Forged gates and wickets: photos, pictures, drawings, sketches

Probably, there is not a single person who would remain completely indifferent when looking at an openwork metal pattern. Even more admirable is the massive pattern with which they are decorated, which are part of the entrance group.

The presence of massive metal gates, decorated with elegant patterns, is not a sign of a desire to isolate themselves from others, but they serve as an indicator that the owner has a taste and thinks about his own image. At the same time, forged gates are very well able to perform their main function - to protect the site from the penetration of uninvited guests, which is facilitated by height, the presence of sharp tips and strength. Also, almost any modern gate can be equipped with video surveillance systems, which will only improve their protective properties.

The range of gates and wickets - from classic to exclusive

There are a large number of companies offering high-quality forging services, which will make it possible to manufacture gates according to existing sketches. Also, almost any manufacturer of forged gates accepts for execution sketches and customer drawings, which contributes to the realization of any fantasy when decorating your own personal plot and enclosing it with a fence.

Timeless classic

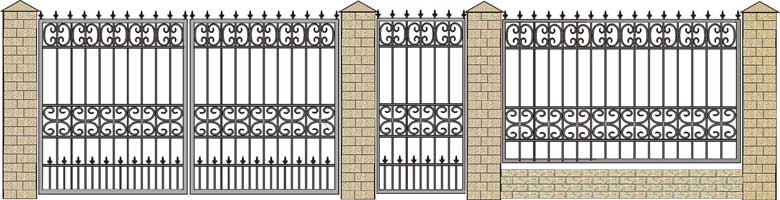

The most popular are gates and fences made in the classical style. The presented sketch gives a complete picture of how the entrance group will look like. A smooth fence with rare rods, which does not create the impression of being fenced off from the world, will be the choice of a person who is used to combining conciseness with practicality, but at the same time having taste. The arched vaults of the gates and the similar design of the wicket give a certain sophistication to the presented version.

Another reading of the classics, which practically does not differ from the previous version. The main difference of this model will be a larger number of decorative elements, which gives the whole ensemble a massiveness, which is hidden by rare rods. The line of openwork patterns, skipped along the top and bottom, visually limits the height of the gate and the gate, making them complete.

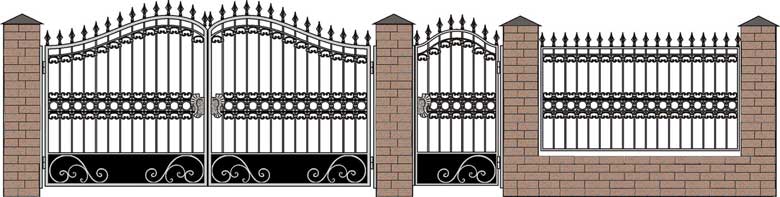

A sketch of a gate that combines the sophistication and beauty of a forged product and provides an increased level of security, achieved through sharp tips that end in the bars of the gate and fence. The arched vault visually enlarges the entire structure; a large number of patterned inserts is also a weighting element. The rolled execution of rods can give the whole ensemble beauty and unusualness.

For those who are not used to experimenting and are more inclined towards classic, smooth lines, manufacturers are ready to offer the options shown in the photo above. Such fences are in constant demand, because they are easy to perform, and look very presentable.

Another advantage of such options is the ability to mount the gate directly on the gate, unlike arched varieties, where the gate door does not fit. These types of gates can be decorated with patterns of varying degrees of complexity, have pointed peaks at the top or be completely smooth, which, of course, will deprive them of the brutality that the type of forged gate causes.

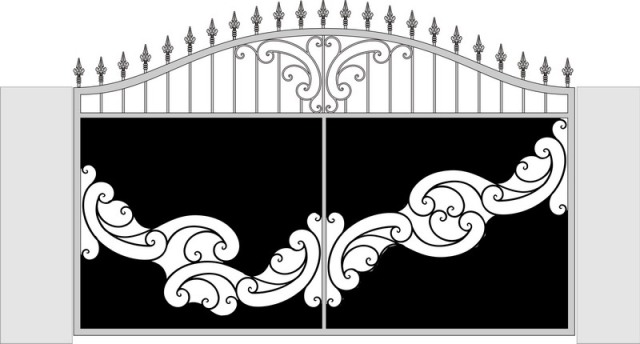

For those homeowners who value privacy and personal space, gates closed with sheet metal are recommended. In this case, there is the option of completely covering the door leaf and the fence, or closing only the lower part in the form of a forged fine mesh. Both options are distinguished by massiveness, monumentality, which speaks of the seriousness of the owner of this site and his concern for his own intimacy. The manufacture of such gates will require more metal, which will affect the cost, lead to a rise in price. But it's worth it, because these gates look beautiful and solid at the same time, but the openwork top and bottom do not create the impression of a "concrete wall".

Exclusive Models

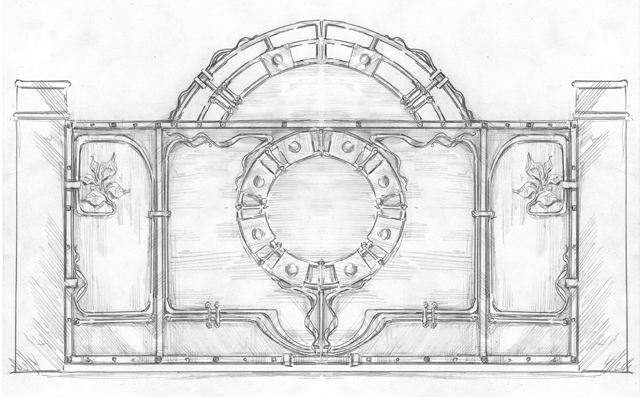

For people with sufficient financial resources or building solid country houses, it can be recommended to pay attention to more expensive models of gates and fences, which are classified as elite by most manufacturers.

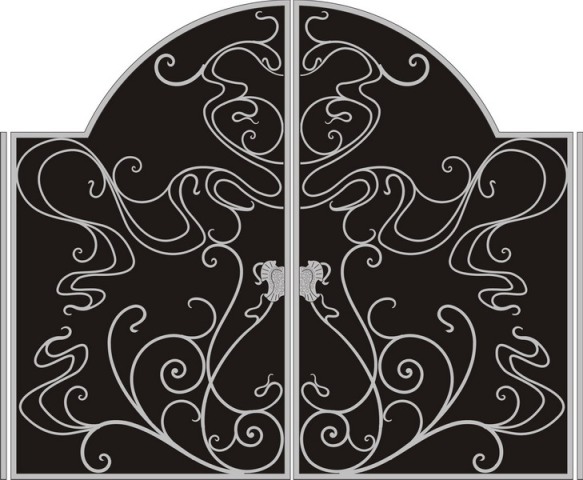

The main feature of these varieties of the question, which can be seen in the picture above, is their massiveness and closeness. In all models, sheet iron is used, which completely closes the front of the gate, a fence is similarly designed to create an integral ensemble. Also, an obligatory element that gives the gate status and exclusivity is the presence of forged or cast three-dimensional design elements that act as decorations placed on the gate. Another important detail is the complete set of ready-made gates with bolts and flashings.

Another option for the exclusive design of arched gates with the possibility of placing a gate due to the even foot of the vault. This model is characterized by rich decoration, many smooth lines of the pattern, creating airiness, which gives the gate a regal look without creating a feeling of massiveness. It should be remembered that such options, when most of the gates and fences are covered with a sheet of metal, are distinguished by their large weight, which requires preliminary calculation for the manufacture of the corresponding support pillars.

Wood and metal - a good combination

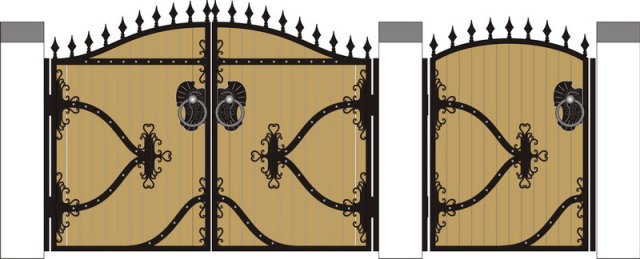

A separate place among the forged gates is occupied by models in which they successfully rallied l wood and metal. The gates themselves in this case are made of wood, a material that has been used to decorate a country house since ancient times, and all fasteners, edging, trim and just decoration elements are made by forging. Tips are also made in the same way, in case of a decision to create them.

Such a decision in the manufacture of the gate allows you to get not only reliable protection, but gives the entire entrance group a certain touch of eclecticism and following the roots.

Making forged gates with your own hands - the impossible is possible

If you want to get the original gate, which will be exclusive and will not be repeated by anyone in the area, there is an opportunity make them by hand. Despite the apparent complexity, this process is quite simple and straightforward.

The first step is to come up with a sketch of the future gate. It is best to draw pictures, which will help visualize the future result.

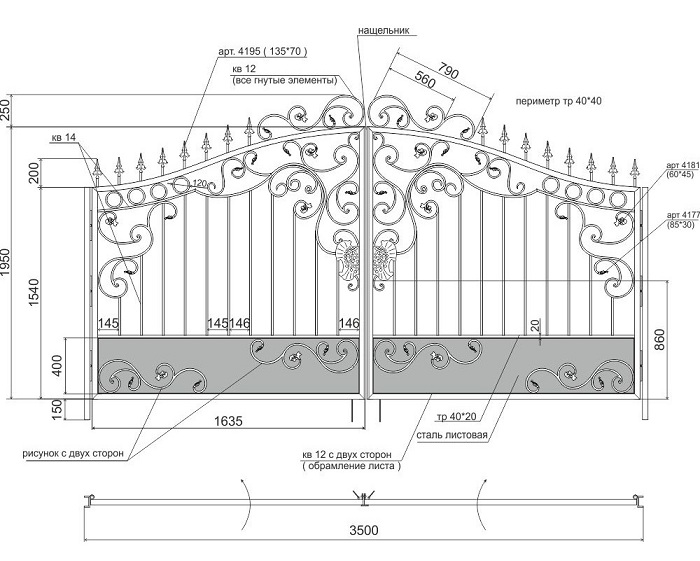

A pre-prepared sketch of the future gate will facilitate the work in the future

When developing a sketch, one should be guided by two postulates - strength and reliability. But we should not forget about beauty. It is important to first think over the geometry of the leaves of the future gate and fully calculate the overall dimensions of the future design.

Drawing - the first assistant in the manufacture of gates with their own hands

The tool needed to make the gate

When choosing a tool, you should choose what the gate will be. Either the entire manufacturing process will be independent, including metal forging, or forged elements will be purchased ready-made.

In the first case, additional forge, hammer, anvil. This path should be chosen only if you have practical skills in blacksmithing. Otherwise, it is better to prefer the second option.

To make a gate you will need:

- welding machine and a set of electrodes;

- powerful yews;

- angle grinder;

- brick;

- I-beam and profile pipe;

- sheets of metal, not less than 1 mm thick;

- cement mortar.

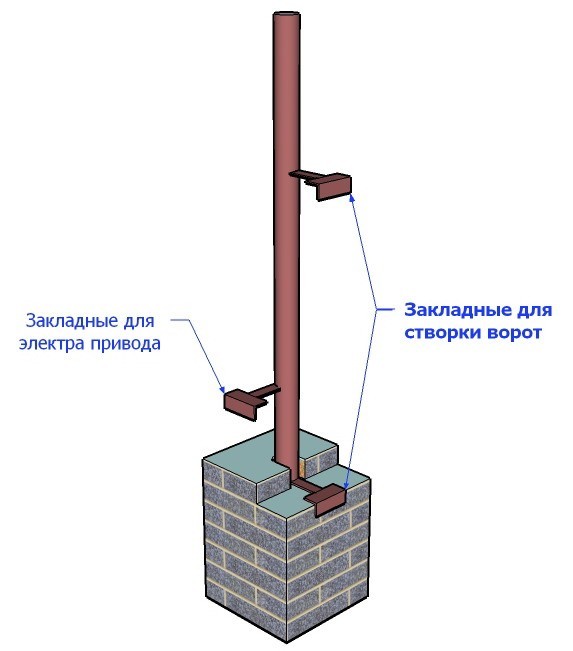

The first stage - supporting pillars

The first step will be the installation of support pillars, which must be strong enough to support the entire structure, which is distinguished by its considerable weight. The central part of the column will be a pipe with a diameter of at least 25 mm, and a facing brick will also be required.

Properly installed poles will guarantee the reliability of the entire structure.

It is important to remember that you must first calculate the thickness of the material, since the pipe will be lined with bricks. It is also necessary when digging a hole to leave a gap between the edge and the pipe of no more than 10 cm, so as not to cause the base to skew under the weight of the valves.

The final step in installing the pillar will be laying it with bricks.

The installation of the pillar consists in digging in the pipe, ramming the base using crushed stone and laying the pipe with bricks. Also at this stage, it will be necessary to weld the shank, special fasteners for the back curtains of the gate leaves. Sometimes only two tires are enough, but if the gate is supposed to be heavy, you can weld three to be sure.

Shutters are an important stage

For welding the sashes, a flat area should be chosen to prevent twisting of the frame parts. The prepared profile must be cut in accordance with the drawing, after which the frame is laid out on a flat area and all parts of the alignment are caught by spot welding.

When welding the frame, all parts must be placed on a flat surface to prevent twisting and deformation

After that, it is necessary to carry out control measurements, only then proceed to finishing welding with a continuous seam. Also, in the manufacture of sashes, it is necessary to weld all decorative elements in accordance with the drawing, while trying to weld in such a way as to make the seam as less noticeable as possible.

Painting

After welding the wings until the final installation, it is necessary to paint the resulting structure. Pre-treat the metal with an anti-corrosion compound, clean all visible welds, cover the gate with a primer layer after degreasing and apply a layer of paint. It is best to use a spray gun, which will ensure the evenness of the paint overlay.

Gate installation - the finish line

The final step is the installation of the gate. To do this, hinges should be welded to the ends of the wings, which should be located at the same distance as the reciprocal hinges on the poles. There is a small nuance of welding loops. The lower ones should be fastened in one direction, and the upper loops in the opposite direction. This is necessary to protect against the removal of the gate in the future.

At the final stage of production, decorative elements are welded and painting is carried out.

On the back of the leaves, it is necessary to weld brackets to accommodate the lock or provide for the option of placing modern locking elements.

The last step is to hang the gate on the hinges, for which you will need the help of a partner, which will help speed up and facilitate the process.

Making a forging machine

The video below provides instructions for making a cold forging machine with your own hands. Simple, fast and cost-effective. The video is hugely popular.