How to make a do-it-yourself visor over a polycarbonate entrance

A canopy over the front door made of polycarbonate or simply a "visor" performs two main functions:

- protection of the entrance group from rain and snow;

- creating shadows and absorbing ultraviolet radiation.

As a rule, wood, metal, glass, PVC, etc. are used as the material for the roof, but polycarbonate remains the most popular.

A plastic visor has a number of advantages:

- high resistance to mechanical stress;

- no need for constant care;

- ease of installation;

- high plasticity of polycarbonate sheets, which allows you to give the product any shape;

- low cost.

Types of polycarbonate - design features

There are two types of polycarbonate:

- cellular;

- monolithic.

Panels made of the first type of material are hollow two-layer sheets filled with longitudinal bridges. As a rule, this type is used in the manufacture of canopies, canopies, greenhouses and other construction.

The advantage of monolithic polycarbonate is its exceptional strength. Sheets of polymer plastic are transparent and resemble glass, but are able to withstand a load of 200 times greater. In this case, the weight of the structure will be half as much.

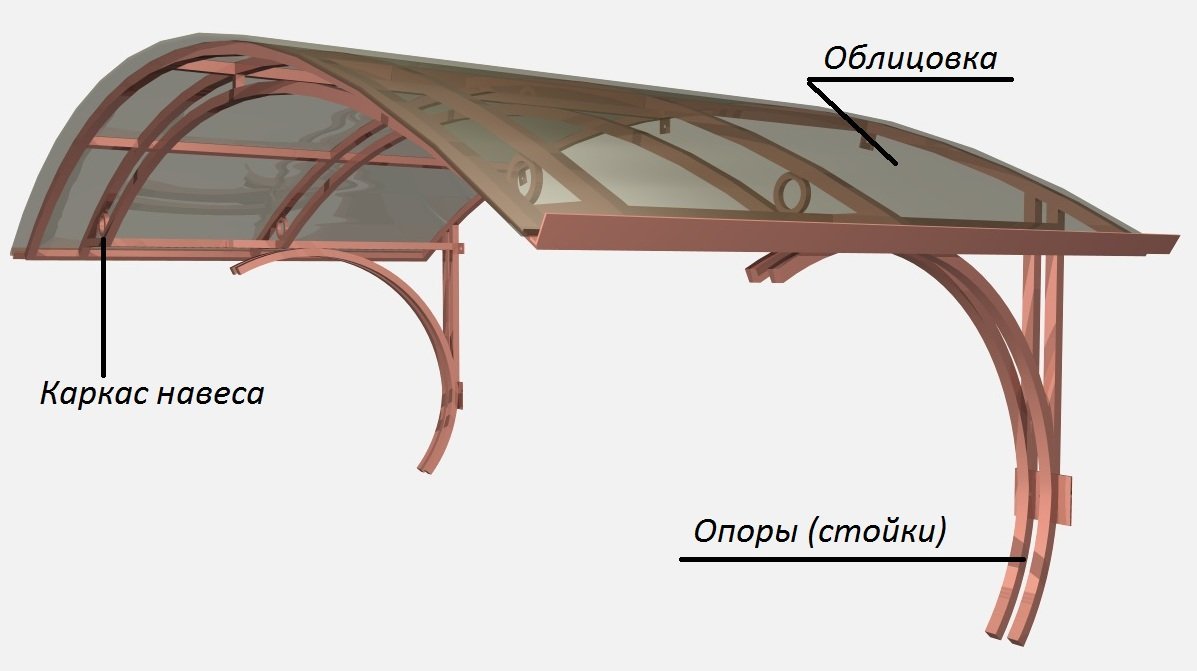

Polycarbonate canopy construction - canopy over the entrance

- frame- load-bearing structural element. For polycarbonate canopies, it is most often made of metal profiles. The main requirement is durability, the ability to withstand gusts of wind and withstand the weight of snow.

- lining. In this case, these are sheets of cellular or monolithic polycarbonate;

- supports and extensions. Necessary in order to redistribute the load from the visor to the base or walls. They are interchangeable elements.

Polycarbonate canopy shape

The shape of the polycarbonate visor primarily depends on the number of slopes:

- single slope;

- gable:

The most common forms of canopies for the entrance group:

- arched;

- visor in the form of a "house",

- with a semicircular slope;

- with a straight slope.

Do-it-yourself polycarbonate visor - manufacturing and installation

With a certain skill and skills, you may well. To make a simple visor located above the front door, you will need the following materials and tools:

- polycarbonate sheets;

- profile pipes for the manufacture of the frame;

- roulette;

- shovel;

- building level;

If the front posts of the canopy will rest on the ground, then it is necessary to dig two holes, the depth of which is 1–1.5 m. The distance between the holes is no more than 2 meters. In this case, it must be borne in mind that the width of the canopy should be greater than the width of the door above which it is built by about 60 cm (30 cm on both sides). Supports are inserted into the pits and concreted.

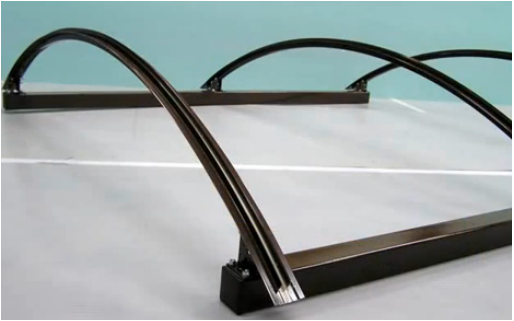

The distance between the arches of the frame is selected in accordance with what the snow load will be for a given region. The manufacturer's recommendations must also be taken into account.

Brackets are attached to the load-bearing beams according to the selected distances. Holes are drilled in the arch pipes, with the help of which they are fixed to the brackets. You should get the design shown in the photo.

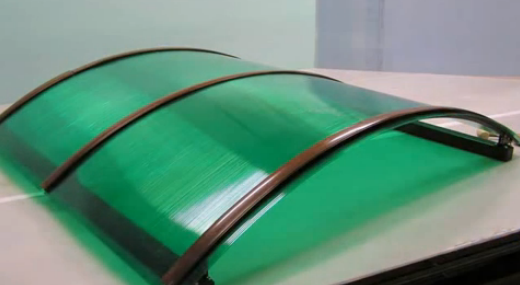

After the frame for the visor is ready, it is necessary to cut blanks from a polycarbonate sheet according to the dimensions of the canopy roof. The plastic panels are fixed with an upper clamping aluminum cover.

It is also important to choose the right thickness of the sheets: too thin polycarbonate can deform under load, and too thick will make the whole structure too heavy. It is recommended to use sheets with a thickness of 6 - 8 mm.

If you are installing polycarbonate with your own hands, then do not remove the packaging. This will protect the material from possible damage. The packaging is removed only after the canopy is fully installed.

An end profile is installed on the edges of the plastic sheets, which will ensure its waterproofing and prevent mechanical damage to the edges. If this is not done, then dust and dirt, getting inside the cellular polycarbonate, will reduce its light-transmitting properties. Water, freezing inside the leaf, gradually destroys it.

The resulting canopy is attached to the facade of the building on one side, and to the racks on the other. Fastening is carried out using metal brackets or welding.