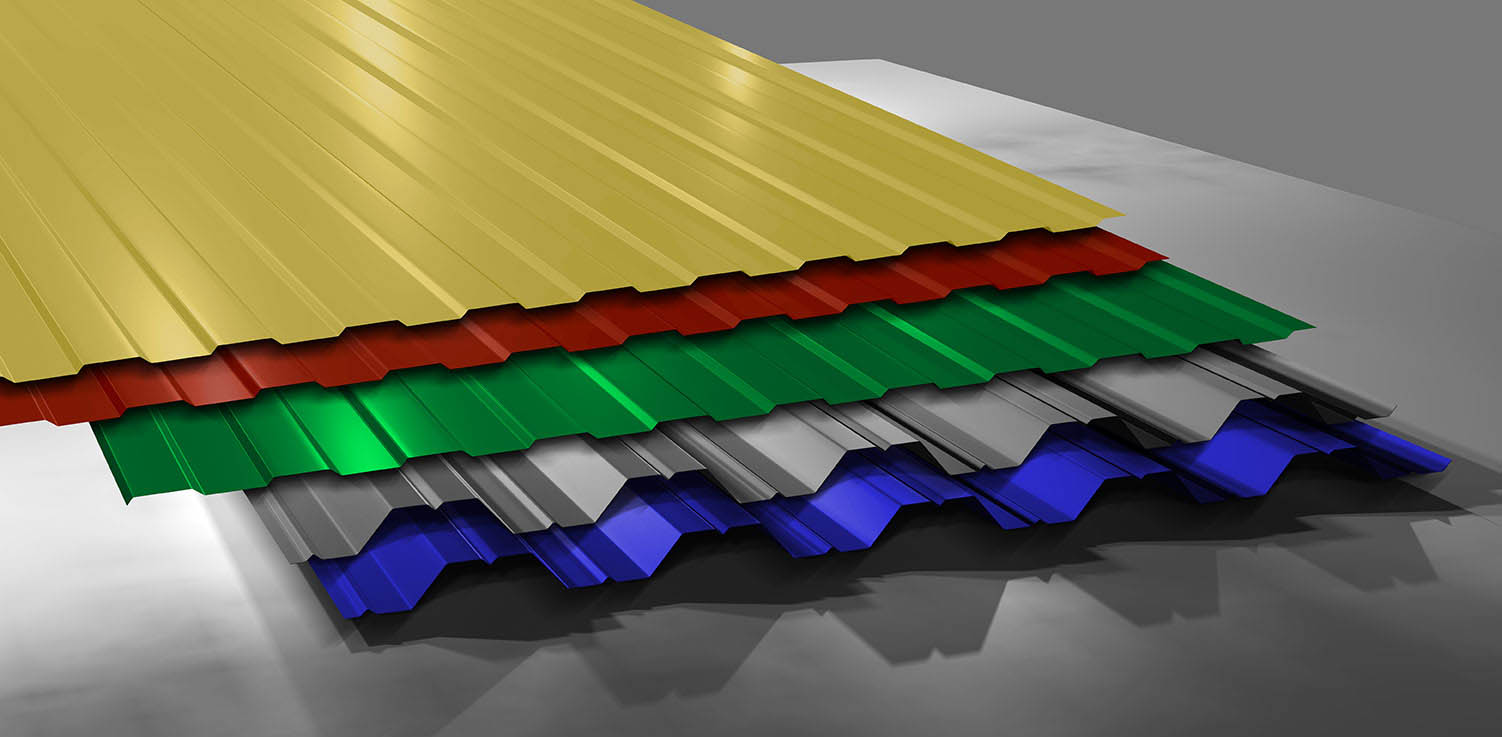

- sheathing material that will be attached to the canvases, for example, a profile sheet, polycarbonate, wood or metal;

- hanging loops for connecting canvases with support pillars or a roller mechanism for sliding gates;

- lock and elements for fixing the canvases (staples, hecks, latches);

- fasteners designed to fix the finishing material;

- decorative details (for example, forged elements), if they are provided for by the drawing;

- primer for corrosion protection and pre-painting of metal structures;

- enamel for exterior work, intended for final finishing and ensuring the presentation of the product.

On the example of a swing gate with two wings, we will calculate the need for materials.

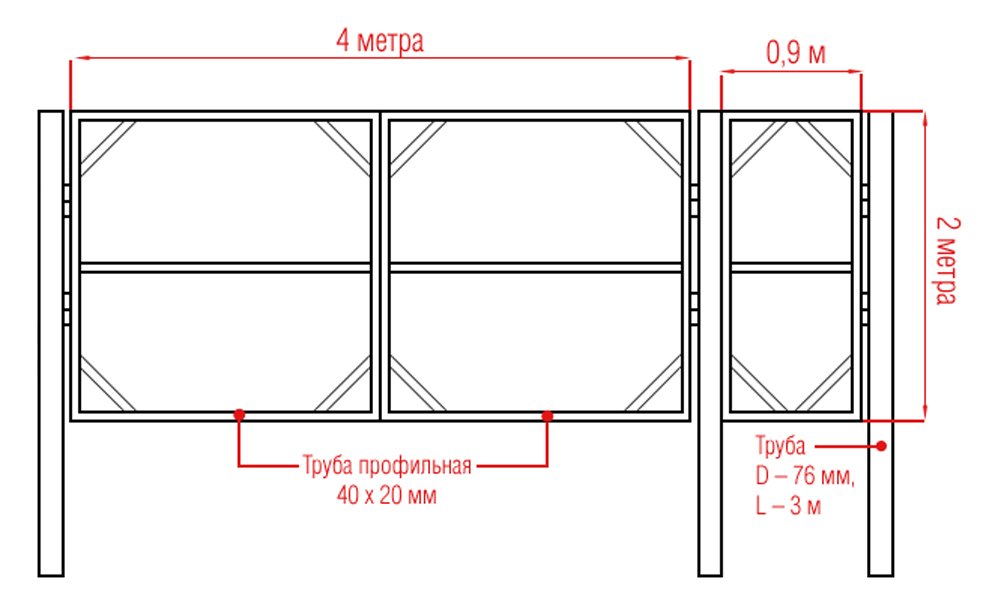

The determination of the need for materials is carried out according to the sketch with dimensions

For the gate shown in the sketch, you will need:

A typical set of tools for the manufacture of gates, installation and concreting of support pillars is slightly different.

To perform the work, it is necessary to prepare equipment and tools

For the gates we are considering, the following equipment and tools are required:

- welding machine with electrodes with a diameter of 3 mm;

- grinder with a circle for cutting metal;

- electric drill with drills;

- a hammer;

- tools for taking measurements, controlling the accuracy of manufacturing and assembly (tape measure, level, corner);

- grinding wheel for sealing welds;

- file to remove burrs;

- brush for applying a protective coating.

Step-by-step instructions for making a gate from a profile pipe with your own hands

In the manufacture of gates, follow the previously developed documentation and follow the technological sequence of operations.

Gates can be made from a profile pipe using welding equipment or using threaded fasteners.

Let's consider both options.

Welded construction

When welding swing gates from profile pipes, perform work according to the sequence:

Remember to correctly fasten the hinges corresponding to the opening direction of the gate.

The welded construction of the gate is characterized by increased strength.

How to weld a gate frame from a professional pipe with your own hands: video

The video shows in detail the sequence of work on welding the frame of the gate.

Threaded version

If there is no welding machine or there are no skills in handling it, it is possible to assemble the gate from a profile pipe without welding. To do this, it is necessary to use bolts, nuts with M8 thread and washers, as well as connecting elements.

Use of unified connectors simplifies assembly

Remember that the use of spring washers will prevent spontaneous unscrewing and increase the reliability of threaded connections.

To complete the assembly, you will need a drill with drills corresponding to the diameter of the hardware used, as well as wrenches.

The algorithm for manufacturing a structure without welding is completely similar to the previously given sequence for a welded product, with the exception of the following points:

During the operation of the gate, made without welding and assembled on bolts, the threaded fastening is gradually weakened. To ensure the rigidity of the structure, it is necessary to periodically check the degree of tightening.

After assembling the frame, you can proceed to the sheathing with finishing material.